Description

Detailed parameter table

| Parameter name | Parameter value |

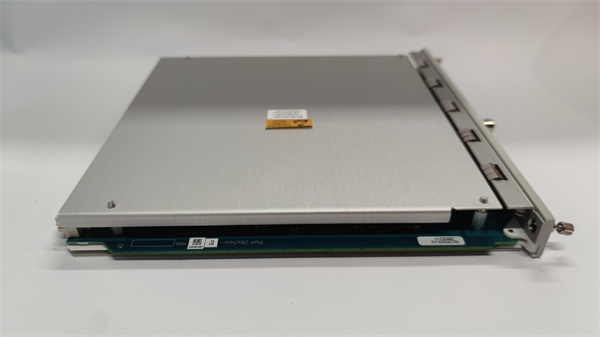

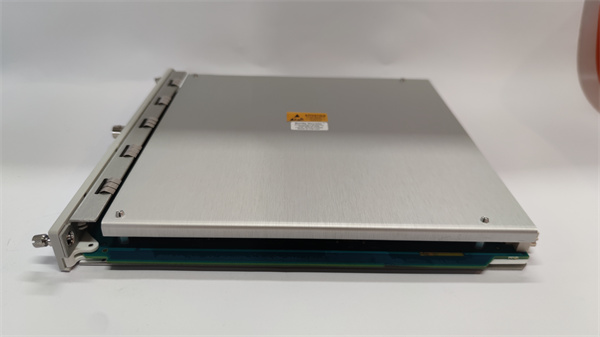

| Product model | 3500/54-03-00 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Machinery protection system module (vibration monitor) |

| Operating voltage | 24V DC ±10% |

| Operating temperature | -40°C to 85°C (-40°F to 185°F) |

| Relative humidity | 0% to 95% (non-condensing) |

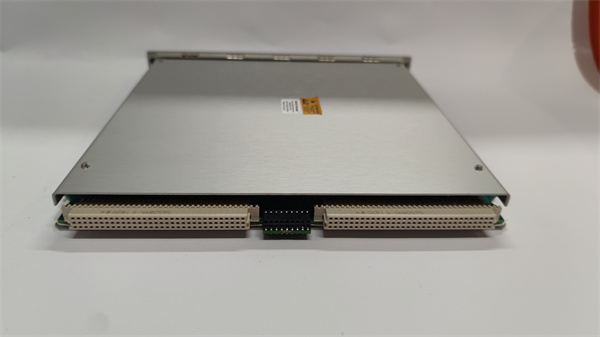

| Input channels | 8 differential vibration input channels |

| Output signals | 8 analog output channels (4-20mA DC) |

| Communication protocols | Ethernet/IP, Modbus TCP/IP, RS485 |

| Physical dimensions | 160mm x 100mm x 30mm (width x height x depth) |

| Installation method | 3500 rack-mount (compatible with Bently Nevada 3500 series racks) |

| Diagnostic capabilities | Real-time self-diagnostics, fault logging, and alarm notification |

| MTBF (Mean Time Between Failures) | >100,000 hours |

BENTLY 3500/54-03-00

Product introduction

The 3500/54-03-00 from Bently Nevada is a high-performance vibration monitoring module, serving as a critical component within the renowned 3500 machinery protection system series. Designed to deliver precise real-time data on rotating equipment health, this module acts as the “nerve center” for detecting early signs of mechanical issues such as imbalance, misalignment, or bearing wear.

As a key part of Bently Nevada’s industry-leading portfolio, the 3500/54-03-00 integrates seamlessly into larger automation systems, providing actionable insights that prevent unplanned downtime. Its advanced signal processing capabilities ensure accurate measurement of vibration amplitudes and frequencies, making it an indispensable tool for maintaining operational efficiency in critical industrial environments. By bridging sensor data and control systems, the 3500/54-03-00 empowers operators to make proactive decisions, safeguarding both equipment and production continuity.

Core advantages and technical highlights

Precision monitoring: The 3500/54-03-00 leverages Bently Nevada’s proprietary sensing technology to capture vibration data with exceptional accuracy, even in high-noise industrial settings. Its 8 input channels support a wide range of vibration sensors, ensuring compatibility with existing setups while delivering measurements that meet strict industry standards. This precision allows for early detection of subtle equipment anomalies, long before they escalate into costly failures.

Robust design: Built to thrive in harsh conditions, the 3500/54-03-00 operates reliably across extreme temperatures and humidity levels, making it suitable for demanding environments like refineries and power plants. Its rugged construction resists electrical interference and mechanical stress, ensuring consistent performance in the face of industrial wear and tear. This durability translates to reduced maintenance needs and a longer service life, maximizing return on investment.

Seamless integration: The 3500/54-03-00 supports multiple communication protocols, enabling effortless connectivity with DCS, SCADA, and other control systems. This flexibility allows it to fit into diverse automation architectures without requiring extensive reconfiguration. Additionally, its compatibility with the 3500 series rack system simplifies scalability—users can easily add more modules as their monitoring needs grow, ensuring the system evolves alongside their operations.

Typical application scenarios

In the power generation sector, the 3500/54-03-00 plays a vital role in monitoring turbine and generator health. By continuously tracking vibration patterns in these high-speed rotating machines, it helps plant operators detect issues like rotor imbalance or bearing degradation, preventing catastrophic failures that could halt electricity production. Its ability to operate in high-temperature environments near boilers and turbines makes it a trusted solution for ensuring uninterrupted power supply.

Within the oil and gas industry, the 3500/54-03-00 is deployed on compressors and pumps in both upstream and downstream operations. In offshore platforms, where equipment access is limited and failure risks are high, the module’s real-time alerts enable timely maintenance, avoiding costly shutdowns and environmental hazards. Similarly, in refineries, it monitors rotating equipment in distillation units, ensuring process stability and compliance with safety regulations.

In manufacturing facilities, the 3500/54-03-00 safeguards critical machinery such as motors and gearboxes on production lines. By identifying vibration-related issues early, it minimizes unplanned stoppages, protecting production schedules and reducing waste. Its compatibility with factory automation systems allows for integration into predictive maintenance programs, further optimizing operational efficiency.

BENTLY 3500/54-03-00

Related model recommendations

3500/42-01-00: A dual-channel vibration transducer module, complementary to the 3500/54-03-00 in 3500 series setups, ideal for systems requiring transducer power and signal conditioning.

3500/22-01-00: A key display module that pairs with the 3500/54-03-00 to provide visual real-time data, enhancing operator visibility of equipment status.

3500/92-01-00: A communication gateway module that extends the connectivity of the 3500/54-03-00 to enterprise-level systems, facilitating data analysis and reporting.

3500/15-01-00: A speed monitoring module often used alongside the 3500/54-03-00 to provide comprehensive machinery health data, including rotational speed and vibration metrics.

3500/61-01-00: A temperature monitoring module that complements the 3500/54-03-00 by adding thermal data to vibration analysis, offering a more complete picture of equipment condition.

3500/72-01-00: A relay module that works with the 3500/54-03-00 to trigger alarms or shutdowns based on vibration thresholds, enhancing system safety.

3500/05-01-00: The main rack power supply module, essential for powering the 3500/54-03-00 and other 3500 series modules in a rack configuration.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 3500/54-03-00, ensure the 3500 series rack is properly mounted in a clean, dry enclosure with adequate ventilation. Use ESD-safe tools to handle the module, as electrostatic discharge can damage internal components. Verify that the power supply meets the 24V DC ±10% requirement and that all wiring is correctly labeled to avoid connection errors. During installation, align the module with the rack guides and gently push until it locks into place, ensuring a secure fit to prevent signal interference.

Maintenance suggestions: For optimal performance, conduct monthly visual inspections of the 3500/54-03-00 to check for loose connections or signs of corrosion. Calibrate the module annually using Bently Nevada’s recommended calibration tools to maintain measurement accuracy. If a fault is detected, refer to the diagnostic logs accessible via the 3500 system software to pinpoint issues—common problems like communication errors can often be resolved by rechecking network connections. When replacing components, use only genuine Bently Nevada spare parts to ensure compatibility and avoid voiding the warranty.

Service and guarantee commitment

The 3500/54-03-00 is backed by Bently Nevada’s industry-leading 3-year warranty, covering defects in materials and workmanship. Our global network of technical support centers provides 24/7 assistance, with trained engineers available to help with installation, troubleshooting, and system optimization.

We offer comprehensive training programs to ensure your team can fully utilize the 3500/54-03-00’s capabilities, from basic operation to advanced data analysis. For extended support, customizable service agreements are available, including preventive maintenance visits and priority response times. Bently Nevada’s commitment to quality ensures that the 3500/54-03-00 delivers reliable performance throughout its lifecycle, backed by a company with decades of expertise in machinery protection.