Description

Detailed parameter table

| Parameter name | Parameter value |

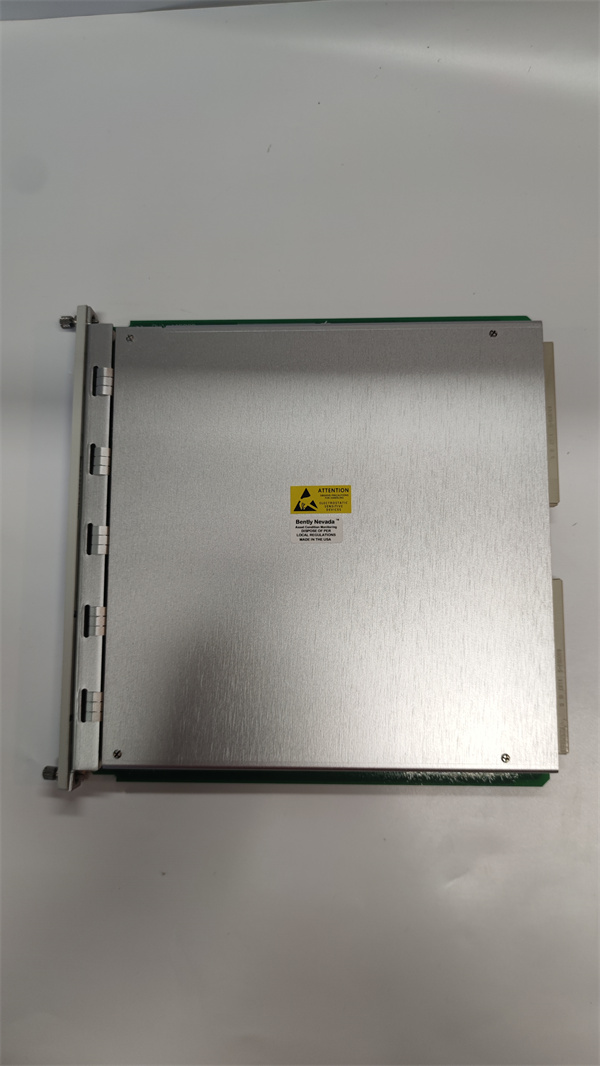

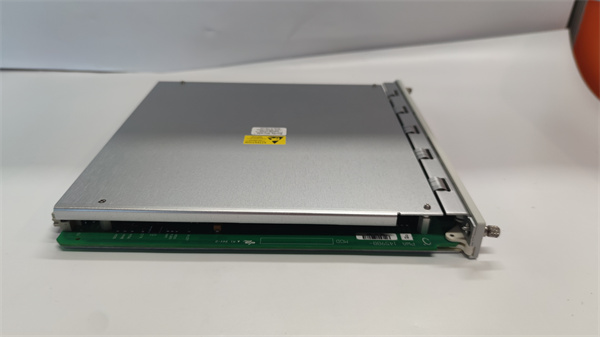

| Product model | 3500/65 145988-02 |

| Manufacturer | Bently Nevada |

| Product category | 16-channel relay output module |

| Electrical performance | 24V DC power supply (from 3500/91 190782-01 or 3500/15 127610-01); Power consumption: 9.2W max |

| Physical size | Width: 48.8mm, Height: 241.3mm, Depth: 242mm |

| Output channels | 16 Form C relay outputs (5A @ 250V AC, 3A @ 30V DC) |

| Relay configuration | Programmable as “Warning,” “Danger,” or “Shutdown”; configurable time delays (0-60s) |

| Interface type | Backplane connector; LED status indicators per channel; Terminal block connections |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing) |

| Installation method | Rack-mountable in 3500 series racks; Occupies 2 standard slots |

| Compatibility | Works with 3500/53M, 3500/44M 176449-03, 3500/22M 288055-01, and 170180-01-00 software (v7.0+) |

BENTLY 3500/65 145988-02

Product introduction

The Bently Nevada 3500/65 145988-02 is a high-density 16-channel relay output module, designed to serve as the action layer in 3500 series machinery protection systems. Unlike the standalone 1900/65A-00-00-02-00-01, which combines vibration monitoring and relay functionality in a single unit, this module focuses exclusively on executing protective actions—such as triggering alarms, shutdowns, or auxiliary equipment—based on commands from upstream controllers like the 3500/53M.

As a critical component in integrated monitoring systems, the 3500/65 145988-02 translates digital signals from vibration (3500/44M 176449-03) and temperature (3500/22M 288055-01) modules into physical responses. Its 16 programmable relays enable granular control over machinery behavior, supporting complex protection logic that links multiple fault conditions—for example, shutting down a turbine only when both high vibration and excessive bearing temperature are detected.

Powered by the 3500/91 190782-01 redundant supply, the module ensures reliable operation in safety-critical environments, from power plants to offshore platforms. Its rack-mount design and backplane integration make it ideal for large-scale systems, where the 1900/65A-00-00-02-00-01’s standalone architecture would be impractical for coordinating multi-point protection.

Core advantages and technical highlights

High-density relay capacity: With 16 Form C relays in a 2-slot rack footprint, the 3500/65 145988-02 maximizes protection points per unit space—critical for large systems monitoring multiple assets. This density far exceeds the 1900/65A-00-00-02-00-01’s 2 relays, enabling centralized control over an entire machinery train (e.g., turbine, gearbox, generator) with a single module.

Programmable flexibility: Each relay can be independently configured via 170180-01-00 software with custom labels, time delays, and logic triggers. For example, Relay 1 might activate a “High Vibration” alarm after a 2-second delay, while Relay 16 triggers an emergency shutdown instantly—capabilities absent in the 1900/65A-00-00-02-00-01’s fixed potentiometer-based setup.

System-wide integration: Unlike the 1900/65A-00-00-02-00-01, which operates in isolation, the 3500/65 145988-02 integrates with the 3500 backplane to receive commands from multiple monitoring modules. This allows it to execute cross-parameter actions, such as combining data from the 3500/44M 176449-03 (vibration) and 3500/22M 288055-01 (temperature) to prevent false shutdowns during transient conditions.

Rugged reliability: Built to withstand -40°C to +70°C temperatures and 5% – 95% humidity, the module outperforms the 1900/65A-00-00-02-00-01’s 0°C to +60°C range, making it suitable for extreme environments like arctic pipelines or desert power plants. Its relay contacts are rated for 5A @ 250V AC, supporting direct control of heavy machinery without external contactors.

Comparison with 1900/65A-00-00-02-00-01

| Feature | 3500/65 145988-02 | 1900/65A-00-00-02-00-01 |

| Primary function | 16-channel relay output module (action layer) | Single-channel vibration monitor with 2 relays (monitoring + action) |

| Channels | 16 Form C relays | 1 vibration input + 2 Form C relays |

| Configuration | Software-based (170180-01-00) with custom logic | Front-panel potentiometers (no software) |

| Integration | 3500 backplane (works with 3500/53M, 44M, 22M) | Standalone (no system integration) |

| Power | 24V DC (from 3500/91 or 3500/15) | 115/230V AC (direct mains) |

| Environmental range | -40°C to +70°C | 0°C to +60°C |

| Ideal application | Large-scale systems (turbines, compressors) | Standalone pumps, fans, small motors |

BENTLY 3500/65 145988-02

Typical application scenarios

In a combined-cycle power plant, the 3500/65 145988-02 acts as the central action module for a gas turbine system. It receives commands from the 3500/53M controller, which processes data from the 3500/44M 176449-03 (vibration) and 3500/22M 288055-01 (temperature). Relay 1 activates a warning siren when vibration exceeds 12 mm/s, Relay 2 opens a lube oil valve if bearing temperature rises above 90°C, and Relay 16 triggers a full shutdown if both conditions persist for 5 seconds—coordinated protection impossible with the 1900/65A-00-00-02-00-01’s standalone logic.

At an LNG processing facility, the module controls 16 critical valves and alarms across a compressor train. Its relays are programmed to isolate sections of the system based on fault severity: minor vibration triggers a local alarm (Relay 3), while a temperature spike in the aftercooler (detected by 3500/22M 288055-01) closes an emergency shutdown valve (Relay 8). The 3500/53M sequences these actions with 2-second delays to avoid pressure surges— a level of coordination beyond the 1900/65A-00-00-02-00-01’s capabilities.

In a pulp and paper mill, the 3500/65 145988-02 integrates with a hybrid system: 3500-series modules monitor the main paper machine, while 1900/65A-00-00-02-00-01 units protect auxiliary pumps. The 3500/65 145988-02’s Relay 10 triggers a 全厂警报 when any 1900/65A detects a “Danger” condition, ensuring operators are alerted to issues in both integrated and standalone equipment.

Related model recommendations

3500/53M: Controller that sends trigger signals to the 3500/65 145988-02 based on data from monitoring modules.

3500/44M 176449-03: Dynamic signal analyzer whose vibration data informs relay actions.

3500/22M 288055-01: Temperature module that provides thermal inputs for cross-parameter protection logic.

3500/91 190782-01: Redundant power supply ensuring uninterrupted relay operation in critical setups.

170180-01-00 software (v7.0+): Tool for configuring relay logic, delays, and labels.

3500/05-01-03-00-00-00: Rack interface module enabling remote monitoring of relay status.

1900/65A-00-00-02-00-01: Standalone vibration monitor that can integrate with the 3500/65 145988-02 in hybrid systems.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3500/65 145988-02 in 2 consecutive slots of the 3500 rack, near the 3500/53M controller for low-latency communication. Power off the system via the 3500/91 190782-01 before installation. Secure with screws torqued to 0.6 Nm, verifying backplane alignment. Connect relay outputs to alarm/shutdown devices via terminal blocks, using appropriately sized wiring for the load (e.g., 16AWG for 5A loads).

Commissioning steps: Power on via the 3500/91 190782-01 and confirm all relay LEDs illuminate. Use 170180-01-00 software to configure each relay: assign labels (e.g., “Turbine Shutdown”), set time delays, and map to trigger conditions (e.g., “3500/44M Channel 1 > 15 mm/s”). Test each relay by simulating its trigger condition and verifying the connected device activates/deactivates correctly. Confirm backplane communication by checking that relay status appears in the 3500/53M interface.

Maintenance suggestions: Inspect quarterly, checking terminal block connections for tightness and corrosion—clean with isopropyl alcohol if needed. Test relay contacts annually using a multimeter to verify continuity when energized; replace the module if any relay fails to close. Update firmware annually via 170180-01-00 software to maintain compatibility with 3500-series controllers. Unlike the 1900/65A-00-00-02-00-01, no potentiometer adjustments are needed, reducing calibration overhead.

Service and guarantee commitment

The 3500/65 145988-02 is backed by a 24-month warranty covering manufacturing defects, including relay contact failure, backplane communication issues, or LED malfunctions. During this period, Bently Nevada provides free repair or replacement, along with technical support for configuring relay logic and integrating with 3500-series modules.

Our service team offers 24/7 remote diagnostics via the 3500/05-01-03-00-00-00, helping identify faulty relays or configuration errors. Extended warranty options (up to 5 years) include annual relay contact testing and priority access to replacement modules. Built on Bently’s expertise in system-level protection, this module guarantees reliable execution of critical actions—essential for safeguarding high-value assets in integrated industrial environments.