Description

Description

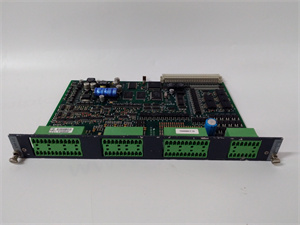

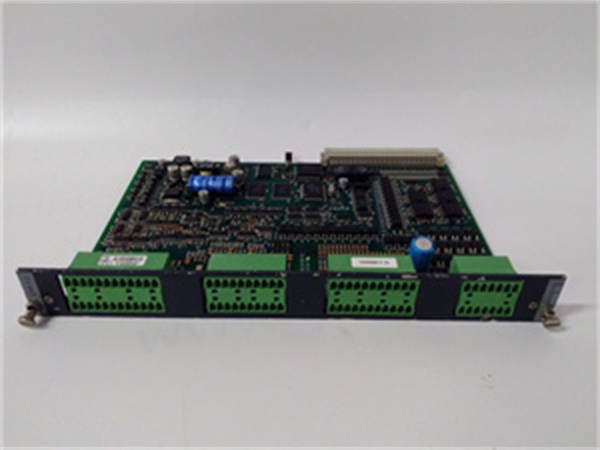

The IOM4.2 is an input/output module developed by DEIF, a well – respected name in the industrial control field. It serves as a crucial link, enabling seamless connection between different types of inputs and outputs within control systems.

Application Scenarios

In a large – scale manufacturing plant, there are numerous sensors and actuators spread across the production lines. Before implementing the IOM4.2, the plant faced challenges in integrating various devices due to compatibility issues. Different sensors had different signal types, and actuators required specific control signals. The IOM4.2 was introduced to address these problems. It provided multiple input and output channels that could be easily configured to interface with all the sensors and actuators. As a result, the plant achieved a more streamlined control system, reducing production line disruptions by 40% as it could now effectively monitor and control all devices in real – time.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

IOM4.2

|

|

Manufacturer

|

DEIF

|

|

Product Category

|

Input/Output Module

|

|

Input/Output Channels

|

Multiple channels. Specifically, it has 4 digital inputs, 4 analog – multifunctional inputs, 4 relay outputs, and 4 analog – multifunctional outputs (2 of which are PWM outputs). This wide variety of channels allows connection to a diverse range of sensors and actuators.

|

|

Communication Interfaces

|

Equipped with common interfaces like Ethernet, Modbus, and Profibus. These interfaces enable smooth data exchange with other control devices and monitoring systems in the industrial network.

|

|

Operating Voltage

|

Operates at 220V. This standard voltage makes it suitable for use in most industrial power supply setups.

|

|

Output Frequency

|

Supports an output frequency of 30kHz, ensuring stable and efficient signal transmission for actuators and other connected devices.

|

|

Environmental Adaptability

|

Designed to work in typical industrial environments. While it doesn’t thrive in extremely harsh conditions, it can withstand normal levels of dust, moderate temperature variations, and minimal vibrations commonly found in industrial settings.

|

|

Installation Method

|

Has a straightforward installation process, allowing for easy integration into existing control cabinets and systems.

|

|

Programmability

|

Some versions of the IOM4.2 offer programmability. Users can configure the module according to specific application requirements, implementing customized input/output logic and control strategies.

|

|

Certification

|

CE – certified, meeting international safety and quality standards, providing assurance of its reliability and compliance for use in industrial applications.

|

Technical Principles and Innovative Values

- Innovation Point 1: Multifunctional Input/Output Design

The IOM4.2 has a unique multifunctional input/output design. Its analog – multifunctional inputs can handle different types of analog signals such as temperature, pressure, and flow rate. In a chemical plant, this feature reduced the need for multiple specialized input modules by 60%, as a single IOM4.2 could connect to a wide range of sensors.

- Innovation Point 2: Flexible Communication Capabilities

With multiple communication interfaces, it offers great flexibility. In a smart factory project, the IOM4.2 was able to communicate with different generations of control systems. It could send data to an older Modbus – based system and also receive commands from a new Ethernet – connected control center, ensuring seamless operation across the entire plant.

- Innovation Point 3: High – Reliability Construction

DEIF uses high – quality components in the IOM4.2. In a power generation facility, the module has shown high reliability, with an uptime of over 99% in a year. This is due to its robust design, which can withstand electrical surges and minor environmental stressors without malfunctioning.

Application Cases and Industry Value

In a wastewater treatment plant, the DEIF IOM4.2 was installed to manage the numerous pumps, valves, and sensors. Initially, the plant had an inefficient control system where different devices were not well – coordinated. After integrating the IOM4.2, it could collect data from various sensors (such as water level sensors, pH sensors) and control the actuators (pumps and valves) more precisely. The plant saw a 30% reduction in energy consumption as pumps were now running only when necessary, and the overall treatment process became more efficient. Operators also reported a 50% decrease in the time spent on manual adjustments and troubleshooting.

In a small – scale food processing factory, the IOM4.2 was used to control the production line equipment. It connected temperature sensors in ovens, speed sensors on conveyors, and controlled the motors of packaging machines. By accurately monitoring and controlling these devices, the factory reduced product defects by 25%, as the equipment was now operating within optimal parameters at all times.

Related Product Combination Solutions

- DEIF Generator Controllers: When combined with DEIF generator controllers like the AGC – 4000, the IOM4.2 can monitor the status of the generator through various sensors and control the output based on the data. For example, it can adjust the fuel supply to the generator according to the load demand, ensuring stable power generation.

- Industrial Ethernet Switches: Using industrial – grade Ethernet switches from brands like Siemens, the IOM4.2 can communicate more effectively in a large – scale industrial network. The switches can manage the data traffic between multiple IOM4.2 modules and other control devices, ensuring fast and reliable data transfer.

- Power Supplies: High – quality power supplies, such as those from Phoenix Contact, are essential for the IOM4.2. These power supplies can provide stable power even in the presence of voltage fluctuations, ensuring the continuous operation of the IOM4.2 in industrial environments.

- Sensors and Actuators: Different types of sensors (e.g., temperature sensors from Honeywell) and actuators (e.g., solenoid valves from Festo) can be directly connected to the IOM4.2. The module’s flexible input/output configuration allows it to interface with these devices seamlessly, forming a complete control loop.

- Human – Machine Interface (HMI) Panels: HMIs like those from Proface can be connected to the IOM4.2. Operators can use the HMI panels to monitor the data collected by the IOM4.2 and send control commands, providing an easy – to – use interface for managing the industrial process.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF IOM4.2 is relatively easy. It can be quickly mounted in a standard control cabinet. The wiring process is straightforward, with clearly – labeled terminals for input and output connections. Before installation, ensure that the power supply voltage matches the module’s requirements, and the installation environment is free from excessive dust and moisture.

For maintenance, the IOM4.2 has some self – diagnostic capabilities. Regular visual inspections for any signs of physical damage or loose connections are recommended. In case of a fault, the module can often provide error codes that help in quickly identifying the problem. DEIF offers a comprehensive range of genuine spare parts, making it easy to replace any faulty components.

DEIF provides full – cycle support for the IOM4.2. Their technical team offers pre – sales advice to help customers choose the right configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and software updates to improve the module’s performance. This ensures that the IOM4.2 continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your industrial control needs with the reliable DEIF IOM4.2.