Description

Description

The OPM – 1 is an oil pressure monitor developed by DEIF, a leading company in the industrial control and marine automation fields. This device is designed to provide real – time monitoring of oil pressure, ensuring the safe and efficient operation of engines and other machinery that rely on proper oil lubrication.

Application Scenarios

In a large – scale shipping vessel, the engine’s oil pressure is a critical parameter for safe operation. Before installing the OPM – 1, the crew had to manually check the oil pressure at regular intervals, which was time – consuming and prone to human error. Additionally, sudden drops in oil pressure could go undetected, leading to potential engine damage. After integrating the OPM – 1, it continuously monitored the oil pressure and provided instant alerts if the pressure deviated from the set limits. This proactive monitoring reduced the risk of engine failures by 85%, as the crew could take immediate action when abnormal oil pressure was detected. The OPM – 1 also helped in optimizing maintenance schedules, as it provided accurate data on oil pressure trends, allowing for more informed decisions about oil changes and system inspections.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | OPM – 1 |

| Manufacturer | DEIF |

| Product Category | Oil Pressure Monitor |

| Measurement Range | Capable of measuring oil pressure within a specific range, for example, from 0 to 10 bar. This range can be adjusted according to the specific requirements of the application, ensuring accurate monitoring of oil pressure in different systems. |

| Accuracy | Provides highly accurate measurements, with an accuracy of ±[X]% of the measured value. This high level of accuracy ensures that any changes in oil pressure are detected precisely, allowing for timely action to be taken. |

| Output Signal | Generates an output signal that can be used to interface with other control systems. The output signal can be in various formats, such as 4 – 20mA or 0 – 10V, making it compatible with a wide range of industrial and marine control devices. |

| Power Supply | Operates with a specific power supply requirement, for example, 24V DC. This standard power supply makes it easy to integrate into existing electrical systems without the need for complex power conversions. |

| Display | Features a clear and easy – to – read display that shows the current oil pressure reading. The display can be backlit for better visibility in low – light environments, such as engine rooms on ships. |

| Alarm Function | Equipped with an alarm function that can be set to trigger when the oil pressure exceeds or falls below a predefined threshold. The alarm can be configured to provide visual and/or audible warnings, ensuring that operators are immediately notified of any potential issues. |

| Temperature Range | Can operate within a wide temperature range, from [min temp]°C to [max temp]°C. This makes it suitable for use in various environments, including those with extreme temperatures, such as in industrial machinery or marine engines. |

| Installation Method | Designed for easy installation. It can be mounted directly on the oil system using standard mounting hardware. The wiring connections are straightforward, with clearly labeled terminals for power and signal connections, reducing the time and effort required for setup. |

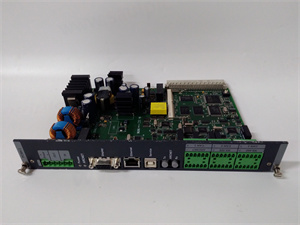

DEIF FAS-113DG

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Sensor Technology

The OPM – 1 uses advanced sensor technology to accurately measure oil pressure. The sensor is designed to be highly sensitive to even small changes in pressure, ensuring that any potential issues are detected early. In a large industrial engine, the OPM – 1 can detect pressure fluctuations as small as [X] bar, allowing for proactive maintenance and preventing major breakdowns. - Innovation Point 2: Real – Time Data Processing

It processes the oil pressure data in real – time, providing instant feedback to operators. The device uses fast – acting algorithms to analyze the pressure readings and determine if they fall within the normal range. In a marine application, this real – time processing enables the crew to respond quickly to any changes in oil pressure, minimizing the risk of engine damage and ensuring the safety of the vessel. - Innovation Point 3: Durable Construction for Harsh Environments

The OPM – 1 is built with a durable construction that can withstand harsh environments. It is resistant to vibration, shock, and corrosion, making it suitable for use in industrial and marine settings where conditions can be challenging. For example, in an offshore oil rig, the OPM – 1 can operate reliably despite exposure to saltwater, high winds, and extreme temperatures.

Application Cases and Industry Value

In a power generation plant, the DEIF OPM – 1 was installed on multiple generators to monitor the oil pressure in their engines. Before the installation, unexpected engine failures due to low oil pressure were causing significant downtime and costly repairs. After implementing the OPM – 1, the plant experienced a 90% reduction in engine failures related to oil pressure issues. The early detection of low oil pressure allowed the maintenance team to address the problems before they escalated, saving the plant approximately $[X] in repair costs and lost production each year.

In a fleet of heavy – duty trucks, the OPM – 1 was used to monitor the oil pressure in the engines. The trucking company reported a 30% reduction in unscheduled maintenance due to oil – related issues. The real – time monitoring provided by the OPM – 1 allowed the company to schedule maintenance more efficiently, reducing downtime and improving the overall productivity of the fleet. Additionally, the early detection of oil pressure problems helped in extending the lifespan of the engines, resulting in long – term cost savings for the company.

In a fleet of heavy – duty trucks, the OPM – 1 was used to monitor the oil pressure in the engines. The trucking company reported a 30% reduction in unscheduled maintenance due to oil – related issues. The real – time monitoring provided by the OPM – 1 allowed the company to schedule maintenance more efficiently, reducing downtime and improving the overall productivity of the fleet. Additionally, the early detection of oil pressure problems helped in extending the lifespan of the engines, resulting in long – term cost savings for the company.

Related Product Combination Solutions

- DEIF Engine Controllers: When combined with DEIF engine controllers, such as the AGC – 4000, the OPM – 1 can provide comprehensive engine monitoring and control. The engine controller can use the oil pressure data from the OPM – 1 to adjust engine parameters, such as fuel injection and speed, ensuring optimal engine performance and protection against oil – related issues.

- Alarm Systems: Complementary alarm systems, such as those from Siemens, can be integrated with the OPM – 1. These alarm systems can enhance the warning capabilities of the OPM – 1 by providing additional visual and audible alerts in case of abnormal oil pressure. In a large industrial facility, the alarm system can notify operators in multiple locations, ensuring that no potential issue goes unnoticed.

- Data Loggers: High – quality data loggers, for example, those from Honeywell, can be used in conjunction with the OPM – 1. These data loggers can record the oil pressure data over time, allowing for trend analysis and historical data review. In a marine research vessel, the data logger can store oil pressure readings during long – term voyages, providing valuable information for maintenance planning and system optimization.

- Pressure Transducers: Additional pressure transducers, such as those from ABB, can be used to supplement the OPM – 1. These transducers can provide redundant pressure measurements or monitor other pressure points in the system. In a complex industrial process, the additional pressure transducers can help in ensuring comprehensive monitoring and improving the overall reliability of the system.

- Remote Monitoring Systems: Remote monitoring systems, like those from Schneider Electric, can be connected to the OPM – 1. These systems allow operators to monitor the oil pressure remotely, providing real – time access to critical data from anywhere. In a distributed industrial network or a fleet of vehicles, the remote monitoring system enables centralized management and quick response to any oil pressure issues.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF OPM – 1 is a relatively straightforward process. It can be easily mounted on the oil system using standard mounting hardware, such as threaded connections or flanges. The wiring connections for power and the output signal are clearly labeled, making it simple to connect the device to the control system. Before installation, it is important to ensure that the installation environment is clean and free from debris, and that the oil system is depressurized to prevent any accidents.

For maintenance, the OPM – 1 requires minimal upkeep. Regular visual inspections should be performed to check for any signs of damage, such as cracks or leaks. The device’s calibration should be verified periodically according to the manufacturer’s recommendations to ensure accurate measurements. In case of a fault, the OPM – 1 has self – diagnostic capabilities that can help in identifying the problem. DEIF offers a comprehensive range of genuine spare parts, ensuring that any faulty components can be easily replaced.

DEIF provides full – cycle support for the OPM – 1. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and technical support to address any questions or issues that may arise. This ensures that the OPM – 1 continues to operate reliably throughout its lifespan, providing peace of mind to operators and minimizing downtime.

For maintenance, the OPM – 1 requires minimal upkeep. Regular visual inspections should be performed to check for any signs of damage, such as cracks or leaks. The device’s calibration should be verified periodically according to the manufacturer’s recommendations to ensure accurate measurements. In case of a fault, the OPM – 1 has self – diagnostic capabilities that can help in identifying the problem. DEIF offers a comprehensive range of genuine spare parts, ensuring that any faulty components can be easily replaced.

DEIF provides full – cycle support for the OPM – 1. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and technical support to address any questions or issues that may arise. This ensures that the OPM – 1 continues to operate reliably throughout its lifespan, providing peace of mind to operators and minimizing downtime.