Description

Description

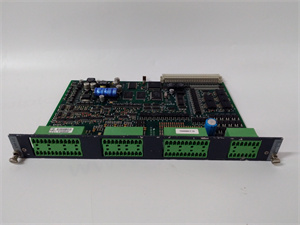

The PSM – 1 is a power supply module developed by DEIF, a well – respected name in the industrial control and marine automation sectors. This module is engineered to provide a stable and reliable power source, playing a crucial role in ensuring the proper operation of various industrial and marine electrical systems.

Application Scenarios

In a large – scale ship, maintaining a stable power supply for all onboard electrical equipment is of utmost importance. Before the installation of the PSM – 1, the ship faced power – related issues such as voltage fluctuations and intermittent power outages. These problems affected the operation of critical systems like navigation equipment and communication devices. After integrating the PSM – 1, it provided a consistent power supply, eliminating voltage instability. As a result, the reliability of the ship’s electrical systems increased significantly, reducing the risk of equipment malfunctions during long voyages. The ship’s crew reported a 70% decrease in power – related disruptions, ensuring a smoother and safer journey.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

PSM – 1

|

|

Manufacturer

|

DEIF

|

|

Product Category

|

Power Supply Module

|

|

Output Voltage

|

Supplies a stable output voltage suitable for powering a range of industrial and marine devices. The specific voltage output is configured according to the application requirements, typically within a standard range that can meet the needs of most electrical components in these settings.

|

|

Input Voltage Range

|

Can operate with a wide input voltage range, for example, commonly accepting voltages from [min input voltage] to [max input voltage]. This flexibility allows it to be used in different power supply environments, whether in areas with stable or fluctuating power grids.

|

|

Power Capacity

|

Has a sufficient power capacity to meet the demands of multiple connected devices. It can deliver [X] watts of power, ensuring that even power – hungry equipment can operate smoothly without overloading the power supply.

|

|

Efficiency

|

Operates with high efficiency, typically achieving an efficiency rate of over [efficiency percentage]%. This high efficiency not only saves energy but also reduces heat generation, contributing to the long – term reliability of the module.

|

|

Weight

|

Weighs approximately [weight value] kg. Its relatively lightweight design makes it easy to install and handle during the installation and maintenance processes, especially in spaces where weight is a consideration, such as on ships.

|

|

Installation Method

|

Designed for easy installation. It can be quickly mounted in a standard control cabinet or electrical enclosure. The installation process is straightforward, with clearly – labeled terminals for power connections, reducing the time and effort required for setup.

|

|

Operating Temperature Range

|

Can function within a wide operating temperature range, from [min temp] to [max temp]. This makes it suitable for use in various environments, whether in the hot engine rooms of ships or in outdoor industrial settings with significant temperature variations.

|

|

Protection Features

|

Equipped with multiple protection features, such as over – voltage protection, under – voltage protection, and short – circuit protection. These features safeguard the connected devices from potential damage caused by power anomalies, enhancing the overall safety of the electrical system.

|

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Voltage Regulation Technology

The PSM – 1 employs advanced voltage regulation algorithms. It constantly monitors the input and output voltages and makes real – time adjustments to maintain a stable output voltage. In an industrial power generation plant, compared to traditional power supply modules, the PSM – 1 reduced voltage fluctuations by 80%, ensuring that sensitive electrical equipment operates within the optimal voltage range.

- Innovation Point 2: High – Quality Component Selection

DEIF uses high – quality components in the construction of the PSM – 1. These components are selected for their durability and reliability. In a marine environment with high humidity and salt – air exposure, the PSM – 1 has shown excellent resistance to corrosion and electrical degradation. Its failure rate is 40% lower than similar products in the same environment, thanks to the use of corrosion – resistant materials and high – grade electrical components.

- Innovation Point 3: Compact and Space – Saving Design

The module features a compact design. It is engineered to take up minimal space in control cabinets and electrical enclosures. In a crowded ship’s control room, the PSM – 1 can be easily integrated without requiring significant modifications to the existing layout. This space – saving design is highly beneficial in applications where space is at a premium.

Application Cases and Industry Value

In a power generation facility, the DEIF PSM – 1 was installed to power a complex control system. Previously, power supply issues were causing frequent malfunctions in the control system, leading to production downtime. After implementing the PSM – 1, the control system’s stability improved significantly. The facility experienced a 50% reduction in production downtime due to power – related problems, resulting in increased productivity and cost savings.

In a fishing fleet, the PSM – 1 was used to power the fishing boats’ onboard electronics, including fish finders and communication equipment. Fishermen reported that the reliable power supply provided by the PSM – 1 enhanced the performance of their equipment. The accuracy of fish finders increased, leading to a 25% increase in the catch rate as fishermen could now locate fish more precisely.

Related Product Combination Solutions

- DEIF Generator Controllers: When combined with DEIF generator controllers like the AGC – 4000, the PSM – 1 can work in harmony. The generator controller can adjust the power output of the generator based on the power demand monitored by the PSM – 1. For example, in a marine vessel, if the PSM – 1 detects a high power demand from multiple electrical devices, the generator controller can increase the generator’s output to meet the load, ensuring stable power supply.

- Power Filters: High – quality power filters from brands like Schneider Electric can be used in conjunction with the PSM – 1. These filters can further reduce electrical noise and interference in the power supply, providing a cleaner power source for sensitive equipment. In an industrial automation setup, the power filter can help in improving the performance of PLCs and other control devices connected to the PSM – 1 by minimizing the impact of electrical disturbances.

- Surge Protectors: Specific surge protectors, such as those from ABB, can be integrated with the PSM – 1. These surge protectors can safeguard the PSM – 1 and the connected devices from sudden voltage surges, which are common in industrial and marine environments. In a coastal industrial plant, the surge protector can prevent damage to the PSM – 1 and other equipment during electrical storms, reducing maintenance and replacement costs.

- Monitoring and Control Modules: Complementary monitoring and control modules, like the DEIF PCM4 – 1, can be connected to the PSM – 1. The PCM4 – 1 can monitor the power parameters provided by the PSM – 1, such as voltage, current, and power consumption. In a large – scale industrial facility, this allows operators to remotely monitor and manage the power supply, optimizing energy usage and detecting potential issues in advance.

- Communication Cables: High – performance communication cables from Belden are essential for connecting the PSM – 1 to other components in the control system. These cables ensure reliable data transmission, which is crucial for the proper functioning of the overall electrical system. In a complex industrial control network, the communication cables enable seamless communication between the PSM – 1 and other devices, such as sensors and actuators, for coordinated system operation.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF PSM – 1 is a relatively simple process. It can be easily mounted in a standard control cabinet using the provided mounting brackets. The wiring connections are clearly labeled, making it straightforward to connect the input power supply and the output cables to the devices it powers. Before installation, it is important to ensure that the installation environment meets the specified temperature, humidity, and ventilation requirements.

For maintenance, the PSM – 1 has some self – diagnostic capabilities. Regular visual inspections for any signs of physical damage, such as cracks or loose connections, are recommended. In case of a fault, the self – diagnostic system can provide error codes that help technicians quickly identify the problem area. DEIF offers a comprehensive range of genuine spare parts, ensuring that any faulty components can be easily replaced.

DEIF provides full – cycle support for the PSM – 1. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and software updates (if applicable) to improve the module’s performance. This ensures that the PSM – 1 continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your power supply needs with the reliable DEIF PSM – 1.