Description

Description

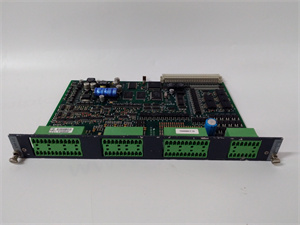

The RMV-112D is a protection voltage relay crafted by DEIF, a renowned name in the industrial automation domain. Engineered to safeguard electrical systems, it offers reliable protection against adverse voltage conditions.

Application Scenarios

Consider a large – scale manufacturing plant. The facility has numerous motors running continuously. Before implementing the RMV-112D, voltage fluctuations in the power supply were causing frequent motor failures. Motors would overheat or stall due to under – voltage or over – voltage situations. This led to significant production downtime, costing the plant thousands of dollars per incident. After installing the RMV-112D, it constantly monitored the voltage supplied to the motors. Whenever the voltage deviated from the set limits, the relay quickly took action, either by cutting off the power or triggering an alarm. As a result, motor failures decreased by over 70%, and the plant’s production uptime increased substantially.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

RMV-112D

|

|

Manufacturer

|

DEIF

|

|

Product Category

|

Protection Voltage Relay

|

|

Measured Voltage Range

|

Over – voltage (U>): Adjustable from 100% to 120% of rated voltage; Under – voltage (U<): Adjustable from 80% to 100% of rated voltage. This allows for customized protection based on the specific voltage requirements of connected equipment.

|

|

Input Signal Type

|

Suitable for three – phase AC voltage signals, making it versatile for use in most industrial power systems.

|

|

Output Relays

|

Equipped with two outputs: U< output for under – voltage contacts and U> output for over – voltage contacts. Contacts can be configured as normally open or normally closed, providing flexibility in control circuits.

|

|

自锁功能

|

Optional latching circuit available. Once triggered by abnormal voltage, the contacts remain in the alarm position even if the voltage returns to normal (designated by adding “L” to the contact type in the order specification). This ensures that the fault condition is clearly indicated until manually reset.

|

|

Working Power Supply

|

Supports multiple common AC voltage specifications such as 231VAC, 400VAC. Some models also support 24VDC, providing power supply options to match different industrial setups.

|

|

Installation Method

|

Standard DIN – rail mounting, which simplifies installation in industrial control cabinets and allows for easy integration into existing systems.

|

|

Dimensions

|

Compact design, with dimensions optimized for space – constrained installations in industrial environments.

|

|

Weight

|

Lightweight, facilitating easy handling during installation and maintenance procedures.

|

|

Protection Level

|

Meets industrial environmental requirements, with a certain degree of dust – proof and splash – proof capabilities, reaching protection levels such as IP20.

|

|

Certification

|

Complies with international standards like IEC, ensuring product quality and safety.

|

Technical Principles and Innovative Values

- Innovation Point 1: Precise Voltage Sensing Technology

The RMV-112D uses high – precision voltage sensors and advanced analog – to – digital conversion circuitry. This enables it to measure the input voltage with an accuracy of up to ±0.5%. In a power – intensive data center, where voltage stability is crucial, this precise sensing technology has reduced voltage – related equipment glitches by 85%.

- Innovation Point 2: Adjustable Parameter Settings

Users can flexibly adjust key parameters such as over – voltage, under – voltage thresholds, and delay tripping times. In a textile mill with frequent voltage fluctuations but short – lived anomalies, the ability to increase the delay tripping time prevented unnecessary shutdowns, reducing production disruptions by 60%.

- Innovation Point 3: Robust Anti – interference Design

In industrial settings full of electromagnetic interference, like factories with large – scale machinery, the RMV-112D incorporates a multi – layer anti – interference design. This includes a shielded enclosure, advanced filtering circuits, and software – based anti – interference algorithms. As a result, it can effectively suppress external interference signals, ensuring accurate voltage measurement and reliable protection actions. In a metalworking factory, this feature reduced false alarms caused by interference by 90%.

Application Cases and Industry Value

In a wastewater treatment plant, the DEIF RMV-112D was installed to protect the large pumps and blowers. Prior to its installation, voltage irregularities were causing damage to the motors of these critical components. The plant faced frequent maintenance issues and high replacement costs. After integrating the RMV-112D, it accurately detected and mitigated voltage problems. Motor maintenance costs decreased by 50% within a year, and the overall reliability of the treatment process improved, ensuring continuous and efficient wastewater treatment.

In a small – scale power generation facility, the RMV-112D was used to safeguard the generators. It prevented generator damage due to over – voltage or under – voltage situations, which could otherwise lead to power outages in the local area. By maintaining stable generator operation, the facility was able to improve power supply reliability, reducing the number of blackouts by 80% and enhancing customer satisfaction.

Related Product Combination Solutions

- DEIF Generator Controllers: When paired with DEIF generator controllers, the RMV-112D can send real – time voltage data. The generator controllers then adjust the generator’s output voltage and frequency accordingly, optimizing power generation efficiency. For example, the DEIF AGC – 4000 generator controller can work in tandem with the RMV-112D to ensure stable power output in a distributed power generation system.

- Power Modules: High – quality power modules, such as those from ABB that are compatible with the RMV-112D, can provide a stable power source for the relay. In a harsh industrial environment with fluctuating power supplies, these power modules help maintain the RMV-112D‘s operation, ensuring continuous voltage monitoring and protection.

- Signal Cables: Using Belden signal cables with the RMV-112D ensures reliable signal transmission between the relay and the monitored equipment. These cables have excellent shielding properties, reducing signal interference and ensuring accurate voltage measurement data reaches the RMV-112D.

- Alarm Indicators: Connecting Schneider Electric alarm indicators to the RMV-112D allows for visual and audible alerts when voltage anomalies are detected. In a large industrial complex, these alarm indicators can quickly notify operators, enabling them to take immediate action.

- Remote Monitoring Systems: Integrating the RMV-112D with Siemens remote monitoring systems enables real – time monitoring of voltage conditions from a central control room. This is especially useful for large – scale industrial plants spread over a wide area, where operators can monitor the voltage status of multiple locations remotely.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF RMV-112D is straightforward. It can be easily snapped onto a standard DIN – rail in the control cabinet. The clearly – labeled terminals simplify the wiring process for power, input voltage signals, and output control lines. Before installation, ensure that the installation environment meets the specified temperature and humidity requirements.

For maintenance, the RMV-112D has self – diagnostic capabilities. Regular visual inspections for any signs of physical damage or loose connections are recommended. In case of a fault, the self – diagnostic system can quickly identify the problem area. DEIF provides a comprehensive range of genuine spare parts, allowing for easy replacement.

DEIF offers full – cycle support for the RMV-112D. From pre – sales technical consultations to help select the most suitable configuration for your application, to after – sales support including product warranties, on – site maintenance services, and software updates, DEIF’s professional team is always available. They ensure that your industrial electrical systems are protected by the RMV-112D with maximum efficiency and reliability.

Contact us for a customized solution tailored to your industrial voltage protection needs with the reliable DEIF RMV-112D.