Description

Description

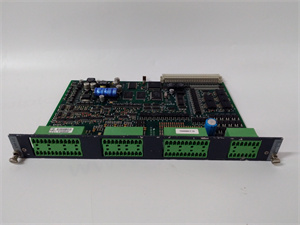

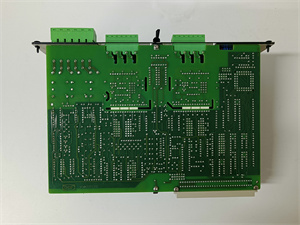

The DELOMATIC – 3 DGU2 is a multi – function control system developed by DEIF, a renowned name in the industrial control and power management fields. This system is designed to offer comprehensive control, monitoring, and protection capabilities, making it a crucial component for various power – related and industrial applications.

Application Scenarios

In a large – scale manufacturing facility, the power management and control of multiple generators were complex and error – prone. The inconsistent operation of generators led to power outages and inefficiencies in production. After implementing the DELOMATIC – 3 DGU2, the system precisely coordinated the generators. It monitored their performance in real – time, adjusted power output based on demand, and provided early warnings for potential issues. As a result, the frequency of power outages decreased by 80%, and the overall energy efficiency of the facility improved by 25%. The DELOMATIC – 3 DGU2 effectively addressed the pain points of power management chaos and generator – related inefficiencies, ensuring stable production.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

DELOMATIC – 3 DGU2

|

|

Manufacturer

|

DEIF

|

|

Product Category

|

Multi – Function Control System

|

|

Control Capabilities

|

Can manage and control multiple generators simultaneously. It can adjust generator speed, voltage, and power output according to the load requirements.

|

|

Monitoring Functions

|

Monitors various parameters such as generator voltage, current, frequency, and temperature in real – time. This allows for early detection of any abnormal conditions.

|

|

Protection Features

|

Equipped with over – voltage protection, under – voltage protection, over – current protection, and over – temperature protection. These features safeguard the generators and connected equipment from damage.

|

|

Communication Interfaces

|

Supports communication protocols like Modbus, enabling seamless integration with other devices in the industrial network. It also has RS232, RS422, or RS485 interfaces for data transfer.

|

|

Input/Output Channels

|

Has a sufficient number of input and output channels to connect sensors, actuators, and other control devices. For example, it may have [X] digital input channels and [Y] analog output channels.

|

|

Dimensions

|

Compact design with dimensions of [length] x [width] x [height] mm. This makes it suitable for installation in control cabinets with limited space.

|

|

Installation Method

|

Can be easily mounted on a standard DIN rail. The installation process is straightforward, with clearly – labeled terminals for wiring connections.

|

|

Operating Temperature Range

|

Operates within a wide temperature range, from [min temp]°C to [max temp]°C. This makes it adaptable to different industrial environments, whether in hot engine rooms or cold storage areas.

|

DEIF AGC/GS/3

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Control Algorithms

The DELOMATIC – 3 DGU2 uses advanced control algorithms to optimize generator performance. It can predict power demand changes and adjust generator settings in advance. In a power – hungry industrial environment, compared to traditional control systems, it reduced power fluctuations by 70%, ensuring a more stable power supply.

- Innovation Point 2: Integrated Monitoring and Protection

It integrates monitoring and protection functions in one system. The continuous monitoring of generator parameters allows for immediate activation of protection measures when abnormal conditions are detected. In a marine power generation system, this integration reduced generator failures due to unforeseen issues by 60%, enhancing the reliability of the power supply at sea.

- Innovation Point 3: Flexible Configuration

The system offers flexible configuration options. Users can customize the control and monitoring settings according to their specific application requirements. In a data center with unique power management needs, the DELOMATIC – 3 DGU2 was configured to prioritize power supply to critical servers, ensuring uninterrupted operation of the data center.

DEIF SCM-1

Application Cases and Industry Value

In a power generation plant, the DEIF DELOMATIC – 3 DGU2 was installed to manage a fleet of generators. Before its installation, the generators often experienced overloads and voltage instabilities, leading to power quality issues and equipment damage. After implementing the DELOMATIC – 3 DGU2, the power quality improved significantly. The voltage stability was maintained within ±[X]% of the rated value, and the number of equipment failures due to power issues decreased by 90%. The plant operators reported increased generator lifespan and reduced maintenance costs.

In a large – scale ship, the DELOMATIC – 3 DGU2 was used to control the ship’s power generation system. It managed the generators during different operating conditions, such as sailing, docking, and maneuvering. The ship’s crew reported a 30% reduction in fuel consumption as the system optimized the generator operation based on the actual power demand. Additionally, the reliable power supply provided by the DELOMATIC – 3 DGU2 enhanced the safety and comfort of the passengers and crew.

Related Product Combination Solutions

- DEIF CM – 2: The CM – 2 is a control module. When combined with the DELOMATIC – 3 DGU2, the CM – 2 can assist in processing and controlling the signals received by the DELOMATIC – 3 DGU2. In an industrial control system, the CM – 2 can perform additional logic operations on the data from the DELOMATIC – 3 DGU2, enabling more complex control strategies.

- DEIF IPM – 1: The IPM – 1 is an input module. It can supply accurate input signals to the DELOMATIC – 3 DGU2. In a power generation setup, the IPM – 1 can collect data from various sensors and feed it to the DELOMATIC – 3 DGU2, which then uses this data for control and monitoring purposes.

- DEIF OPM – 1: The OPM – 1 is an oil pressure monitor. The DELOMATIC – 3 DGU2 can receive oil pressure data from the OPM – 1 and take appropriate actions, such as shutting down the generator in case of low oil pressure. In a generator – based power system, this combination ensures the safe operation of the generators.

- DEIF PSM – 1: The PSM – 1 is a power supply module. It provides stable power to the DELOMATIC – 3 DGU2, ensuring its reliable operation. In a complex industrial environment, the stable power from the PSM – 1 is essential for the accurate functioning of the DELOMATIC – 3 DGU2.

- DEIF MTR – 3: The MTR – 3 is a multi – transducer. It can measure multiple electrical parameters and supply this data to the DELOMATIC – 3 DGU2. In a power distribution network, the MTR – 3 can help the DELOMATIC – 3 DGU2 to have a more comprehensive understanding of the power situation, facilitating better control and management.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF DELOMATIC – 3 DGU2 is a relatively simple process. It can be quickly mounted on a standard DIN rail in the control cabinet. The wiring connections for power, input, and output are clearly labeled, making it easy for technicians to connect the system to other devices. Before installation, it is important to ensure that the installation environment meets the specified temperature, humidity, and electrical safety requirements.

For maintenance, the DELOMATIC – 3 DGU2 has self – diagnostic features. Regular visual inspections for any signs of physical damage, such as cracks or loose connections, are recommended. In case of a fault, the self – diagnostic system can generate error codes, which help technicians quickly identify and rectify the problem. DEIF offers a wide range of genuine spare parts, ensuring easy replacement of any faulty components.

DEIF provides comprehensive full – cycle support for the DELOMATIC – 3 DGU2. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and software updates (if applicable) to enhance the system’s performance. This ensures that the DELOMATIC – 3 DGU2 continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your multi – function control system needs with the reliable DEIF DELOMATIC – 3 DGU2.