Description

Description

The LSU-112DG is a sophisticated load sharing and protection controller brought to you by DEIF, a trusted name in industrial control solutions. Engineered to manage the distribution of electrical loads, it plays a pivotal role in ensuring the smooth operation of power systems.

Application Scenarios

In a large – scale data center, continuous and stable power supply is crucial. Multiple diesel generators are on standby to provide backup power during outages. Before the adoption of the LSU-112DG, the generators often faced uneven load distribution when operating in parallel. Some generators were overloaded, leading to frequent breakdowns and reduced lifespan, while others were under – utilized. The LSU-112DG was installed to solve this problem. It precisely monitored and regulated the load among the generators, ensuring each unit carried an appropriate share. As a result, the incidence of generator failures due to overloading decreased by over 60%, and the overall power supply reliability of the data center significantly improved.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

LSU-112DG

|

|

Manufacturer

|

DEIF

|

|

Product Category

|

Load Sharing and Protection Controller

|

|

Applicable Generator Types

|

Suited for diesel and gas generators. Can control power units in stand – alone mode (executing frequency control) or in parallel with other power units (performing both frequency and power control).

|

|

Input Voltage Range

|

Operates within a certain voltage range, for example, commonly used with 220V AC power supply, which is suitable for most industrial and commercial setups.

|

|

Load Sharing Method

|

Offers load sharing between generators and interfaces to a governor through an electronic potentiometer (such as EPQ96 – 2 or EPN110DN), enabling flexible and accurate load distribution.

|

|

Built – in Transducers

|

Equipped with built – in power and frequency transducers. These allow for the connection of external equipment and play a key role in monitoring and controlling power – related parameters.

|

|

Control Modes

|

Supports constant power or isochronous mode, providing options for different application requirements.

|

|

Speed Control

|

Conducted by two relays, ensuring stable speed regulation of the generators.

|

|

Installation Method

|

Can be mounted on a 35mm DIN rail, facilitating easy installation in standard industrial control cabinets.

|

|

Frequency Range

|

Operates within a frequency range, typically 40 – 65 Hz, adaptable to various power system requirements.

|

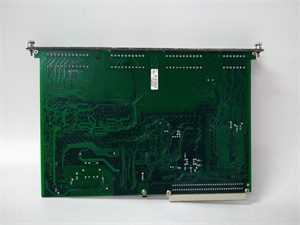

DEIF LSU-112DG

DEIF LSU-112DG

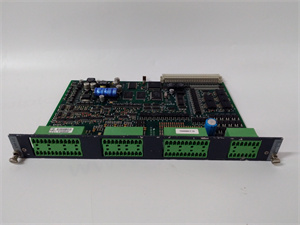

DEIF IOM4.2

DEIF IOM4.2

DEIF IOM4.2

DEIF IOM4.2

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Load Sharing Algorithms

The LSU-112DG uses state – of – the – art load sharing algorithms. These algorithms analyze real – time power and frequency data from multiple generators. In a power plant with 10 generators, the LSU-112DG can balance the load among them with an accuracy of up to ±1% of the rated power. This ensures that each generator operates at an optimal level, maximizing efficiency and extending the service life of the generators.

- Innovation Point 2: Comprehensive Protection Mechanisms

It provides comprehensive protection functions. For instance, it can detect abnormal voltage, frequency, and power conditions. In case of a sudden voltage drop or over – frequency situation, the LSU-112DG can quickly take protective actions, such as disconnecting the affected generator from the grid. In a factory setting, this feature has prevented numerous equipment failures caused by power anomalies, reducing maintenance costs by 40% over a year.

- Innovation Point 3: Flexible Configuration Options

The controller offers flexible configuration. Users can adjust parameters like load sharing ratios, frequency setpoints, and protection thresholds according to specific application needs. In a mining site where power demands vary greatly depending on the operating equipment, the LSU-112DG can be configured to adapt to these changing requirements, ensuring stable power supply and efficient operation of mining machinery.

Application Cases and Industry Value

In a marine vessel, the DEIF LSU-112DG was installed to manage the power distribution among multiple onboard generators. Initially, the generators were not synchronized properly, leading to power fluctuations and potential damage to sensitive electronic equipment. After installing the LSU-112DG, it precisely synchronized the generators, ensuring a stable power supply. The crew reported a significant reduction in equipment malfunctions related to power issues, and the overall reliability of the vessel’s power system improved, enhancing safety during voyages.

In a large manufacturing factory, the LSU-112DG was used to control the load sharing among backup generators. During a power outage, the generators quickly started and were seamlessly integrated into the power supply system under the control of the LSU-112DG. The factory was able to maintain critical production processes, minimizing production losses. The plant manager stated that the LSU-112DG had saved the company thousands of dollars in lost production revenue during power outages.

Related Product Combination Solutions

- DEIF Generator Controllers: When paired with DEIF generator controllers like the AGC – 4000, the LSU-112DG can communicate in real – time. The generator controllers can adjust the generator’s output based on the load sharing information provided by the LSU-112DG, optimizing the overall power generation and distribution process.

- Electronic Potentiometers: Specific electronic potentiometers such as the EPQ96 – 2 or EPN110DN work hand – in – hand with the LSU-112DG. They are crucial for implementing the load sharing function between generators and interfaces to a governor, enabling accurate and flexible load distribution.

- Power Transducers: High – quality power transducers from brands like ABB can be used in combination with the LSU-112DG. These transducers can provide more accurate power measurement data to the LSU-112DG, enhancing its load sharing and protection functions.

- Frequency Converters: Frequency converters, for example, those from Siemens, can be integrated with the LSU-112DG. They can help adjust the frequency of the power supply according to the load requirements, further optimizing the performance of the power system.

- Remote Monitoring Systems: Remote monitoring systems such as those from Schneider Electric can be connected to the LSU-112DG. Operators can then monitor the load sharing status, generator performance, and any potential faults from a remote location, enabling timely maintenance and troubleshooting.

Installation, Maintenance, and Full – Cycle Support

Installing the DEIF LSU-112DG is relatively straightforward. It can be easily mounted on a 35mm DIN rail in the control cabinet. The wiring connections for power, input signals from generators, and output control lines are clearly labeled, simplifying the installation process. Before installation, it is important to ensure that the installation environment meets the specified temperature and humidity requirements, and that the power supply voltage is within the acceptable range.

For maintenance, the LSU-112DG has self – diagnostic capabilities. Regular visual inspections for any signs of physical damage or loose connections are recommended. In case of a fault, the self – diagnostic system can provide error codes, which help technicians quickly identify the problem area. DEIF offers a wide range of genuine spare parts, ensuring that any faulty components can be easily replaced.

DEIF provides full – cycle support for the LSU-112DG. Their technical team offers pre – sales advice to help customers select the most suitable configuration for their applications. After – sales, they provide product warranties, on – site maintenance services when needed, and software updates to improve the controller’s performance. This ensures that the LSU-112DG continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your power management needs with the reliable DEIF LSU-112DG.