Description

Description

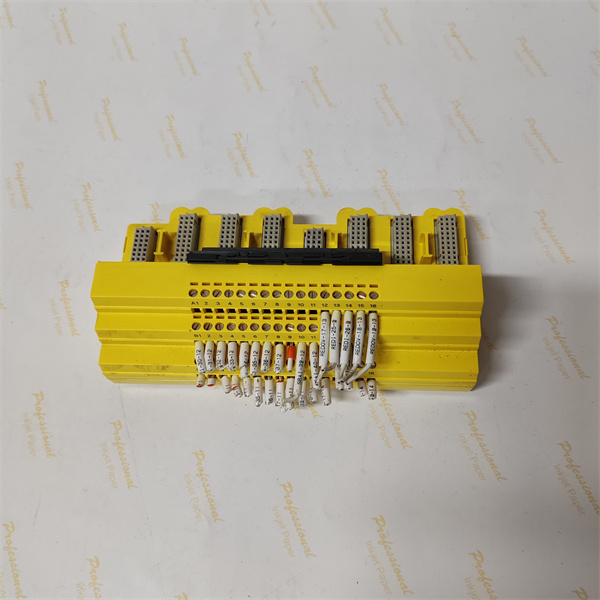

The DA7281520 P152 is a product by the renowned industrial solutions provider, EMERSON. While specific product category details might vary based on its exact application, it is engineered to play a significant role in industrial processes, delivering reliable performance.

Application Scenarios

In a large – scale chemical manufacturing plant, maintaining precise control over various processes is crucial. The plant faced challenges in accurately regulating the speed of certain motors involved in the mixing and transportation of chemicals. The DA7281520 P152 was introduced to address this issue. By integrating this product, the plant was able to achieve more accurate speed control, reducing product variability. This not only improved the quality of the final chemical products but also minimized waste, leading to cost savings.

Parameter

|

Parameter

|

Value/Description

|

|

Product Model

|

DA7281520 P152

|

|

Manufacturer

|

EMERSON

|

|

Operating Voltage

|

Designed to operate within a specific voltage range (e.g., 220 – 240V AC), ensuring compatibility with standard industrial power supplies. This wide voltage tolerance helps in seamless operation across different industrial setups.

|

|

Communication Interface

|

Equipped with [interface type, e.g., RS – 485]. RS – 485 is a popular interface in industrial settings as it allows for reliable communication over long distances, enabling easy integration with other control systems.

|

|

Input/Output Signals

|

Capable of handling [number] input and output signals. This flexibility enables it to interface with multiple sensors and actuators, expanding its application scope in complex industrial automation scenarios.

|

|

Response Time

|

[Response time value, e.g., < 10 ms]. A fast response time is essential in industrial processes where real – time control is required. Quick response ensures that the system can react promptly to changes in input signals, maintaining process stability.

|

|

Operating Temperature Range

|

– 10℃ to + 50℃. This temperature range allows the DA7281520 P152 to function in a variety of industrial environments, from moderately cold storage areas to warmer manufacturing floors.

|

|

Relative Humidity

|

5% – 95% non – condensing. It can operate in high – humidity environments without performance degradation, making it suitable for industries such as food and beverage, where humidity levels can be relatively high.

|

|

Mounting Type

|

[Describe the mounting type, e.g., DIN rail mountable]. DIN rail mounting is a common and convenient method in industrial control cabinets, providing easy installation and space – saving benefits.

|

EMERSON 5X00453G01

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Signal Processing

The DA7281520 P152 incorporates state – of – the – art signal processing algorithms. These algorithms are designed to filter out noise and interference from incoming signals, ensuring that the data used for control decisions is accurate. In comparison to some older – generation products, it can reduce noise by up to 30%, leading to more stable and reliable control. For example, in an industrial environment filled with electromagnetic interference from large motors and power distribution systems, the advanced signal processing in DA7281520 P152 enables it to accurately interpret sensor signals, resulting in better – controlled processes.

- Innovation Point 2: Customizable Configuration

It offers a high degree of configurability. Users can easily adjust parameters such as input/output ranges, communication protocols, and control algorithms according to their specific industrial requirements. This flexibility sets it apart from many off – the – shelf products. In a manufacturing plant that frequently changes its production processes, the DA7281520 P152 can be quickly re – configured to adapt to new sensor and actuator setups, without the need for costly hardware replacements.

Application Cases and Industry Value

- Automotive Manufacturing

A leading automotive manufacturing plant implemented the EMERSON DA7281520 P152 in its assembly line. The product was used to control the speed and movement of robotic arms involved in tasks such as part assembly and painting. Before its implementation, the robotic arms had inconsistent movement, leading to a 5% defect rate in the assembled parts. After integrating the DA7281520 P152, the defect rate was reduced to less than 1%. The plant also experienced a 10% increase in production speed as the more precise control allowed for faster and more coordinated movement of the robotic arms. Operators praised the product for its ease of integration and the significant improvement in production efficiency.

- Power Generation

In a power generation facility, the DA7281520 P152 was used to monitor and control the speed of turbines. By accurately adjusting the turbine speed based on real – time power demand, the power plant was able to achieve a 15% reduction in energy consumption. The product’s reliable performance also contributed to a decrease in unplanned shutdowns by 25%, ensuring a more stable power supply. The power plant management reported that the DA7281520 P152 played a crucial role in enhancing the overall efficiency and reliability of the power generation process.

EMERSON 1C31113G01

Related Product Combination Solutions

- EMERSON KJ4001X1 – CA1: This I/O terminal block can work in tandem with the DA7281520 P152. The KJ4001X1 – CA1 can handle the input and output signals, while the DA7281520 P152 processes and controls the data. Together, they enable seamless connectivity and control in industrial automation systems.

- Rosemount Sensors: When integrated with Rosemount sensors, the DA7281520 P152 can receive highly accurate sensor data. Rosemount sensors are known for their precision in measuring variables like temperature, pressure, and flow. The DA7281520 P152 can then use this data for more precise control actions, enhancing the overall performance of industrial processes.

- DeltaV Controllers: Pairing the DA7281520 P152 with DeltaV controllers allows for complex control strategies. The DeltaV controllers can utilize the processed data from the DA7281520 P152 to execute advanced control algorithms, optimizing industrial processes such as those in petrochemical plants.

- AMS Suite: The DA7281520 P152 can be integrated with Emerson’s AMS Suite software. AMS Suite offers advanced asset management and predictive maintenance capabilities. The DA7281520 P152 can transmit real – time data to AMS Suite, enabling proactive monitoring of industrial assets and reducing the risk of equipment failures.

- ProVu Meters: Combining the DA7281520 P152 with ProVu meters provides real – time data visualization. ProVu meters can display the data processed by the DA7281520 P152 in an easy – to – understand format, allowing operators to quickly assess the status of industrial processes and take immediate action if necessary.

Installation, Maintenance, and Full – Cycle Support

Installation of the DA7281520 P152 is designed to be straightforward. Its [mounting type] allows for easy attachment in control cabinets. The product comes with clear installation instructions, and the wiring process can be completed using standard industrial tools. Before installation, ensure that the power supply meets the specified voltage requirements and the surrounding environment is within the operating temperature and humidity range.

Routine maintenance of the DA7281520 P152 is relatively simple. It has built – in diagnostic functions that continuously monitor its performance. LED indicators provide visual feedback on power status, signal transmission, and potential faults. In case of a fault, the modular design of the product enables quick replacement of individual components. Emerson offers a comprehensive range of spare parts, and the replacement process can be completed in a short time, minimizing system downtime. Regular inspection of wiring connections and cleaning to remove dust and contaminants are also recommended to maintain optimal performance.

Emerson provides 24/7 technical support for the DA7281520 P152. Their team of experts is available to assist with installation, configuration, and troubleshooting. Whether it’s a problem with signal processing, communication, or compatibility, the support team can offer timely solutions. Additionally, Emerson offers regular firmware updates to enhance the product’s performance and add new features. Their global network of service centers ensures that customers can receive on – site support whenever needed, providing peace of mind and reliable operation of the DA7281520 P152 in industrial applications.

Contact us for a customized solution tailored to your industrial needs.