Description

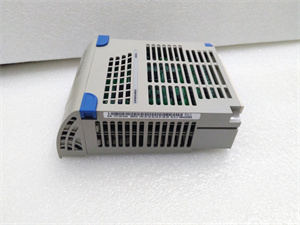

EMERSON FLOBOSS S600+

- •

Model Number: FLOBOSS S600+ - •

Manufacturer: Emerson - •

Product Type: Flow Computer / Flow Manager - •

Standards Supported: AGA 3, 7, 8, 9, 10; API MPMS Ch. 11.1, 12.2, 14.3; ISO 5167; and more. - •

Inputs: Analog (4-20mA), Pulse, Frequency, Discrete (Digital), RTD - •

Outputs: Analog (4-20mA), Discrete (Digital), Alarms - •

Communication Protocols: Modbus (RTU/TCP), OPC, ROC Plus, FloBoss EMS - •

Display: Backlit LCD with keypad for local interface - •

Power Supply: Typically 10.5 to 30 VDC or 85 to 265 VAC - •

Operating Temperature: -40°C to +70°C (-40°F to +158°F) - •

Hazardous Area Certifications: Class I, Division 2, Groups A, B, C, D; ATEX/IECEx - •

Enclosure: NEMA 4X (Weatherproof and Corrosion Resistant) EMERSON FLOBOSS S600+