Description

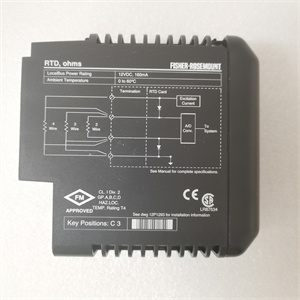

Emerson FX-316 960132-01

- •

Model Number: FX-316 - •

Manufacturer Part Number: 960132-01 - •

Manufacturer: Emerson (Foxboro) - •

Product Type: Vortex Flow Transmitter - •

Measurement Principle: Vortex Shedding - •

Output Signal: 4-20 mA HART (2-wire) - •

Power Supply: 12-42 VDC (standard loop power) - •

Accuracy: Typically ±1% of rate for liquids, ±1.5% for gas/steam - •

Turndown Ratio: Up to 10:1 - •

Process Connection: Flanged (e.g., ANSI, DIN, JIS) or Wafer-Style - •

Body Material: Carbon steel or stainless steel - •

Shedder Bar Material: Typically stainless steel - •

Sensor: Piezoelectric crystal - •

Pressure Rating: Varies with flange rating (e.g., ANSI 150, 300, 600) - •

Temperature Range: Standard: -40°C to +260°C (-40°F to +500°F); High-temp options available - •

Communications: HART protocol - •

Display: Optional local indicator