Description

EMERSON HD22010-3

- •

Model Number: HD22010-3 - •

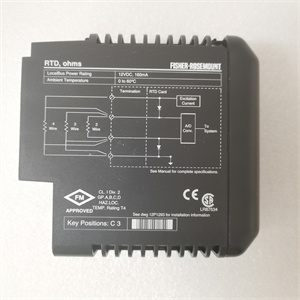

Manufacturer: Emerson (Rosemount) - •

Product Type: Pressure Transmitter - •

Pressure Type: Gauge Pressure (PSIG) - •

Pressure Ranges: Available in various ranges (e.g., 0-100 PSIG, 0-500 PSIG) - •

Output Signal: 2-Wire, 4-20 mA DC - •

Power Supply: 12-30 VDC (typical loop power) - •

Accuracy: Typically ±0.5% of span (including linearity, hysteresis, and repeatability) - •

Process Connection: 1/2″ NPT female or other standard - •

Electrical Connection: 1/2″ NPT conduit entry - •

Display: Optional local indicator (LCD or pointer gauge) - •

Wetted Parts: 316 Stainless Steel standard - •

Operating Temperature: -40°F to +185°F (-40°C to +85°C) - •

Process Temperature: Up to 250°F (121°C) - •

Safety Approvals: FM, CSA, ATEX, IECEx (for hazardous areas) EMERSON HD22010-3