Description

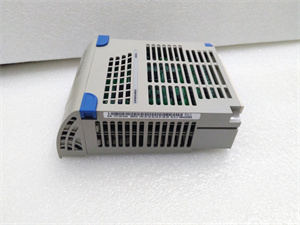

EMERSON KJ3225X1-BA1

- •

K300: Base product code for a V300 Vee-Ball valve. - •

S: Valve body series or specific design variant. - •

355: Valve size (e.g., 3-inch) and pressure class (e.g., ANSI Class 300). - •

N: Body material (e.g., Carbon Steel – WCB). - •

Z: Not specified in public documentation (often an internal code). - •

T: Trim material (e.g., 316 Stainless Steel). - •

116: Specific trim designation or characteristics. - •

A: Actuator type and size. - •

B: Additional actuator specifications (e.g., spring range). - •

P: Positioner type (e.g., Fisher FIELDVUE or other). - •

M: Additional accessories or modifiers. - •

AZZZ: Specific accessory package, likely including limit switches, solenoid valves, etc.

- •

Valve Size: Likely 3-inch - •

Pressure Class: Likely ANSI Class 300 - •

Body Material: Likely Carbon Steel (WCB) or Stainless Steel (CF8M) - •

Trim Material: Likely 316 Stainless Steel or hardened alloy - •

Actuator: Pneumatic, spring-return or double-acting - •

Positioner: Likely a digital positioner (e.g., Fisher FIELDVUE) - •

Accessories: May include limit switches, solenoid valves, air sets

- •

Controlling the flow of abrasive slurries in mining concentrators. - •

Regulating steam flow in power generation facilities. - •

Controlling the flow of stock containing wood fibers in pulp mills.