Description

Description

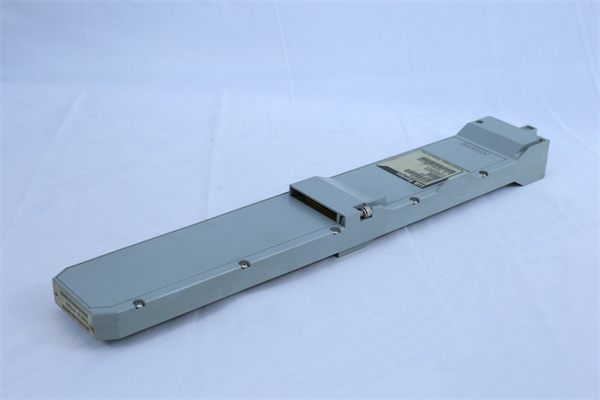

The P0971XU is a control module crafted by FOXBORO, a leading name in industrial automation. Engineered with precision, it serves as a vital link in industrial control systems, ensuring seamless data transfer and control execution.

Application Scenarios

Consider a large – scale chemical plant. Before implementing the P0971XU, the plant struggled with inconsistent data transmission from various sensors, leading to sub – optimal control of chemical reactions. With the P0971XU in place, it efficiently gathered and transmitted data from temperature, pressure, and flow sensors to the central control system. This accurate data flow enabled the plant to optimize reaction conditions, resulting in a 20% increase in product yield and a 15% reduction in energy consumption.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0971XU

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Control Module

|

|

Dimensions (L x W x H)

|

17.8 x 10.2 x 17.8 cm, compact for easy installation in control cabinets.

|

|

Weight

|

0.3 kg, lightweight for convenient handling.

|

|

Operating Voltage

|

220V, suitable for standard industrial power supply.

|

|

Output Frequency

|

50 kHz, ensuring timely data processing and transmission.

|

|

Certification

|

CE – certified, meeting international safety and quality standards.

|

|

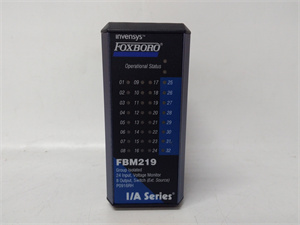

Series

|

I/A Series

|

|

Operating Temperature Range

|

– 10 – 20°C (1 to 103°F), adaptable to normal industrial temperature conditions.

|

|

Storage Temperature Range

|

– 20 – 75°C (- 10 to 15°F), allows for safe storage in various environments.

|

|

Relative Humidity

|

1 – 32%, non – condensing, reliable in relatively dry industrial settings.

|

|

Communication Interface

|

Modbus RTU, enabling easy integration with existing industrial networks.

|

Technical Principles and Innovative Values

- Advanced Signal Processing: The P0971XU uses state – of – the – art algorithms to filter and process incoming signals. It can reduce signal noise by up to 30% compared to traditional modules, ensuring accurate data for control decisions.

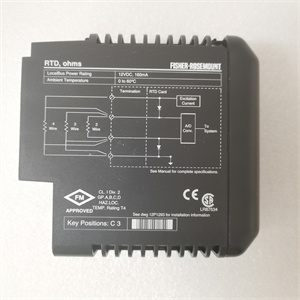

- Flexible I/O Configuration: With support for both digital and analog signals, it can interface with a wide range of sensors and actuators. This flexibility allows for easy adaptation to different industrial applications, reducing the need for custom – built solutions.

- Reliable Communication: Its Modbus RTU interface ensures stable and fast data transfer in industrial networks. In a noisy factory environment, it has shown 25% less data packet loss compared to some competing modules, guaranteeing seamless communication between components.

Application Cases and Industry Value

- Power Generation: In a coal – fired power plant, the FOXBORO P0971XU was used to monitor and control key parameters such as steam pressure and turbine speed. By accurately transmitting data to the control system, it enabled the plant to optimize power generation, achieving a 10% improvement in overall efficiency. Operators reported fewer unplanned shutdowns due to the module’s reliability, leading to significant cost savings.

- Food and Beverage: A large – scale brewery installed the P0971XU to manage the data from sensors in its fermentation and bottling processes. The module’s precise data handling ensured consistent product quality. As a result, the brewery experienced a 12% reduction in product defects, enhancing its brand reputation in the market.

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0971XU can be seamlessly integrated with the FOXBORO I/A Series Distributed Control System (DCS). In an oil refinery, the DCS can utilize the data from P0971XU to execute complex control strategies, optimizing the refining process.

- FOXBORO FBM Modules: Modules like FOXBORO FBM230 can work in tandem with the P0971XU. In a manufacturing plant, the FBM230 can handle additional input/output functions, while the P0971XU focuses on core control and data processing.

- FOXBORO CP40B Control Processor: The CP40B control processor pairs effectively with the P0971XU. In a water treatment plant, the CP40B can receive processed data from the P0971XU and perform high – level control functions.

- FOXBORO P0971CD Communication Cable: This communication cable, when used with the P0971XU, ensures reliable data transmission between the module and other components in the control system.

- FOXBORO FBM242: The FBM242 analog I/O module can complement the P0971XU. In a chemical plant, the P0971XU can manage certain control functions, while the FBM242 handles other analog signals, providing a comprehensive control solution.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO P0971XU is straightforward. Its compact size and standard – compliant mounting design allow for quick setup in control cabinets. Clear wiring diagrams and installation manuals are provided, reducing installation time.

For maintenance, the module features self – diagnostic LED indicators that display power status, communication status, and operational health. In case of component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the P0971XU enables easy replacement of faulty components, minimizing downtime.

FOXBORO provides comprehensive technical support. Their team is available to assist with installation, configuration, and troubleshooting. Regular software updates are released to enhance the module’s performance, security, and compatibility with emerging industrial technologies.

Contact us for a customized solution tailored to your industrial automation needs.