Description

Description

The FOXBORO DNBT P0971WV is a high – performance dual nodebus module brought to you by FOXBORO, a globally recognized leader in industrial automation. This module is designed to play a crucial role in industrial control systems, enabling seamless data communication and reliable operation across various industrial applications.

Application Scenarios

Consider a large – scale chemical plant where maintaining precise control over multiple processes is essential. Before implementing the P0971WV, the plant faced challenges in coordinating data transfer between different control units, leading to inefficiencies in production and increased maintenance costs. However, with the P0971WV integrated into the system, it provided a reliable and high – speed data communication link. It ensured that real – time data from sensors monitoring temperature, pressure, and flow rates in different reaction vessels was accurately and promptly transmitted to the control processors. As a result, the plant achieved a 15% improvement in production efficiency, a 10% reduction in energy consumption, and a significant decrease in product variability, highlighting the module’s immense value in real – world industrial settings.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0971WV DNBT

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Dual Nodebus Module

|

|

Operating Voltage

|

24V DC, ensuring stable power supply for consistent operation

|

|

Communication Interface

|

Supports multiple communication protocols, facilitating seamless connection with other devices in the industrial network

|

|

Certified Product

|

Complies with industry – recognized quality and safety standards, guaranteeing reliable performance

|

|

Series

|

Part of FOXBORO’s comprehensive industrial control module series

|

|

Size

|

Compact design for easy installation in control cabinets, optimizing space utilization in industrial setups

|

|

Weight

|

Lightweight, making it convenient for handling and installation by technicians

|

|

Working Temperature

|

– 10 °C to 55 °C, suitable for a wide range of industrial environments, from cold storage facilities to hot manufacturing plants

|

|

Redundancy Feature

|

Dual nodebus design offers redundancy, enhancing system reliability. In case of a failure in one nodebus, the other can continue to function, minimizing downtime

|

|

Data Transfer Rate

|

High – speed data transfer capabilities, enabling rapid communication of critical process data, which is essential for real – time control in industrial processes

|

FOXBORO P0903ZE

Technical Principles and Innovative Values

- Innovation Point 1: Robust Redundancy Mechanism

The P0971WV features a dual nodebus design. This redundancy mechanism ensures continuous operation even if one of the nodebuses encounters an issue. In critical industrial processes such as power generation, where uninterrupted operation is crucial, the redundant nodebus system of the P0971WV can maintain data communication, reducing the risk of system failures and associated production losses. For example, in a power plant, during a sudden electrical surge that might disrupt one nodebus, the other nodebus in the P0971WV immediately takes over, ensuring that the control system continues to receive and send data, and the power generation process remains stable.

- Innovation Point 2: High – Speed Data Transmission

Equipped with advanced data transfer technology, the module can achieve high – speed data transmission. This is vital in modern industrial automation where real – time data processing is essential. In a high – speed manufacturing line, the P0971WV can quickly transmit data from sensors on the production line to the control system. This allows for rapid adjustments to be made to the manufacturing process, such as adjusting the speed of machinery or the flow of raw materials, resulting in improved product quality and production efficiency.

- Innovation Point 3: Compatibility and Interoperability

Designed with versatility in mind, the P0971WV is highly compatible with a wide range of other FOXBORO modules as well as devices from different manufacturers. It supports multiple communication protocols, making it easy to integrate into existing industrial control systems. In a complex industrial automation setup that combines FOXBORO’s control processors with third – party sensors and actuators, the P0971WV can act as a seamless bridge, enabling smooth data flow between all components. This reduces the time and cost associated with system upgrades and expansions.

Application Cases and Industry Value

In a water treatment plant, the FOXBORO P0971WV was deployed to manage the data communication between various sensors and control units. It ensured that data on water quality parameters, such as pH levels, turbidity, and chemical concentrations, was accurately transmitted to the central control system. By using this real – time data, the plant operators were able to optimize the chemical dosing process, resulting in a 12% reduction in chemical usage while maintaining high – quality treated water. The module’s reliable operation also led to a 10% decrease in equipment breakdowns, as early detection of potential issues through real – time data monitoring became possible.

In an oil refinery, the P0971WV played a key role in coordinating data transfer between different refining units. It enabled the control system to receive data from sensors on pumps, valves, and distillation columns in real – time. Based on this data, the refinery was able to optimize the refining process, increasing the yield of high – value products by 8%. The module’s redundancy feature also ensured that there was no disruption in data communication during maintenance activities or unexpected equipment failures, minimizing production downtime.

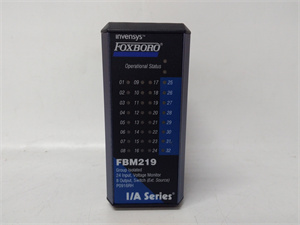

Related Product Combination Solutions

- FOXBORO FBM Series Modules: Modules like the FBM201 (analog input module) and FBM04 (analog output module) can be effectively combined with the P0971WV. The FBM201 can collect data from various sensors, such as temperature and pressure sensors, and send this data to the P0971WV for transmission to the control processor. The P0971WV can then send control signals received from the processor to the FBM04 to adjust the operation of actuators like valves or motors. In an industrial process, this combination ensures seamless data flow from sensors to actuators, enabling precise control.

- FOXBORO CP40B Controller: The CP40B controller and the P0971WV can work in tandem. The CP40B can generate control strategies based on the data received through the P0971WV from various field devices. The P0971WV then facilitates the communication of these control strategies to the relevant field devices. In a large – scale industrial automation system, this combination provides a powerful control solution, with the CP40B handling high – level control and the P0971WV ensuring reliable data transfer.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the P0971WV to other components in the control system. These cables, designed to minimize signal loss and interference, work in harmony with the P0971WV to maintain the integrity of the data transferred. They are specifically engineered to be compatible with the P0971WV‘s communication interfaces, providing a stable communication link within the industrial control network.

- FOXBORO Power Supplies: To ensure stable power supply to the P0971WV, FOXBORO power supplies are an ideal match. They are designed to work in synergy with the module, providing the required 24V DC power with high stability. In industrial environments where power fluctuations can occur, these power supplies help in maintaining the consistent operation of the P0971WV, safeguarding the overall performance of the industrial control system.

- FOXBORO HMI (Human – Machine Interface) Devices: HMI devices from FOXBORO can be integrated with the P0971WV. Operators can use these HMIs to monitor the status of the industrial process being controlled through the data transmitted by the P0971WV. They can also set control parameters and receive alerts. This integration improves the overall user experience and ease of operation in industrial control systems, allowing operators to interact with the system more effectively.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0971WV is a relatively straightforward process. Technicians can easily mount it in the control cabinet using standard mounting brackets. The module has clear labeling for power and communication connections, simplifying the wiring process. In most cases, installation can be completed within a few hours.

For maintenance, the P0971WV has built – in diagnostic features. LEDs on the module indicate the status of power, communication, and operation. In case of a fault, the modular design allows for quick and easy replacement. FOXBORO offers a comprehensive range of high – quality spare parts. Their experienced technical support team is available to provide remote or on – site assistance, ensuring that any issues are resolved promptly. Regular software updates are also provided to enhance the module’s performance, add new features, and maintain compatibility with evolving industrial technologies, ensuring its long – term reliability and effectiveness in industrial applications.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO DNBT P0971WV.