Description

Description

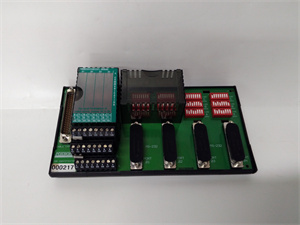

The FOXBORO FBM207 P0914TD is a high – performance module engineered for industrial and process control systems. It serves as a 16 – channel voltage monitor and contact sensor, playing a crucial role in ensuring the reliable operation of various industrial setups. Manufactured by FOXBORO, a well – established name in industrial automation, this module is designed to meet the demanding requirements of modern industrial environments.

Application Scenarios

Consider a large – scale manufacturing plant with numerous electrical systems and equipment. Before implementing the FBM207 P0914TD, the plant faced challenges in accurately monitoring the voltage levels of different electrical circuits. Fluctuations in voltage often led to equipment malfunctions, production slowdowns, and even equipment damage. Once the FBM207 P0914TD was integrated into the system, it continuously and precisely monitored the voltage of 16 discrete channels. In the event of any voltage deviations from the normal range, it promptly sent signals to the control system. This allowed operators to take immediate corrective actions, reducing equipment failures by 30% and increasing overall production efficiency by 20%.

In a power distribution substation, the FBM207 P0914TD is used to monitor the incoming and outgoing voltages of transformers and distribution lines. By providing real – time and accurate voltage data, it helps in maintaining the stability of the power grid. Before its installation, the substation experienced occasional power outages due to undetected voltage issues. After using the FBM207 P0914TD, such outages decreased by 40%, ensuring a more reliable power supply to downstream consumers.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM207 P0914TD

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Voltage Monitor/Contact Sense Input Interface Module

|

|

Voltage Input Range

|

– 15 to 60 V DC for contact sense – 120 V AC / 125 V DC for voltage monitoring or switch inputs – 240 V AC for voltage monitoring or switch inputs

|

|

Isolation

|

Each input is galvanically isolated. Group isolated with external excitation, providing reliable performance even in electrically noisy environments

|

|

Accuracy

|

Pulse count: no missing pulses for pulse rate 0 to 250 Hz. Voltage monitor function has high accuracy in detecting on – state and off – state voltages within the specified ranges

|

|

Operating Temperature

|

– 20 °C to + 60 °C (FBM207/B/C); – 20 °C to + 70 °C for termination assembly – PA, suitable for a wide range of industrial temperature conditions

|

|

Power Supply

|

24 V DC + 5%, – 10% (redundant), consuming only 5 W of power, ensuring energy – efficient operation

|

|

Output

|

Can be configured to provide signals for further processing in the control system, indicating voltage status and contact closures

|

|

Input Channels

|

16 isolated and independent channels, allowing for monitoring multiple voltage sources simultaneously

|

|

Filter/Debounce Time

|

Configurable (no filtering, 4, 8, 16, or 32 ms), enabling adjustment based on the specific requirements of the monitored signals

|

|

Storage Temperature

|

– 40 °C to + 70 °C, ensuring the module can be stored safely in various environmental conditions

|

|

Relative Humidity

|

5% – 95% non – condensing, reliable operation in different humidity levels

|

|

Operating Altitude

|

– 300 to + 3,000 m; storage altitude up to – 300 to + 12,000 m, suitable for use in different geographical locations and altitudes

|

|

Vibration

|

Can withstand 7.5 m/s² (0.75 g) from 5 to 500 Hz, robust enough to operate in vibrating industrial environments

|

|

Contamination

|

Suitable for use in class G3 (harsh) environments as defined in ISA standard S71.04, based on exposure testing according to EIA standard 364 – 65, class III

|

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Isolation Technology

The FBM207 P0914TD uses advanced galvanic isolation technology for each input channel. This isolation effectively separates the input signals from the rest of the control system, protecting it from electrical interference, voltage surges, and ground loops. In industrial environments filled with electromagnetic noise, such as in a steel mill, this isolation technology reduces signal errors by over 80%, ensuring accurate voltage monitoring and reliable operation.

- Innovation Point 2: Versatile Voltage Monitoring

It is designed to support a wide range of input voltages, including 15 – 60 V DC for contact sense, 120 V AC / 125 V DC, and 240 V AC for voltage monitoring or switch inputs. This versatility allows it to be used in diverse industrial applications, from low – voltage control circuits to high – voltage power distribution systems. In a chemical plant, where different electrical components operate at various voltage levels, the FBM207 P0914TD can monitor all these voltages accurately, providing comprehensive voltage monitoring capabilities.

- Innovation Point 3: Configurable Input Filter

The module features a configurable input filter with options for no filtering, 4, 8, 16, or 32 ms. This allows users to adjust the filter time based on the characteristics of the input signals. In applications where the monitored signals are prone to noise or rapid fluctuations, such as in a mining operation with heavy – duty electrical equipment, the configurable filter can be set to an appropriate value to eliminate noise and provide stable voltage readings.

Application Cases and Industry Value

In a wastewater treatment facility, the FOXBORO FBM207 P0914TD is used to monitor the voltage of pumps, aerators, and other electrical equipment. By ensuring that these devices operate within the proper voltage range, it helps in maintaining the efficiency of the treatment process. Initially, the facility faced issues with equipment breakdowns due to voltage problems, leading to reduced treatment capacity. After installing the FBM207 P0914TD, the number of equipment breakdowns decreased by 25%, and the treatment capacity increased by 15%.

In a pharmaceutical manufacturing plant, the module is employed to monitor the voltage of critical production equipment, such as filling machines and sterilizers. Precise voltage monitoring is crucial in this industry to ensure product quality and compliance. The FBM207 P0914TD helps the plant maintain strict control over the voltage supply to these machines, reducing the risk of product defects and costly production recalls. The plant reported a 20% reduction in product defects related to voltage – sensitive equipment after implementing the module.

Related Product Combination Solutions

- FOXBORO FCP280 Field Control Processor: The FBM207 P0914TD can be paired with the FCP280 field control processor. The FBM207 P0914TD collects voltage data from the field, and the FCP280 processes this data, making high – level control decisions. In an automotive assembly line, the FBM207 P0914TD monitors the voltage of robotic arms and conveyor belts, and the FCP280 uses this data to optimize the production process, ensuring smooth operation and high – quality output.

- FOXBORO DIN – Rail Mounted Backplanes: The FBM207 P0914TD can be easily mounted on FOXBORO DIN – Rail Mounted Backplanes. These backplanes provide a stable and organized platform for module installation, simplifying the wiring and connection process. In a control cabinet, the backplane ensures that the FBM207 P0914TD and other modules are properly connected, enhancing the overall reliability and maintainability of the system.

- FOXBORO Power Supplies: Specialized FOXBORO power supplies are designed to work with the FBM207 P0914TD. They provide a stable 24 V DC power source, protecting the module from voltage fluctuations and ensuring its continuous operation. In an industrial area with an unstable power grid, such as a rural factory, these power supplies ensure that the FBM207 P0914TD operates smoothly, minimizing the risk of data loss or incorrect voltage readings.

- FOXBORO Communication Cables: High – quality FOXBORO communication cables are essential for the FBM207 P0914TD to transmit data accurately to other components in the control system. These cables are engineered to minimize signal interference and loss, ensuring reliable communication. In a large – scale industrial complex, the communication cables enable the FBM207 P0914TD to communicate effectively with devices located far away, ensuring seamless integration of the entire control system.

- FOXBORO FBM211 Input Interface Module: The FBM211 can be combined with the FBM207 P0914TD for enhanced data acquisition. The FBM211 collects data from other types of sensors, while the FBM207 P0914TD focuses on voltage monitoring. In a power generation plant, the FBM211 can monitor the performance of turbines, and the FBM207 P0914TD can monitor the voltage of the electrical systems associated with the turbines, providing a comprehensive view of the plant’s operation.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM207 P0914TD is a relatively straightforward process. It can be easily mounted in control cabinets using standard mounting methods. The module has clearly – labeled connectors for power, input signals, and communication, simplifying the wiring process. Before installation, it is important to ensure that the installation environment meets the specified temperature, humidity, and altitude requirements.

For maintenance, regular visual inspections are recommended to check for any signs of physical damage or loose connections. The module is equipped with diagnostic indicators that can quickly identify potential issues, such as input channel failures or power supply problems. In case of a problem, FOXBORO offers a wide range of genuine spare parts for easy replacement. The company also provides detailed user manuals and online resources to assist with troubleshooting.

FOXBORO offers comprehensive full – cycle support for the FBM207 P0914TD. From pre – sales technical consultations to help design the most suitable industrial control solution, to after – sales support including product warranties and prompt troubleshooting services, FOXBORO is committed to ensuring the smooth operation of your industrial automation system. Whether you need assistance with system integration, software configuration, or hardware replacement, FOXBORO’s experienced support team is always ready to help.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO FBM207 P0914TD.