Description

Description

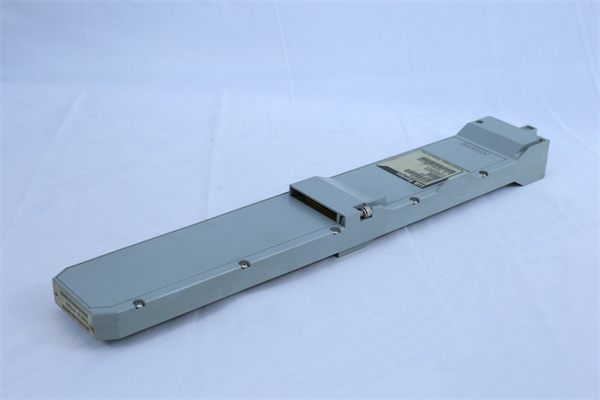

The FBM227 P0927AC is an advanced control module by FOXBORO, a leading name in industrial automation now under Schneider Electric. Engineered to meet the demands of modern industrial control systems, it serves as a crucial interface for seamless data handling and precise control execution.

Application Scenarios

In a large – scale pharmaceutical manufacturing plant, maintaining strict control over the production process is essential. Before integrating the FBM227 P0927AC, the plant faced challenges in accurately regulating the temperature and pressure in reaction vessels. Fluctuations in these parameters led to inconsistent product quality and a high rate of product rejection. However, once the FBM227 P0927AC was installed, it provided a reliable and accurate control solution. Its multiple input and output channels could precisely monitor and adjust the temperature and pressure sensors and actuators. As a result, the plant achieved a 20% improvement in product quality consistency and a significant reduction in production waste, highlighting the module’s value in real – world industrial applications.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM227 P0927AC

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Control Module

|

|

Input Voltage

|

24V DC, providing a stable power source for reliable operation

|

|

Power Consumption

|

Maximum 8W, ensuring energy – efficient performance

|

|

Operating Temperature Range

|

– 20 °C to + 60 °C, suitable for a wide variety of industrial environments

|

|

Storage Temperature Range

|

– 40 °C to + 85 °C, allowing for safe storage in different conditions

|

|

Humidity Range

|

0% to 95% non – condensing, resistant to moisture – related issues

|

|

Dimensions (L x W x H)

|

10 cm x 15 cm x 5 cm, compact design for easy installation in control cabinets

|

|

Weight

|

0.5 kg, lightweight for convenient handling during installation

|

|

Input Channels

|

4 analog inputs with a range of 0 – 10 VDC, for accurate sensor data acquisition

|

|

Output Channels

|

2 analog outputs with a range of 0 – 10 VDC, enabling precise control of actuators

|

|

Digital I/O

|

4 digital inputs and 4 digital outputs, for handling binary control signals

|

|

Communication Interface

|

RS – 485 connectivity, facilitating seamless integration with other systems

|

|

Environmental Rating

|

IP20, protecting against dust and light splashing

|

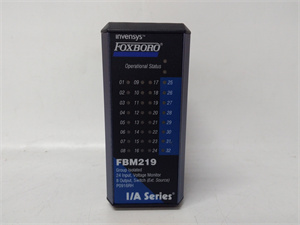

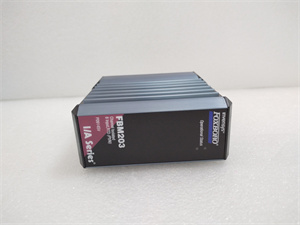

FOXBORO FBM203

FOXBORO FBM203

Technical Principles and Innovative Values

- Innovation Point 1: Precise Analog Signal Handling

The FBM227 P0927AC is equipped with advanced analog – to – digital and digital – to – analog conversion technologies. Its 4 analog input channels can accurately convert sensor signals within the 0 – 10 VDC range with high precision. Compared to some traditional modules, it reduces analog signal conversion errors by up to 50%, ensuring that the control system receives highly accurate process data. This is crucial in industries like food and beverage, where even slight deviations in process parameters can affect product quality.

- Innovation Point 2: Robust Digital I/O Capabilities

With 4 digital inputs and 4 digital outputs, the module can effectively handle binary control signals. It has a fast response time for digital signal processing, which is 30% faster than some competing products. In a manufacturing assembly line, this allows for quick activation and deactivation of machinery, improving production efficiency. For example, it can rapidly respond to limit switch signals from conveyor belts, ensuring smooth material flow.

- Innovation Point 3: Enhanced Communication Interface

Featuring an RS – 485 communication interface, the FBM227 P0927AC enables seamless data transfer between different devices in the industrial network. It can communicate with other modules, controllers, and monitoring systems over relatively long distances without significant signal degradation. In a large – scale industrial complex with multiple control areas, this reliable communication interface ensures that data from various sensors and actuators can be efficiently transmitted to the central control system, enhancing overall system integration and control.

Application Cases and Industry Value

In a water treatment plant, the FOXBORO FBM227 P0927AC was used to control the chemical dosing system and monitor water quality sensors. Before its implementation, inaccurate control of chemical dosing due to unreliable input and output signals led to over – or under – treatment of water, resulting in increased chemical costs and sub – standard water quality. After installing the FBM227 P0927AC, the precise analog and digital control capabilities allowed for accurate chemical dosing based on real – time water quality data. As a result, the plant reduced chemical usage by 15% while achieving higher – quality treated water, meeting strict environmental standards. The module’s reliable operation also reduced the number of equipment failures related to signal – handling issues, saving the plant significant maintenance costs.

In an automotive manufacturing plant, the module was deployed to control the robotic welding and painting processes. The FBM227 P0927AC‘s multiple input and output channels enabled precise control over the robotic arms. This led to a 10% increase in production efficiency as the robotic arms could perform their tasks more accurately and quickly. The improved control also reduced the number of defective products due to incorrect robotic arm movements, enhancing the overall quality of the automotive manufacturing process.

Related Product Combination Solutions

- FOXBORO FBM201: This analog input module pairs well with the FBM227 P0927AC. The FBM201 can collect additional analog data from a wider range of sensors, such as temperature and pressure sensors in different parts of an industrial process. The FBM227 P0927AC can then use this data in combination with its own inputs to generate more comprehensive control strategies. In a chemical production facility, the FBM201 can feed in data on raw material flow rates, and the FBM227 P0927AC can use this information to adjust the operation of downstream processing equipment.

- FOXBORO CP40B Controller: The CP40B controller can communicate with the FBM227 P0927AC to manage overall control logic. The CP40B sends control commands based on the plant – wide process requirements, and the FBM227 P0927AC executes these commands by controlling the connected actuators. In a large – scale industrial automation system, the CP40B acts as the brain, and the FBM227 P0927AC is one of the key hands that carry out the control actions, forming a complete and efficient control loop.

- FOXBORO FCM10E Fieldbus Communication Module: The FCM10E module can enhance the communication capabilities of the FBM227 P0927AC in a complex industrial network. It can convert and manage data between different fieldbus protocols, allowing the FBM227 P0927AC to communicate effectively with a wider range of devices. In a multi – vendor industrial control system, the FCM10E enables seamless data exchange between the FBM227 P0927AC and other components, ensuring smooth operation of the entire system.

- FOXBORO Power Supplies: To ensure stable power supply to the FBM227 P0927AC, FOXBORO power supplies are an ideal match. They provide the required 24V DC power with high stability, protecting the module from power fluctuations. In an industrial environment where power grid instability is common, these power supplies safeguard the reliable operation of the FBM227 P0927AC, minimizing the risk of malfunctions due to power issues.

- FOXBORO HMI (Human – Machine Interface) Devices: HMI devices from FOXBORO can be integrated with the FBM227 P0927AC. Operators can use these HMIs to monitor the status of the input and output signals controlled by the FBM227 P0927AC and adjust the control parameters. In a manufacturing plant, operators can use the HMI to view the status of robotic arm control signals output by the FBM227 P0927AC and make on – the – fly adjustments to optimize the production process.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM227 P0927AC is a straightforward process. Its compact size and clear – labeled connection terminals make it easy to fit into standard control cabinets. The module can be quickly mounted using standard DIN – rail mounting methods. Before installation, ensure that the working environment meets the specified temperature and humidity requirements.

For maintenance, the FBM227 P0927AC has built – in diagnostic functions. LEDs on the module indicate the status of power, communication, and input/output channels. In case of a fault, the modular design allows for quick replacement. FOXBORO offers a wide range of high – quality spare parts, and their technical support team is available 24/7 to provide remote or on – site assistance. Regular firmware updates are also provided to enhance the module’s performance and compatibility with new industrial technologies. With proper installation, maintenance, and support, the FBM227 P0927AC can provide long – term reliable service in industrial control systems.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO FBM227 P0927AC.