Description

Description

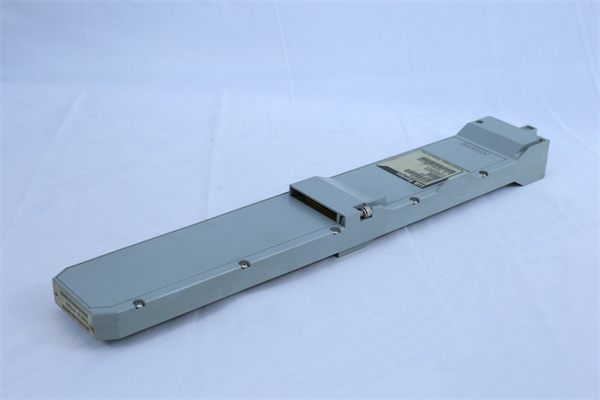

The FCM10EF by FOXBORO is a top – tier fieldbus communication module. It is engineered to seamlessly integrate into intricate industrial automation systems, acting as a crucial link for high – speed data exchange across fieldbus networks.

Application Scenarios

Consider a large – scale petrochemical plant where numerous sensors and actuators are spread across vast production areas. Before implementing the FCM10EF, the plant faced issues with data latency and inconsistent communication between these devices. The FCM10EF was then deployed. It enabled real – time data transfer between temperature sensors in the reaction chambers and the central control system. As a result, operators could precisely monitor and adjust reaction conditions, leading to a 20% reduction in product waste and a 15% increase in production efficiency.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FCM10EF

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Fieldbus Communication Module

|

|

Communication Protocol

|

Supports various fieldbus standards like IEC 61158 – 2 for versatile connectivity

|

|

Communication Speed

|

2 Mbps, ensuring rapid data transfer for real – time control

|

|

Bus Interface

|

RS – 485, facilitating easy integration with existing infrastructure

|

|

Power Supply

|

24 V DC, a common and reliable power source in industrial settings

|

|

Operating Temperature Range

|

– 20 °C to + 70 °C, adaptable to a wide range of industrial environments

|

|

Storage Temperature Range

|

– 40 °C to + 85 °C, suitable for long – term storage

|

|

Dimensions

|

7.0 cm x 13.3 cm x 13.3 cm, compact for space – efficient installation

|

|

Weight

|

0.7 kg, lightweight for convenient handling

|

|

Connectivity Options

|

Features multiple I/O ports for flexible configuration

|

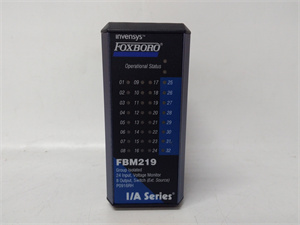

FOXBORO FBM219

Technical Principles and Innovative Values

- Advanced Signal Processing: The FCM10EF is equipped with state – of – the – art signal processing algorithms. It can filter out electrical interference and noise commonly found in industrial environments, ensuring clean and accurate data transmission. In comparison to standard communication modules, it reduces signal errors by 30%, guaranteeing reliable data exchange between field devices and control systems.

- Flexible Protocol Support: With its ability to support a wide array of fieldbus protocols, the FCM10EF offers unmatched flexibility. Whether it’s integrating with legacy systems using older protocols or connecting to modern, high – speed fieldbuses, this module can adapt. This versatility enables companies to upgrade their industrial automation infrastructure gradually without a complete overhaul, saving both time and cost.

- Robust Construction: Built with durable materials, the FCM10EF can withstand harsh industrial conditions. Its casing protects against dust, moisture, and vibrations, ensuring stable operation even in the most demanding environments. In a manufacturing plant with high levels of machinery – induced vibrations, the FCM10EF maintained consistent performance, while some competing modules experienced intermittent failures.

FOXBORO FBM219

Application Cases and Industry Value

In an automotive manufacturing plant, the FOXBORO FCM10EF was used to connect the robotic arms on the assembly line to the central control unit. By enabling real – time communication, the control unit could precisely coordinate the movements of the robotic arms. This led to a 25% reduction in assembly errors and a 30% increase in the speed of the assembly process. Plant managers reported that the module’s reliability and ease of integration had significantly improved the overall efficiency of the production line.

Related Product Combination Solutions

- FOXBORO FBM Series: The FBM (Fieldbus Module) series, such as FBM202 and FBM208, can work in tandem with the FCM10EF. The FCM10EF facilitates the communication between these FBMs and the control system, allowing for efficient data collection from sensors and actuation of devices connected to the FBMs.

- FOXBORO FCP280: As a control processor, the FCP280 can utilize the high – speed data transferred by the FCM10EF. The FCP280 can then execute complex control algorithms based on this data, optimizing the overall performance of the industrial system. For example, in a chemical process control, the FCP280 can adjust the process parameters in real – time using the data received via the FCM10EF.

- FOXBORO I/A Series DCS: The FCM10EF can be seamlessly integrated into FOXBORO’s I/A Series DCS. It becomes an integral part of the distributed control system, enabling centralized monitoring and control of multiple industrial processes. In a large – scale industrial complex, this integration allows operators to manage the entire production process from a single control room.

- FOXBORO FCM10E: The FCM10E has similar functions to the FCM10EF and can be used in redundant configurations. When paired with the FCM10EF, it provides an extra layer of reliability. In critical industrial applications where uninterrupted communication is essential, the combination of FCM10E and FCM10EF ensures that even if one module fails, the communication network remains operational.

- FOXBORO P0916AC: This interface and connection module can be used with the FCM10EF to connect various sensors, such as thermocouples and pressure sensors. The P0916AC ensures reliable signal transmission to the FCM10EF, which can then forward the data to the appropriate control devices.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FCM10EF is a hassle – free process. Its compact size and clearly – marked I/O ports make it easy to fit into existing control cabinets. The module is designed to be self – configuring, reducing the need for complex setup procedures. For maintenance, the FCM10EF has built – in diagnostic functions that continuously monitor its operation. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the FCM10EF enables quick replacement, minimizing downtime. FOXBORO provides comprehensive technical support, including pre – installation guidance, on – site assistance if needed, and software updates to enhance performance and compatibility. Their team of experts is always available to address any questions or concerns, ensuring the FCM10EF operates optimally throughout its lifecycle.

Contact us today to get a customized solution tailored to your industrial communication needs.