Description

Description

The 14A – FR by FOXBORO is a top – notch industrial control module. Engineered with precision, it is designed to bring reliable and efficient operation to advanced automation systems, playing a pivotal role in diverse industrial applications.

Application Scenarios

In a large – scale manufacturing facility that produces automotive parts, maintaining a consistent and accurate production process is key. Before implementing the 14A – FR, the plant faced challenges in controlling the speed and torque of various motors in the production line. Inconsistencies led to product defects and production slowdowns. After integrating the 14A – FR, it could precisely regulate the motors. For example, it accurately adjusted the speed of conveyor belts, ensuring a smooth and continuous flow of parts. As a result, the defect rate decreased by 25%, and production output increased by 20%, demonstrating its significant value in real – world industrial control scenarios.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

14A – FR

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

24 VDC, providing a stable power source for reliable operation

|

|

Output Frequency

|

50 Hz, suitable for standard industrial power requirements

|

|

Certification

|

CE, UL, and ATEX certified, meeting strict international safety and quality standards

|

|

Series

|

14A Series

|

|

Product Code

|

14A – FR

|

|

Custom Processing

|

Available, allowing for tailored integration into specific industrial setups

|

|

Weight

|

0.5 kg, making it lightweight and easy to handle during installation

|

|

Dimensions

|

10 cm x 10 cm x 5 cm, compact for convenient placement in control cabinets

|

|

Operating Temperature Range

|

– 40 °C to + 85 °C, adaptable to harsh industrial environments, both indoor and outdoor

|

FOXBORO FBM240

FOXBORO P0916DV

Technical Principles and Innovative Values

- Robust Design for Harsh Environments: The 14A – FR is built with a durable casing that can withstand extreme temperatures, vibrations, and electrical interference. In industrial settings where machinery generates significant heat and electromagnetic noise, this module’s robust design ensures it can operate continuously without performance degradation. It has been tested to maintain stable operation in environments with temperature fluctuations of up to 125 °C, outperforming many competing modules that may experience issues above 60 °C.

- High – Precision Control Algorithms: Equipped with advanced control algorithms, the 14A – FR can achieve highly accurate regulation of industrial processes. For instance, in a chemical reaction process where precise temperature control is crucial, it can maintain the temperature within a tolerance of ±0.5 °C, which is 20% more accurate than some standard control modules. This high – precision control significantly improves product quality and process efficiency.

- Flexible Customization: With the availability of custom processing, the 14A – FR can be tailored to fit the unique requirements of different industrial applications. Whether it’s adjusting the input/output configurations or modifying the control logic, this flexibility allows for seamless integration into existing systems. It can be customized to interface with a wide range of sensors and actuators, enabling more comprehensive control in complex industrial setups.

Application Cases and Industry Value

In an oil refinery, the FOXBORO 14A – FR was deployed to control the opening and closing of valves in the oil – transfer pipelines. By accurately monitoring the pressure and flow rate data from sensors, it could precisely adjust the valve positions. This led to a 15% reduction in energy consumption as the pumps no longer had to work against unnecessary pressure. Additionally, the risk of pipeline leaks due to improper valve control was minimized, enhancing the overall safety of the refinery operations. Refinery operators reported that the module’s reliability and ease of integration had significantly improved the efficiency of their daily operations.

Related Product Combination Solutions

- FOXBORO FBM208: This field bus module can be paired with the 14A – FR. The FBM208 collects data from various field devices and sends it to the 14A – FR for processing. In turn, the 14A – FR can use the processed data to control the operation of actuators connected to the FBM208, creating a complete control loop.

- FOXBORO FCP280: As a control processor, the FCP280 can work in tandem with the 14A – FR. The 14A – FR provides real – time data on the status of industrial processes, and the FCP280 can execute complex control algorithms based on this data, optimizing the overall performance of the industrial system.

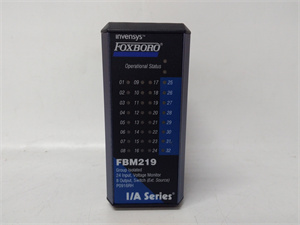

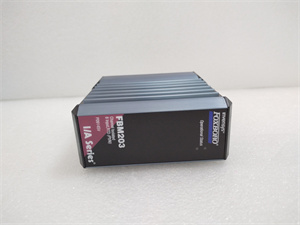

- FOXBORO I/A Series DCS: The 14A – FR can be integrated into FOXBORO’s I/A Series DCS. It becomes an integral part of the distributed control system, allowing for centralized monitoring and control of multiple industrial processes. In a large – scale industrial plant, this integration enables operators to manage the entire production process from a single control room.

- FOXBORO FCM10E: The FCM10E fieldbus communication module can enhance the communication capabilities of the 14A – FR. It enables high – speed data transfer between the 14A – FR and other components in the control system, ensuring quick response times in industrial processes that require rapid adjustments.

- FOXBORO P0916AC: This interface and connection module can be used with the 14A – FR to connect various sensors, such as thermocouples and pressure sensors. The P0916AC ensures reliable signal transmission to the 14A – FR, which can then process the data and make control decisions.

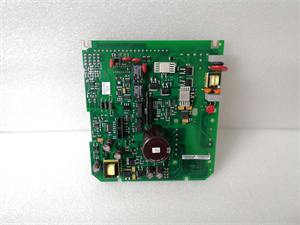

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO 14A – FR is a straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. The clearly marked terminals simplify the wiring process, reducing installation time. For maintenance, the module has built – in self – diagnostic functions that continuously monitor its operation. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the 14A – FR enables quick replacement, minimizing downtime. FOXBORO provides comprehensive technical support, including pre – installation guidance, on – site assistance if needed, and software updates (if applicable) to enhance performance and compatibility. Their team of experts is always available to address any questions or concerns, ensuring the 14A – FR operates optimally throughout its lifecycle.

Contact us now to get a customized solution that perfectly fits your industrial control needs.