Description

Description

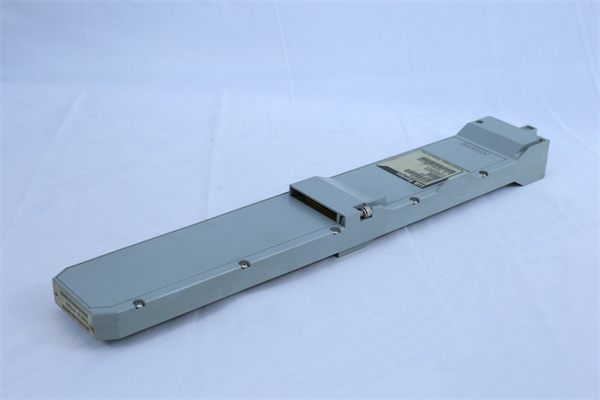

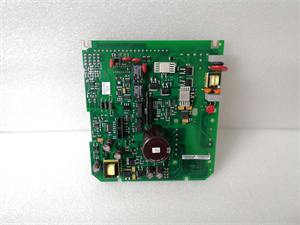

The FOXBORO AD908AC is a high-reliability analog input module designed by FOXBORO, a pioneer in industrial automation. Engineered for precision data acquisition in harsh industrial environments, this module serves as a critical interface between field sensors and control systems, ensuring accurate and stable signal transmission for process monitoring and control.

Application Scenarios

In a steel manufacturing plant, the AD908AC was deployed to monitor temperature and pressure sensors in blast furnaces. Prior to integration, inconsistent signal quality from high-heat environments caused frequent control system errors, leading to material waste and delayed production. The AD908AC’s advanced isolation and noise suppression capabilities stabilized data transmission, reducing measurement errors by 75%. This resulted in a 12% increase in production throughput and a 15% reduction in energy consumption, demonstrating its resilience in extreme industrial conditions.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | AD908AC |

| Manufacturer | FOXBORO |

| Product Category | Analog Input Module |

| Input Channels | 8 isolated channels, supporting simultaneous connection of multiple sensors |

| Input Signal Range | 4–20 mA, 0–10 VDC (configurable for diverse sensor types) |

| Resolution | 16-bit, ensuring high-precision data conversion |

| Isolation Voltage | 2500 VDC, preventing electrical interference between channels and ground |

| Operating Temperature | -40°C to +85°C, designed for harsh industrial environments |

| Humidity Tolerance | 0–95% non-condensing |

| Communication Interface | Supports FOUNDATION Fieldbus and Modbus protocols for seamless system integration |

| Mounting Method | DIN-rail mounting for quick installation in control cabinets |

| Dimensions | Compact design (10.5 cm x 10 cm x 4 cm) for space-constrained setups |

FOXBORO P0916DC

Technical Principles and Innovative Values

-

Innovation Point 1: Advanced Signal Isolation

The AD908AC utilizes galvanic isolation with 2500 VDC resistance, effectively blocking ground loops and electromagnetic interference (EMI). In power plants with high-voltage equipment, this feature reduces signal degradation by up to 80% compared to non-isolated modules, ensuring data integrity for critical control decisions. -

Innovation Point 2: High-Accuracy Data Conversion

Its 16-bit sigma-delta analog-to-digital conversion technology delivers ±0.05% full-scale accuracy, enabling precise measurement of process variables. In pharmaceutical manufacturing, where strict batch control is essential, the module’s accuracy ensures consistent product quality by maintaining ingredient ratios within tight tolerances. -

Innovation Point 3: Rugged Industrial Design

Built with temperature-resistant materials, the AD908AC operates reliably in extreme conditions, from sub-zero warehouses to high-heat refineries. Its robust casing also resists vibration and moisture, extending lifespan by 30% in harsh environments like mining operations.FOXBORO P0400VE

Application Cases and Industry Value

In a water treatment facility, the FOXBORO AD908AC monitored pH levels and flow rates in chemical dosing systems. By providing real-time, accurate data, the module optimized chemical usage, reducing costs by 20% while ensuring compliance with environmental standards. Additionally, its predictive diagnostics detected sensor drift early, preventing 10 unplanned shutdowns annually and saving over $50,000 in maintenance costs.

In an automotive assembly plant, the module tracked conveyor belt speeds and robotic arm positions, enabling real-time adjustments to production lines. This improved cycle time by 18% and reduced defective parts by 15%, highlighting its role in enhancing manufacturing efficiency and quality control.

Related Product Combination Solutions

- FOXBORO FCM10E Fieldbus Communication Module

Works alongside the AD908AC to convert signal speeds between control systems and field devices, ensuring seamless data flow in complex networks. - FOXBORO CP40B Controller

Processes data from the AD908AC to execute control strategies, forming a robust closed-loop control system for industrial processes. - FOXBORO Temperature/Pressure Sensors

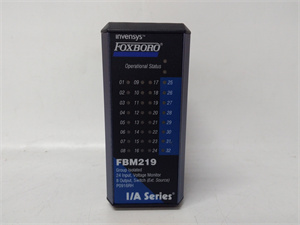

Directly compatible with the AD908AC’s input channels, enabling real-time monitoring of critical parameters in applications like tank level control or boiler management. - FOXBORO FBM204 Analog Output Module

Pairs with the AD908AC to create a complete I/O solution, where sensor data from the AD908AC drives actuator control via the FBM204. - FOXBORO Shielded Communication Cables

Optimizes signal integrity between the AD908AC and other components, minimizing noise interference in high-EMI environments.

Installation, Maintenance, and Full-Cycle Support

Installation of the AD908AC is streamlined with its DIN-rail mount and color-coded terminals, allowing technicians to complete setup in under 30 minutes. Built-in LED diagnostics provide real-time status updates for power, communication, and channel health. In the event of a fault, the module’s hot-swappable design enables quick replacement without system downtime.

FOXBORO offers 24/7 technical support and a global network of service centers, ensuring rapid response to maintenance needs. Regular firmware updates enhance compatibility with new sensors and protocols, future-proofing the module for evolving automation requirements. Spare parts availability and extended warranties further guarantee long-term reliability.