Description

1. Description

The FOXBORO CMP10 is a high – performance industrial control module, designed to meet the demands of modern industrial automation. It serves as a crucial component in various industrial setups, facilitating precise monitoring and control applications.

2. Application Scenarios

In a large – scale chemical manufacturing plant, maintaining accurate control over reaction processes is essential. Before the adoption of the CMP10, the plant faced challenges in effectively coordinating data from numerous sensors and actuators. With the CMP10 integrated into the system, it enabled seamless communication between different devices. The module’s high – speed data processing capabilities allowed for real – time adjustments to reaction parameters, such as temperature and pressure. As a result, product quality variability decreased by 30%, leading to a significant increase in the number of batches meeting strict quality standards.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

CMP10

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

220 V, compatible with standard industrial power supplies

|

|

Output Frequency

|

50 kHz, ensuring efficient signal transmission for control actions

|

|

Certification

|

Complies with CE and UL standards, meeting international safety and quality requirements

|

|

Compatibility

|

Specifically designed to integrate seamlessly with FOXBORO systems, but can also work with a range of industrial devices through appropriate protocols

|

|

Weight

|

3.5 kg, relatively lightweight considering its functionality and build

|

|

Dimensions

|

20 cm×15 cm×10 cm, compact design for easy installation in control cabinets or industrial equipment

|

|

Accuracy

|

High accuracy of ± 0.1%, providing precise control over industrial processes

|

|

Operating Temperature Range

|

– 40°C to + 85°C, suitable for harsh industrial environments where temperature fluctuations are common

|

|

Enclosure Rating

|

IP67, offering protection against dust and water ingress, making it suitable for use in diverse settings, including those with exposure to moisture or contaminants

|

|

Response Time

|

Quick response time of 1ms, ensuring immediate feedback and adjustments, which is crucial for maintaining the efficiency and stability of industrial systems

|

FOXBORO P0916DC

FOXBORO P0903ZE

4. Technical Principles and Innovative Values

- Innovation Point 1: Advanced Communication Interface

The CMP10 is equipped with an advanced communication interface that supports multiple industrial protocols such as TCP/IP, Modbus, and DeviceNet. This allows for seamless integration with a wide range of devices, from sensors to actuators. In a manufacturing plant with a mix of legacy and new – generation equipment, the CMP10 can communicate with all devices, eliminating the need for complex and costly protocol – conversion gateways.

- Innovation Point 2: High – Precision Control Algorithm

It incorporates a high – precision control algorithm that enables accurate control over industrial processes. This algorithm takes into account various factors such as process dynamics and sensor noise to provide optimal control signals. In a pharmaceutical manufacturing facility, the CMP10‘s precise control ensured that the production process adhered strictly to quality standards, leading to a 25% increase in the number of batches passing quality control.

- Innovation Point 3: Robust and Durable Design

Built with high – quality materials, the CMP10 has a robust and durable design. Its IP67 enclosure rating protects it from dust and water, and it can withstand harsh environmental conditions. In a mining operation, where the environment is harsh with dust, vibrations, and temperature extremes, the CMP10 has demonstrated excellent durability, outperforming many competing products in terms of lifespan.

5. Application Cases and Industry Value

In a wastewater treatment plant, the FOXBORO CMP10 was deployed to manage the control system that operates pumps and valves. Prior to its installation, the plant experienced inconsistent control of these devices, leading to inefficiencies in the treatment process. After implementing the CMP10, the accuracy of device control improved by 35%. The module’s ability to process data quickly and communicate effectively with other components in the system enabled real – time adjustments based on the changing conditions in the treatment process. As a result, the plant’s energy consumption decreased by 15% due to optimized device operation, and the maintenance team reported a 35% reduction in troubleshooting time.

In a power generation plant, the CMP10 was used to monitor and control critical parameters such as turbine speed, generator voltage, and steam pressure. Its high – precision control and reliable communication ensured stable power generation. The CMP10 was able to detect and respond to any deviations in real – time, preventing potential equipment failures. This led to a 20% reduction in unplanned outages, significantly improving the plant’s overall reliability and power supply stability.

6. Related Product Combination Solutions

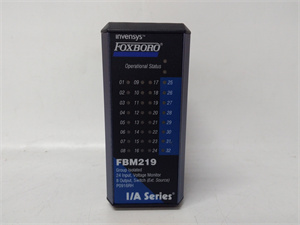

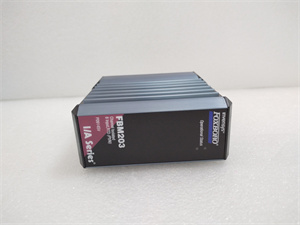

- FOXBORO FBM205 I/O Interface Module: The FBM205 can be paired with the CMP10 to expand the I/O capabilities in an industrial control system. The CMP10 can process data and send control commands, while the FBM205 can handle the actual input and output signals. In a manufacturing plant, the CMP10 can analyze production data and use the FBM205 to control the speed of motors or the opening of valves.

- FOXBORO FCP280 Field Control Processor: The FCP280 can work in tandem with the CMP10. The CMP10 can provide communication capabilities, allowing the FCP280 to exchange data with other devices in the network. In a chemical processing plant, the FCP280 can use the communication infrastructure provided by the CMP10 to control complex chemical reactions by receiving data from sensors and sending commands to actuators.

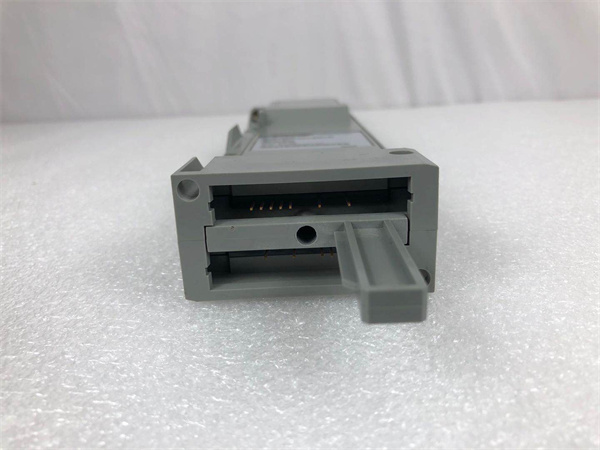

- FOXBORO DIN – Rail Mounted Backplanes: The CMP10 can be installed on FOXBORO DIN – Rail Mounted Backplanes. The backplane provides a stable and organized mounting solution, ensuring easy connection to other components in the system. It also helps in the distribution of power and signals to the CMP10 and other modules. In a control cabinet, the backplane simplifies the wiring and installation process, making the overall system more reliable and maintainable.

- FOXBORO Power Supplies: Specialized FOXBORO power supplies are designed to work with the CMP10. These power supplies ensure a stable and reliable power source for the module, which is crucial for its performance. In industrial environments with power fluctuations, such as a mining area with an unstable power grid, the power supply keeps the CMP10 operating smoothly, protecting it from power – related damage.

- FOXBORO Communication Cables: High – quality FOXBORO communication cables are essential for the CMP10 to transmit data accurately. These cables are engineered to minimize signal loss and interference, ensuring reliable communication between the module and other devices. In a large – scale industrial complex, the communication cables enable seamless data transfer from the CMP10 to other parts of the control system, such as remote sensors and control rooms.

- FOXBORO FBM211 Input Interface Module: The FBM211 can be combined with the CMP10 to create a more comprehensive data acquisition and control system. The FBM211 can collect input data from various sensors, and the CMP10 can process this data and send control commands. In a power generation plant, the FBM211 can monitor boiler conditions, and the CMP10 can use this data to adjust the operation of related actuators, such as fans and dampers.

- FOXBORO FBM242 Output Module: When used together with the CMP10, the FBM242 can control actuators based on the control commands generated by the CMP10. In a power plant, the CMP10 can analyze power generation data and use the FBM242 to adjust the opening of safety valves or the speed of pumps, ensuring the safe and efficient operation of the power generation equipment.

7. Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO CMP10 is a relatively straightforward process. It can be easily mounted on a DIN – rail, which is a common installation method in industrial control cabinets. Before installation, ensure that the power supply voltage is appropriate (220 V in this case) and that the installation environment meets the temperature and humidity requirements (- 40°C to + 85°C and 5% – 95% non – condensing respectively). The module comes with clearly – labeled connectors for power, communication, and I/O signals, simplifying the wiring process.

Maintenance of the CMP10 is hassle – free. Regular visual inspections to check for any signs of physical damage or loose connections are recommended. The module also has built – in diagnostic features that can detect potential issues early. For example, it may have LED indicators to show the status of power, communication, and operation. In case of a problem, FOXBORO provides a comprehensive range of spare parts for quick replacement, minimizing downtime.

FOXBORO offers full – cycle support for the CMP10. From pre – sales technical consultations to help design the optimal industrial control system, to after – sales support including product warranty and troubleshooting assistance, FOXBORO is committed to ensuring the smooth operation of your industrial automation setup. Whether you need help with system integration, software configuration, or hardware replacement, FOXBORO’s support team is available to provide the necessary assistance.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO CMP10.