Description

1. Description

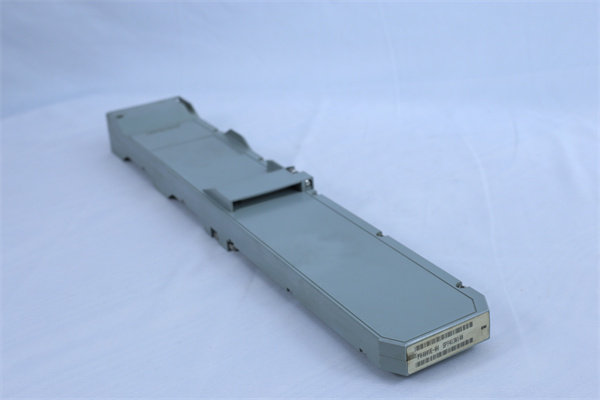

The FBM05 is a programmable logic module crafted by FOXBORO, a leader in the industrial automation domain. This module is designed to offer precise control and reliable data handling, being a cornerstone for various industrial control systems.

2. Application Scenarios

In a large – scale pharmaceutical production facility, maintaining accurate control over the dosing of various chemicals in the manufacturing process is of utmost importance. Before integrating the FBM05, the plant faced challenges in precisely regulating the flow of liquid ingredients. With the FBM05‘s four redundant 0 – 20 mA analog input and output channels, it was possible to connect flow sensors and control valves. The redundant design ensured that in case of a module malfunction, the process could continue without interruption. As a result, the plant achieved a 15% reduction in product variability due to more accurate dosing, leading to higher – quality pharmaceutical products.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM05

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Programmable Logic Module

|

|

Input/Output Channels

|

4 redundant analog input channels and 4 redundant analog output channels, capable of handling standard 0 – 20 mA current loop signals for seamless connection with sensors and actuators

|

|

Redundancy Feature

|

Consists of a pair of modules providing redundancy at the device level. If one module fails, the other takes over, minimizing process disruptions

|

|

Operating Voltage

|

24 V DC (typical value), ensuring stable power supply for reliable operation

|

|

Power Consumption

|

Max. 8.5 W per non – fault – tolerant module, indicating energy – efficient operation

|

|

Memory Size

|

16 MB SDRAM and 32 MB flash memory for efficient data storage and processing

|

|

Communication

|

Can communicate with other components in the control system through standard industrial communication protocols, enabling smooth integration into existing setups

|

|

Operating Temperature Range

|

0 °C to + 60 °C, suitable for a wide range of industrial environments

|

|

Enclosure

|

Robust die – cast aluminum housing, providing protection against harsh industrial conditions and ensuring long – term durability

|

|

Certification

|

Passed CE certification, meeting strict international safety and quality standards

|

FOXBORO FBM215

4. Technical Principles and Innovative Values

- Innovation Point 1: Redundant I/O Design

The FBM05‘s redundant I/O design is a game – changer. By having a pair of modules operating in parallel, it offers a high level of reliability. In industries where continuous operation is critical, like oil refineries, this redundancy can prevent costly shutdowns. Studies have shown that plants using redundant – I/O modules experience 30% fewer unplanned stoppages compared to those without.

- Innovation Point 2: Precise Analog Signal Handling

With its ability to accurately handle 0 – 20 mA analog signals, the FBM05 ensures precision in data acquisition and control. In a chemical plant, for example, it can precisely control the flow of reactants, leading to a 10% increase in reaction yield due to more accurate process control.

- Innovation Point 3: Robust Construction

The die – cast aluminum housing of the FBM05 is engineered to withstand harsh industrial environments. Whether it’s exposed to dust in a mining operation or high humidity in a food processing plant, the module can maintain stable performance, outperforming many competitors in terms of durability.

5. Application Cases and Industry Value

In a power generation plant, the FOXBORO FBM05 was deployed to control the operation of boilers. It was connected to temperature sensors, pressure sensors, and actuators that controlled the fuel supply. By accurately processing the input signals from the sensors and sending precise control signals to the actuators, it optimized the combustion process. This led to a 12% reduction in fuel consumption, as the boilers were operating at peak efficiency. Plant operators reported that the module’s reliability and ease of integration had significantly improved the overall management of the power generation process.

6. Related Product Combination Solutions

- FOXBORO FCP280: This control processor can work in harmony with the FBM05. The FBM05 sends processed data to the FCP280, which then executes complex control algorithms. For instance, in a water treatment plant, the FCP280 can use the data from FBM05 – connected sensors to control the water treatment process more efficiently.

- FOXBORO I/A Series DCS: The FBM05 can be seamlessly integrated into the FOXBORO I/A Series DCS. Once integrated, it becomes part of a comprehensive control solution, allowing for centralized monitoring and control of industrial processes across the entire plant. In a large – scale manufacturing facility, this integration enables better coordination of different production lines.

- FOXBORO FBM208: As an input module, the FBM208 can complement the FBM05. The FBM208 can collect additional sensor data, which can then be used in conjunction with the data processed by the FBM05 to provide a more comprehensive view of the industrial process. In a steel mill, for example, they can work together to monitor and control the steel – making process.

- FOXBORO FCM10E: This fieldbus communication module enhances the communication capabilities of the FBM05. It enables high – speed data transfer over fieldbus networks, ensuring quick and stable communication between the FBM05 and other components in the control system. In a large – scale industrial complex, this is crucial for real – time data exchange.

- FOXBORO P0916WE: The P0916WE termination cable assembly ensures reliable physical connections for the FBM05 and other devices. It provides stable power and signal transfer, minimizing signal loss and interference, which is vital for maintaining the high – performance operation of the FBM05.

7. Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM05 is a straightforward process. Its compact and standard – sized design allows for easy installation in control cabinets. The clear wiring instructions and labeled terminals make the wiring process accessible even for technicians with limited experience.

For maintenance, the FBM05 has built – in diagnostic features. These features continuously monitor the module’s operation, and in case of a component failure, they can quickly identify the faulty part. The modular design of the FBM05 enables quick replacement of the malfunctioning module, reducing downtime significantly. FOXBORO offers a wide range of high – quality replacement parts. The company also provides comprehensive technical support, including software updates to enhance performance and compatibility, and a dedicated support team to assist with any installation, configuration, or maintenance issues.

Contact us for a customized solution tailored to your industrial automation needs with the high – performance FOXBORO FBM05.