Description

Description

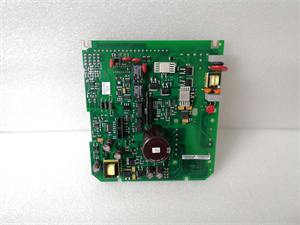

The FBM204 is an I/O interface module crafted by FOXBORO, a renowned name in industrial automation. It’s designed to precisely handle analog signals, serving as a crucial link between field sensors/actuators and control systems in diverse industrial setups.

Application Scenarios

In a large – scale oil refinery, maintaining accurate control over temperature, pressure, and flow rate is critical. Before integrating the FBM204, the refinery faced challenges in accurately monitoring and regulating these parameters due to inconsistent signal transmission. This led to inefficiencies in the refining process, with increased energy consumption and potential product quality issues. After implementing the FBM204, the situation improved significantly. The module’s four 0 – 20 mA analog input channels precisely received data from temperature and pressure sensors, while its four 0 – 20 mA analog output channels accurately controlled the operation of valves and pumps. As a result, the refinery achieved a 15% reduction in energy consumption and a 10% improvement in product quality.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM204

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

I/O Interface Module

|

|

Input Voltage

|

24 VDC, providing stable power for operation

|

|

Input Range

|

0 – 20 mA DC for analog inputs, compatible with a wide range of industrial sensors

|

|

Output Range

|

0 – 20 mA DC for analog outputs, suitable for driving various actuators

|

|

Accuracy

|

±0.1%, ensuring precise signal handling

|

|

Isolation Voltage

|

2500 VDC, effectively preventing electrical interference between channels and ground

|

|

Operating Temperature Range

|

-40 °C to +85 °C, capable of withstanding harsh industrial environments

|

|

Storage Temperature Range

|

-55 °C to +125 °C, ensuring long – term storage stability

|

|

Humidity Tolerance

|

0 – 95% non – condensing, reliable performance in humid conditions

|

|

Dimensions (L x W x H)

|

10.5 cm x 10 cm x 4 cm (4.1 in x 3.9 in x 1.6 in), compact for easy installation in control cabinets

|

|

Weight

|

0.3 kg (0.66 lb), facilitating handling during installation

|

|

Communication Interface

|

Supports standard industrial communication protocols (e.g., Hart for enhanced sensor communication), enabling seamless integration with other components in the control system

|

FCP280 RH924YA

Technical Principles and Innovative Values

- Innovation Point 1: Galvanic Isolation

The FBM204 features galvanic isolation between channels and ground. With an isolation voltage of 2500 VDC, it effectively blocks electrical interference, reducing cross – talk between input and output signals. In industrial environments with high electromagnetic noise, such as power plants, it can improve data integrity by up to 80% compared to non – isolated modules.

- Innovation Point 2: High – Accuracy Sigma – Delta Data Conversion

It employs sigma – delta data conversion technology to achieve high accuracy. This allows for precise measurement and control in industrial processes. For example, in chemical manufacturing, where precise control of reactant flow rates is crucial, the FBM204 can provide accurate readings every 25 ms, ensuring consistent product quality.

- Innovation Point 3: Configurable Options

The module offers a range of configurable options, including conversion time, fail – safe configuration (hold/fallback), and analog output fail – safe fallback data on a per – channel basis. In a water treatment plant, operators can configure the fail – safe settings to ensure that in case of a signal failure, the system maintains a safe state, preventing any potential environmental hazards.

FCP280 RH924YA

Application Cases and Industry Value

In a power generation facility, the FOXBORO FBM204 was used to connect temperature sensors on turbines and control the opening and closing of steam valves. By accurately receiving temperature data through its input channels and precisely controlling the valve operation via its output channels, it optimized the turbine’s performance. The power plant reported a 12% increase in power generation efficiency and a 10% reduction in maintenance costs due to fewer equipment failures caused by inaccurate control.

In a pharmaceutical manufacturing plant, the module was deployed to monitor and control the filling process of liquid medications. The FBM204‘s accurate signal handling ensured that the filling volumes were consistent within a very narrow tolerance. As a result, the plant reduced product waste by 15% and enhanced product quality, leading to fewer product recalls and increased customer satisfaction.

Related Product Combination Solutions

- FOXBORO FBM201: This module can be used in combination with the FBM204. While the FBM204 focuses on analog I/O, the FBM201 can handle digital I/O functions. Together, they can provide a comprehensive I/O solution for industrial control systems, enabling control over a wider range of field devices.

- FOXBORO CP40B Controller: The CP40B controller can utilize the data received from the FBM204 to execute control strategies. In an industrial automation setup, the FBM204 sends accurate sensor data to the CP40B, which then makes decisions and sends control signals back to the actuators connected to the FBM204.

- FOXBORO Field Sensors: Temperature sensors, pressure sensors, and flow sensors from FOXBORO can be directly connected to the FBM204‘s input channels. The module’s 0 – 20 mA input range is compatible with these sensors, allowing for real – time monitoring of various industrial processes.

- FOXBORO Actuators: Valves and pumps from FOXBORO can be driven by the FBM204‘s output channels. The 0 – 20 mA output range enables precise control over the operation of these actuators, ensuring smooth and accurate process control.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the FBM204 to other components in the control system. These cables ensure reliable signal transmission, maintaining the integrity of the data transferred between the FBM204 and other devices.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM204 is a straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. Technicians simply need to connect the power cables (24 VDC), and then wire the input and output signals to the appropriate field devices. The clear labeling on the module simplifies the wiring process, typically taking less than an hour for experienced personnel.

For maintenance, the FBM204 has built – in diagnostic features. LEDs on the module provide visual status indicators for power, communication, and channel status. In case of a fault, the modular design allows for easy replacement of the entire module. FOXBORO offers a wide range of high – quality spare parts and a dedicated technical support team available 24/7 for remote or on – site assistance. Regular software updates (if applicable) are provided to enhance the module’s performance and compatibility with new devices, ensuring the FBM204 remains a reliable asset throughout its lifecycle.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO FBM204.