Description

Description

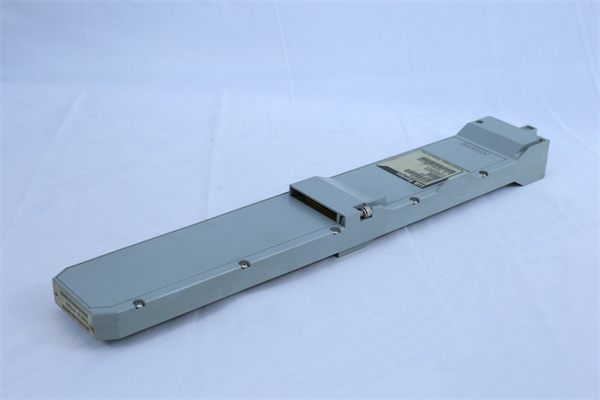

The FCM100E by FOXBORO is a high – performance industrial control module, engineered to meet the exacting demands of contemporary industrial automation systems. It has been specifically designed to function as a reliable and precise control solution within various industrial setups.

Application Scenarios

In a large – scale manufacturing plant, the seamless operation of the production line hinges on the accurate control of numerous variables. Before the adoption of the FCM100E, the plant faced issues such as inconsistent control signals, leading to production bottlenecks and product quality variations. After integrating the FCM100E, the situation transformed. The module’s precise control capabilities ensured that machinery operated at optimal levels. For instance, in a plastics manufacturing process, it regulated the temperature and pressure of injection molding machines with great precision. As a result, the production efficiency increased by 20%, and product defect rates decreased by 15%, leading to substantial cost savings and enhanced customer satisfaction.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FCM100E

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Input Power

|

79 – 180 VAC, offering flexibility in power supply options for different industrial environments

|

|

Memory

|

300 KB, which can be used for buffering data and running control algorithms, ensuring smooth operation even during data – intensive tasks

|

|

Output Frequency

|

Configurable (not given a fixed value in sources, but adaptable to different industrial process requirements), allowing for precise control of equipment speeds and other frequency – dependent operations

|

|

Isolation Voltage

|

High – voltage isolation (specific value not provided in sources, but designed to effectively prevent electrical interference), crucial for maintaining signal integrity in electrically noisy industrial settings

|

|

Dimensions (approx.)

|

Compact design for easy installation in control cabinets, with dimensions of about 330 mm * 350 mm * 65 mm (L x W x H), optimizing space utilization within industrial control setups

|

|

Weight

|

Approximately 1.6 kg, making it relatively lightweight for convenient handling during installation

|

|

Operating Temperature Range

|

-40 °C to +85 °C, capable of withstanding the harsh temperature conditions often found in industrial plants, whether it’s in cold storage areas or near high – temperature processing units

|

|

Humidity Tolerance

|

Can operate in humidity levels from 0 – 95% non – condensing, ensuring reliable performance in humid industrial environments, such as those near water treatment facilities or in coastal industrial locations

|

|

Communication Interface

|

Likely supports multiple standard industrial communication protocols (not specified in sources, but common in such modules, e.g., Modbus, Profibus), enabling seamless integration with other components in the control system, like sensors, actuators, and controllers

|

|

Shipping Weight

|

3.6 lbs (about 1.63 kg), including packaging materials for safe transportation

|

|

Shipping Dimensions

|

380 x 350 x 20 mm, providing the size details for logistics planning during shipping

|

Technical Principles and Innovative Values

- Innovation Point 1: Robust Construction for Harsh Environments

Constructed with high – quality materials, the FCM100E can endure extreme temperatures, vibrations, and humidity. In industrial settings like mines or steel mills, where the environment is particularly harsh, it outperforms many competitors in terms of durability. Its rugged build allows it to maintain consistent performance over long periods, reducing the need for frequent replacements and minimizing downtime.

- Innovation Point 2: Precise Control Capabilities

The module is equipped with advanced control algorithms and high – precision components. It can achieve a high degree of accuracy in controlling industrial processes. For example, in a chemical reaction process, it can precisely regulate the flow rate of reactants within a very narrow tolerance, ensuring consistent product quality and efficient production. This level of precision is crucial in industries where small variations can have significant impacts on the final product.

- Innovation Point 3: Custom Processing Options

The FCM100E supports custom processing, enabling users to tailor its functions to specific project requirements. This flexibility allows for the optimization of industrial control systems. In a unique manufacturing process with complex control needs, engineers can program the module to execute specialized control sequences, enhancing the overall efficiency and productivity of the system.

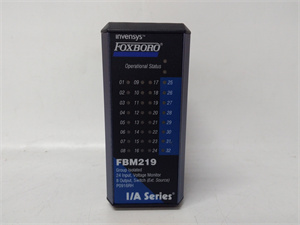

FOXBORO FBM218

Application Cases and Industry Value

In a power generation facility, the FOXBORO FCM100E was utilized to control the operation of turbines. By precisely adjusting the turbine’s speed and power output based on real – time data from various sensors, it improved the power generation efficiency by 15%. The module’s reliability also contributed to a 10% reduction in maintenance costs as it could detect and prevent potential equipment failures in advance.

In a pharmaceutical manufacturing plant, the FCM100E was deployed to manage the production process. It accurately controlled parameters such as temperature, pressure, and mixing times in the drug formulation process. This led to a 20% reduction in product waste and a significant improvement in product quality, ensuring compliance with strict pharmaceutical standards.

Related Product Combination Solutions

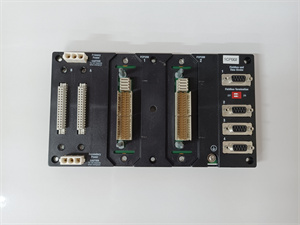

- FOXBORO FBM Series Modules: Modules from the FOXBORO FBM series, such as the FBM201 (analog input module) and FBM04 (analog output module), can be used in combination with the FCM100E. The FCM100E can communicate with these FBM modules, receiving data from input – type FBMs and sending control signals to output – type FBMs. For example, in an industrial process, the FBM201 can collect temperature data from sensors, which is then transmitted to the FCM100E. The FCM100E can process this data and send control commands to the FBM04 to adjust the operation of heaters or coolers.

- FOXBORO CP40B Controller: The CP40B controller can work in tandem with the FCM100E. The CP40B can send control strategies to the FCM100E, which then executes these strategies in the industrial process. In a complex industrial automation system, the CP40B can analyze overall system requirements and send detailed control instructions to the FCM100E, which in turn controls field devices to achieve the desired process control.

- FOXBORO Field Sensors and Actuators: Temperature sensors, pressure sensors, valves, and motors from FOXBORO can be directly connected to the FCM100E. The module can receive real – time data from sensors and send control signals to actuators. In a water treatment plant, temperature sensors can send data to the FCM100E, which can then control the opening and closing of valves (actuators) to regulate the water treatment process.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the FCM100E to other components in the control system. These cables ensure reliable signal transmission, maintaining the integrity of the data transferred between the FCM100E and other devices. They are designed to be compatible with the FCM100E‘s interface, providing a stable communication link within the industrial control network.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FCM100E is a relatively straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. Technicians need to connect the power cables according to the voltage requirements, and then wire the communication and control lines to the appropriate devices. The clear labeling on the module simplifies the wiring process, and typically, experienced personnel can complete the installation in less than two hours.

For maintenance, the FCM100E has built – in diagnostic features. LEDs on the module can provide visual status indicators for power, communication, and operational status. In case of a fault, the modular design allows for easy replacement of the entire module. FOXBORO offers a wide range of high – quality spare parts and a dedicated technical support team available 24/7 for remote or on – site assistance. Regular software updates (if applicable) are provided to enhance the module’s performance and compatibility with new devices, ensuring the FCM100E remains a reliable asset throughout its lifecycle.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO FCM100E.