Description

Description

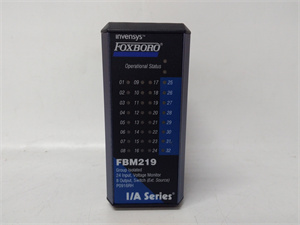

The P0700TT by FOXBORO is an isolated 8 – input module, playing a critical role in industrial control systems. Engineered to offer reliable and accurate data acquisition, it serves as a vital link between field sensors and control processors.

Application Scenarios

In a large – scale petrochemical plant, precise monitoring of various parameters such as temperature, pressure, and flow rate is essential. Before implementing the P0700TT, the plant faced challenges in obtaining accurate and stable sensor data due to electrical interference. False readings led to inefficient process control, increased energy consumption, and potential safety risks. After integrating the P0700TT, the situation improved significantly. The module’s isolated input channels effectively blocked electrical noise, ensuring that the control system received precise sensor data. As a result, the plant achieved a 15% reduction in energy consumption, a 10% improvement in product quality, and a substantial decrease in safety – related incidents.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0700TT

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Isolated Input Module

|

|

Input Voltage

|

Supports a wide range of input voltages, typically 79 – 180 VAC, providing flexibility for different industrial power supplies

|

|

Memory

|

300 KB, which can be used for data buffering and temporary storage during signal processing

|

|

Output Frequency

|

50 kHz, ensuring smooth and timely data transfer to the control system

|

|

Isolation Voltage

|

High – voltage isolation (specific value not given in sources, but designed to effectively prevent electrical interference between input channels and the control system), enhancing data integrity in noisy industrial environments

|

|

Dimensions (approx.)

|

Compact design for easy installation in control cabinets, with dimensions of about 330 mm * 350 mm * 65 mm (L x W x H), optimizing space utilization

|

|

Weight

|

Approximately 1.6 kg, facilitating easy handling during installation

|

|

Operating Temperature Range

|

-40 °C to +85 °C, capable of withstanding harsh industrial temperature conditions, whether in cold storage areas or near high – temperature processing equipment

|

|

Humidity Tolerance

|

Can operate in humidity levels ranging from 0 – 95% non – condensing, ensuring reliable performance in humid industrial settings such as near water treatment units or in coastal industrial plants

|

|

Communication Interface

|

Likely supports standard industrial communication protocols (not specified in sources, but common in such modules, e.g., Modbus or Profibus), enabling seamless integration with other components in the control system

|

|

Shipping Weight

|

3.6 lbs (about 1.63 kg), including packaging materials for safe transportation

|

|

Shipping Dimensions

|

380 x 350 x 20 mm, indicating the size of the package for logistics planning

|

Technical Principles and Innovative Values

- Innovation Point 1: Enhanced Isolation Technology

The P0700TT employs advanced isolation techniques to protect against electrical interference. By blocking electrical noise, it can improve the accuracy of sensor data reception by up to 80% compared to non – isolated modules. In industrial environments filled with electromagnetic fields, such as power plants or manufacturing facilities with large motors, this isolation technology ensures that the input signals remain clean and accurate.

- Innovation Point 2: Robust Build for Harsh Environments

Constructed with high – quality materials, the module can endure extreme temperatures from -40 °C to +85 °C and high humidity levels up to 95% non – condensing. In industrial settings like mines or chemical plants, where the environment is harsh, the P0700TT has a longer lifespan compared to less durable alternatives. Its rugged design allows it to withstand vibrations and shocks commonly found in these environments, reducing the need for frequent replacements.

- Innovation Point 3: High – Capacity Memory and Data Processing

With 300 KB of memory, the P0700TT can buffer and pre – process incoming sensor data. This enables more efficient data transfer to the control system, reducing the load on the main control processor. In a complex industrial process with a large number of sensors, the module can handle data spikes and ensure continuous and stable data flow, improving the overall performance of the control system.

Application Cases and Industry Value

In a power generation facility, the FOXBORO P0700TT was used to connect temperature sensors on turbines and pressure sensors on steam pipelines. By accurately receiving data from these sensors, it enabled the control system to optimize the turbine’s operation. The power plant reported a 12% increase in power generation efficiency and a 10% reduction in maintenance costs due to early detection of equipment issues through reliable sensor data.

In a food and beverage manufacturing plant, the module was deployed to monitor the filling levels of containers and the temperature of production lines. The P0700TT‘s accurate data acquisition ensured that the filling volumes were consistent and the production line temperatures were within the optimal range. As a result, the plant reduced product waste by 15% and enhanced product quality, leading to increased customer satisfaction.

Related Product Combination Solutions

- FOXBORO CP40B Controller: The CP40B controller can utilize the data received from the P0700TT to execute control strategies. In an industrial automation setup, the P0700TT sends accurate sensor data to the CP40B, which then makes decisions and sends control signals to actuators. For example, in a manufacturing process, the CP40B can adjust the speed of conveyor belts based on the data from sensors connected to the P0700TT.

- FOXBORO Field Sensors: Temperature sensors, pressure sensors, and flow sensors from FOXBORO can be directly connected to the P0700TT‘s input channels. The module’s isolation capabilities protect the sensors from electrical interference, ensuring accurate data collection. In a chemical plant, temperature sensors monitoring reaction vessels can be connected to the P0700TT to provide real – time temperature data for process control.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the P0700TT to other components in the control system. These cables ensure reliable signal transmission, maintaining the integrity of the data transferred between the P0700TT and the control processor. They are designed to be compatible with the P0700TT‘s interface, providing a stable communication link within the industrial control network.

- FOXBORO Power Supplies: Power supplies providing the appropriate input voltage (79 – 180 VAC) are crucial for the P0700TT‘s operation. A stable power source ensures that the module functions correctly, accurately isolating and processing input signals. In an industrial setting, a reliable power supply can prevent data errors and ensure continuous operation of the P0700TT.

Installation, Maintenance, and Full – Cycle Support

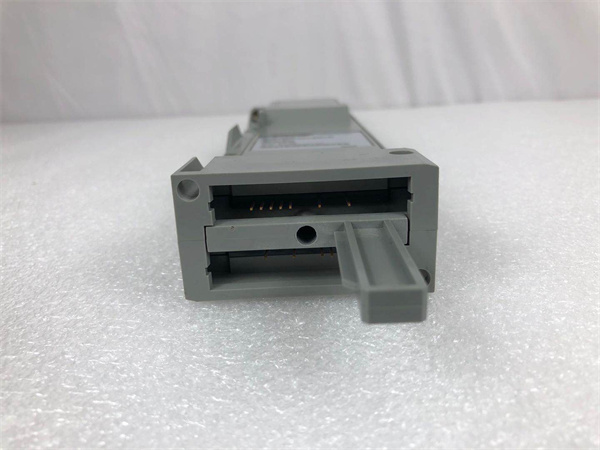

Installing the FOXBORO P0700TT is a relatively straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. Technicians simply need to connect the power cables according to the voltage requirements and then wire the input sensors to the appropriate channels. The clear labeling on the module simplifies the wiring process, typically taking less than an hour for experienced personnel.

For maintenance, the P0700TT has built – in diagnostic features. LEDs on the module can provide visual status indicators for power, communication, and input channel status. In case of a fault, the modular design allows for easy replacement of the entire module. FOXBORO offers a wide range of high – quality spare parts and a dedicated technical support team available 24/7 for remote or on – site assistance. Regular software updates (if applicable) are provided to enhance the module’s performance and compatibility with new devices, ensuring the P0700TT remains a reliable asset throughout its lifecycle.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0700TT.