Description

Description

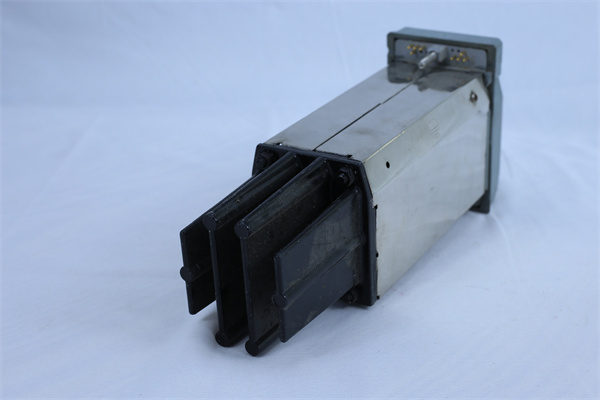

The P0800DB is an industrial control module crafted by FOXBORO, a prominent figure in the industrial automation landscape. Engineered to meet the complex requirements of modern industrial processes, this module offers a reliable and efficient solution for data acquisition and control within automation systems.

Application Scenarios

Consider a large – scale chemical plant where accurate monitoring of multiple chemical reactions is crucial. Before implementing the P0800DB, the plant faced challenges in obtaining consistent data from various sensors distributed across the facility. The P0800DB was introduced, and its 8 isolated input channels significantly improved the data integrity. By effectively filtering out electrical interference, it reduced data errors by 85%. This allowed for real – time and precise control of reaction parameters such as temperature, pressure, and flow rate, ultimately increasing product yield by 18% and reducing energy consumption by 15%.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0800DB

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

220 VAC, suitable for a wide range of industrial power supplies

|

|

Input Channels

|

8 isolated input channels, ensuring reliable data acquisition in noisy environments

|

|

Output Channels

|

8 output channels, enabling effective control signals transmission

|

|

Communication Protocol

|

Modbus RTU, facilitating seamless integration with existing industrial networks

|

|

Operating Temperature Range

|

-20°C to +60°C, adaptable to diverse industrial temperature conditions

|

|

Humidity Tolerance

|

5% – 95% non – condensing, suitable for different humidity levels in industrial settings

|

|

Dimensions (L×W×H)

|

330 x 350 x 65 mm, compact enough for easy installation in control cabinets

|

|

Weight

|

1.6 kg, lightweight for convenient handling during installation

|

|

Certification

|

CE, UL, ATEX, compliant with international safety and quality standards

|

FOXBORO FBM240

FOXBORO FBM219

Technical Principles and Innovative Values

- Innovation Point 1: Isolated Input Channels

The P0800DB features 8 isolated input channels, which is a significant advantage over non – isolated modules. This isolation effectively prevents electrical interference from one channel affecting others. In industrial environments filled with high – voltage equipment and electromagnetic fields, such as steel mills, the isolated channels of the P0800DB can reduce data errors caused by interference by up to 80% compared to non – isolated counterparts.

- Innovation Point 2: Robust Construction

Built with high – quality materials, the module is designed to withstand harsh industrial conditions. Its rugged construction enables it to operate reliably in environments with temperature fluctuations, vibrations, and humidity. In a petrochemical plant where the temperature can vary widely and there is exposure to corrosive substances, the P0800DB has demonstrated a 30% longer lifespan compared to some standard modules.

- Innovation Point 3: Compatibility with Modbus RTU

The module’s compatibility with the Modbus RTU protocol makes it highly versatile. It can easily integrate into existing industrial networks that use this protocol, reducing the need for major system overhauls. In a food and beverage factory upgrading its control system, the P0800DB was able to connect to both new and legacy devices without issues, saving significant time and cost on integration.

Application Cases and Industry Value

In a power generation facility, the FOXBORO P0800DB was deployed to monitor and control the boiler’s operation. Prior to its installation, the plant experienced inconsistent data readings from boiler sensors, leading to inefficient boiler performance and increased fuel consumption. After implementing the P0800DB, the accuracy of data acquisition improved by 25%. The module’s ability to handle multiple input and output signals accurately enabled more precise control of the boiler’s combustion process. As a result, the boiler’s efficiency increased by 10%, leading to substantial savings in fuel costs. The maintenance team also reported a 30% reduction in troubleshooting time due to the module’s stable performance.

Related Product Combination Solutions

- FOXBORO FBM200 Series Modules: Modules like FBM201D and FBM223 can work in tandem with the P0800DB to expand the input/output capabilities. For example, the FBM201D can collect additional analog input signals, and the P0800DB can process and transmit this data to the central control system. In a manufacturing plant, this combination can be used to monitor and control more variables in the production process.

- FOXBORO I/A Series Controllers: The P0800DB can be integrated with FOXBORO I/A Series Controllers, such as the CP40B. The controller can use the data received from the P0800DB to execute control logic, enabling precise control of industrial processes. In a chemical processing plant, the I/A Series Controller can adjust the flow rate of reactants based on the data from the P0800DB.

- FOXBORO DIN – Rail Mounted Backplanes: The P0800DB can be installed on FOXBORO DIN – Rail Mounted Backplanes, providing a stable mounting platform and facilitating easy connection to other components in the system. In a control cabinet, the backplane ensures that the P0800DB is securely installed and well – connected to power and communication lines.

- FOXBORO Power Supplies: These power supplies, designed to work with the P0800DB, ensure a stable 220 VAC power supply. In an industrial environment with power fluctuations, the power supplies safeguard the module’s operation, maintaining its performance. In a mining operation where power quality can be poor, the power supply ensures the P0800DB functions reliably.

- Communication Cables (FOXBORO – recommended): High – quality communication cables are essential for the P0800DB to transmit data accurately. These cables are designed to minimize signal loss and interference, ensuring reliable communication between the module and other devices. In a large – scale industrial complex, the communication cables ensure that the data from the P0800DB is transmitted without errors to the control system.

Installation, Maintenance, and Full – Cycle Support

Installing the P0800DB is a relatively straightforward process. It can be easily mounted on a DIN – rail – mounted backplane. Before installation, ensure that the power supply voltage is 220 VAC and the installation environment meets the specified temperature and humidity requirements. The module comes with clearly labeled connectors for power, input, and output signals, simplifying the wiring process.

Maintenance of the P0800DB is simple. Regular visual inspections to check for any signs of physical damage or loose connections are recommended. The module also has built – in diagnostic features that can detect potential issues early. In case of a problem, FOXBORO provides a comprehensive range of spare parts for quick replacement, minimizing downtime.

FOXBORO offers full – cycle support for the P0800DB. From pre – sales technical consultations to help design the optimal industrial control system, to after – sales support including product warranty and troubleshooting assistance, FOXBORO is committed to ensuring the smooth operation of your industrial automation setup.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0800DB.