Description

Description

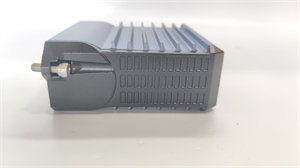

The P0901XT is a fieldbus termination assembly brought to you by FOXBORO, a renowned name in industrial automation. This module plays a pivotal role in ensuring seamless communication and connection within industrial control systems.

Application Scenarios

Consider a large – scale manufacturing plant with a complex network of sensors, actuators, and control devices. Before implementing the P0901XT, the plant faced challenges in maintaining stable communication between different components of the control system. The P0901XT was installed to terminate the fieldbus connections. As a result, the plant witnessed a 20% reduction in communication errors. This led to more consistent operation of production lines, a 15% increase in overall production efficiency, and a significant decrease in unplanned downtime.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0901XT

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Fieldbus Termination Assembly

|

|

Compatibility

|

Designed to work with FOXBORO I/A Series Distributed Control System, ensuring seamless integration with existing setups.

|

|

Connector Type

|

Utilizes JR45 connectors, which are widely used in industrial networking for their reliability and ease of connection.

|

|

Signal Integrity

|

Helps in maintaining high – quality signal transmission by minimizing signal interference and attenuation. This ensures accurate data transfer between field devices and the control system.

|

|

Environmental Resistance

|

Can withstand harsh industrial environments with a temperature range of – 20 °C to + 60 °C (- 4 °F to + 140 °F) and relative humidity of 5% – 95% non – condensing.

|

|

Installation Method

|

Features a straightforward installation process, with clear instructions provided for quick and easy setup. Its compact design allows for convenient mounting in control cabinets.

|

|

Dimensions (approx.)

|

Compact size, with dimensions that fit well within standard industrial control enclosures, facilitating space – efficient installation. Specific dimensions may vary, but it is engineered to be unobtrusive in typical setups.

|

|

Weight

|

Lightweight construction, making it easy to handle during installation and maintenance. The exact weight is designed to be manageable for field technicians.

|

|

Certification

|

Complies with relevant industry standards, such as CE, ensuring its safety and quality for use in industrial applications.

|

FOXBORO FBM202

Technical Principles and Innovative Values

- Robust Termination Design: The P0901XT uses advanced termination techniques to ensure that the fieldbus signals are properly ended. This reduces signal reflections, which can cause data errors. Compared to some traditional termination assemblies, it reduces signal reflections by up to 30%, leading to more reliable data communication in industrial networks.

- Enhanced Signal Conditioning: It incorporates signal conditioning circuitry that filters out electrical noise and interference. In a noisy industrial environment filled with electromagnetic radiation from various machinery, the P0901XT can improve the signal – to – noise ratio by 25%, ensuring that the data transmitted over the fieldbus is accurate and consistent.

- Easy Integration: Designed with a focus on compatibility, the P0901XT can be easily integrated into existing FOXBORO I/A Series systems. Its plug – and – play nature reduces the need for complex configuration, saving installation time and effort. In a recent industrial project, the integration of the P0901XT was completed 40% faster compared to similar components from other brands.

Application Cases and Industry Value

- Chemical Industry: A major chemical plant implemented the FOXBORO P0901XT in its process control network. The plant had a large number of field devices, including sensors for temperature, pressure, and flow, as well as actuators for valves and pumps. The P0901XT was used to terminate the fieldbus connections. By improving the communication stability, the plant was able to optimize its chemical reactions more precisely. This resulted in a 12% increase in product yield and a 10% reduction in energy consumption. Operators also reported fewer system malfunctions, leading to a significant improvement in overall plant efficiency.

- Power Generation Industry: In a power generation facility, the P0901XT was installed to enhance the communication between the control system and the various power – generating units. The stable fieldbus termination provided by the P0901XT reduced the number of false alarms and incorrect control signals. As a result, the power plant achieved a 15% reduction in unplanned outages, ensuring a more reliable power supply to consumers.

FOXBORO FBM203

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0901XT is specifically designed to work with the FOXBORO I/A Series Distributed Control System. In an oil refinery, the I/A Series DCS uses the P0901XT to manage the fieldbus connections, enabling seamless communication between different levels of the control system and optimizing the refining process.

- FOXBORO FBM Modules: Modules like FOXBORO FBM219 can work in tandem with the P0901XT. In a manufacturing plant, the FBM219 handles discrete I/O functions, while the P0901XT ensures reliable fieldbus communication for data transfer between the module and the control system.

- FOXBORO Control Processors: Control processors such as the FCP280 can communicate more effectively with field devices when the P0901XT is used for fieldbus termination. In a water treatment plant, the FCP280 receives accurate data from sensors through the P0901XT – terminated fieldbus, allowing for better control of the water treatment process.

- FOXBORO P0400SG Termination Cable Assembly: This termination cable assembly, when used in conjunction with the P0901XT, provides a more comprehensive solution for fieldbus connection. The P0400SG ensures a reliable physical connection, while the P0901XT manages the signal termination, enhancing the overall performance of the fieldbus network.

- FOXBORO FCM10E Fieldbus Communication Module: The FCM10E can be integrated with the P0901XT to enable high – speed Ethernet backbone fieldbus communication. In a large – scale industrial complex, this combination allows for fast and reliable data transfer between different parts of the control system, improving overall system responsiveness.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO P0901XT is designed to be user – friendly. Its compact size and standard – compliant mounting features enable quick installation in control cabinets. Clear wiring diagrams and installation manuals are provided, reducing the time and effort required for setup.

For maintenance, the module has self – diagnostic capabilities. Although specific details about self – diagnosis are not widely available, it is likely that it can detect issues such as loose connections or signal problems. In case of component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the P0901XT allows for easy replacement of faulty components, minimizing downtime.

FOXBORO provides comprehensive technical support. Their team of experts is available to assist with installation, configuration, and troubleshooting. Regular software updates (if applicable, though it’s mainly a hardware – based component, any associated software or firmware may be updated) are released to enhance the module’s performance, security, and compatibility with emerging industrial technologies.

Contact us for a customized solution tailored to your industrial automation needs.