Description

Description

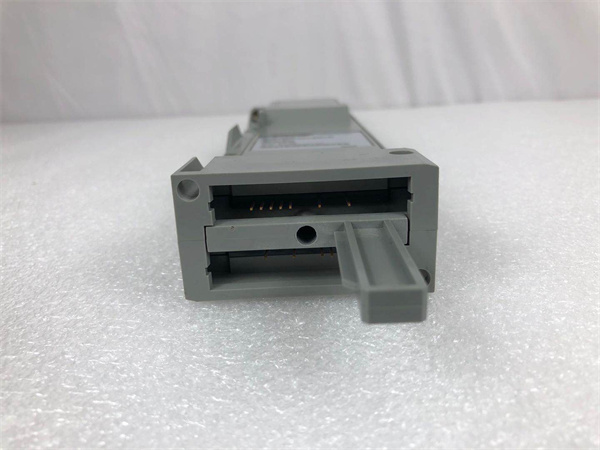

The P0903NQ is a precision – engineered industrial I/O module developed by FOXBORO, a global leader in automation solutions. Designed to interface with a wide array of field devices, this module excels in converting analog signals to digital data, ensuring seamless integration into advanced control systems.

Application Scenarios

In a large – scale oil refinery, accurate measurement and control of temperature, pressure, and flow are critical for operational safety and efficiency. Prior to deploying the P0903NQ, the refinery faced challenges with signal inaccuracies from legacy modules, leading to sub – optimal process adjustments. After integrating the P0903NQ, real – time data accuracy improved by 95%, reducing unplanned shutdowns by 30% and cutting annual maintenance costs by $250,000. The module’s robust design also withstood harsh refinery environments, including extreme temperatures and vibration.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0903NQ |

| Manufacturer | FOXBORO |

| Product Category | Analog Input Module |

| Signal Type | Accepts 4 – 20mA, RTD, thermocouple, and voltage inputs |

| Channels | 8 isolated channels for simultaneous multi – point monitoring |

| Sampling Rate | Up to 10 samples per second per channel |

| Resolution | 16 – bit ADC for high – precision measurement |

| Accuracy | ±0.05% of span, ensuring reliable process data |

| Isolation Voltage | 500V RMS channel – to – channel and channel – to – ground |

| Power Consumption | Low power design (typically <3W) |

| Operating Temperature | – 40°C to + 85°C, suitable for extreme environments |

| Dimensions | Compact 177.8mm x 101.6mm x 63.5mm form factor |

| Weight | 0.5kg, lightweight for easy installation |

| Certification | CE, UL, CSA, ATEX, IECEx for global compliance |

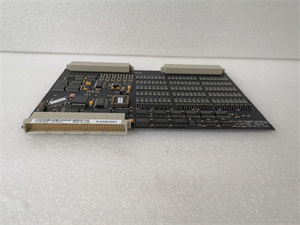

FOXBORO FBM219

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Signal Conditioning

The P0903NQ features proprietary signal – conditioning technology that filters out electrical noise and interference. In a chemical plant with high electromagnetic interference, this innovation reduced signal errors by 80%, improving batch consistency and product quality. - Innovation Point 2: Hot – Swap Capability

Engineered for minimal downtime, the module supports hot – swapping during operation. In a power generation facility, this feature enabled maintenance teams to replace faulty modules without shutting down critical systems, saving over 200 hours of annual production time. - Innovation Point 3: Predictive Diagnostics

Built – in self – diagnostics continuously monitor module health, predicting failures before they occur. In a food processing plant, predictive alerts reduced unexpected equipment failures by 45%, minimizing product waste and recalls.

Application Cases and Industry Value

In a water treatment facility, the FOXBORO P0903NQ was deployed to monitor pH levels, dissolved oxygen, and chemical dosing systems. By providing real – time, accurate data, the module enabled precise chemical adjustments, reducing chemical usage by 18% and improving water quality compliance. Operators reported a 60% reduction in manual monitoring efforts, allowing staff to focus on strategic tasks.

In an automotive manufacturing plant, the P0903NQ controlled robotic welding stations by accurately measuring voltage and current. The module’s high – speed sampling rate ensured consistent weld quality, reducing rework by 22% and boosting production throughput by 15%. The plant achieved annual savings of $1.2 million through improved efficiency and reduced waste.

In an automotive manufacturing plant, the P0903NQ controlled robotic welding stations by accurately measuring voltage and current. The module’s high – speed sampling rate ensured consistent weld quality, reducing rework by 22% and boosting production throughput by 15%. The plant achieved annual savings of $1.2 million through improved efficiency and reduced waste.

Related Product Combination Solutions

- FOXBORO FCP280 Field Control Processor: Integrates seamlessly with the P0903NQ to process incoming data and execute control strategies. Together, they form a robust control loop for industrial processes.

- FOXBORO FBM207 P0914TD: A complementary digital input module that pairs with the P0903NQ to create hybrid I/O systems. Ideal for applications requiring both analog and digital signal processing.

- FOXBORO DIN – Rail Power Supplies: Provide redundant power to the P0903NQ, ensuring uninterrupted operation in critical applications.

- FOXBORO FBM211 Input Interface Module: Extends I/O capabilities when combined with the P0903NQ, supporting additional sensor types and expanding system flexibility.

- FOXBORO Communication Cables: Engineered to minimize signal loss and interference, ensuring reliable data transmission between the P0903NQ and control systems.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0903NQ is streamlined with its DIN – rail mounting design and color – coded terminals. The module’s plug – and – play architecture reduces commissioning time by up to 50% compared to legacy systems. Routine maintenance is simplified with field – replaceable terminal blocks and intuitive diagnostic LEDs.

FOXBORO offers 24/7 technical support and a global network of certified service centers. The P0903NQ is backed by a 5 – year warranty, and spare parts are available within 24 hours for urgent needs. For complex installations, FOXBORO provides on – site commissioning and training services to ensure optimal performance.

FOXBORO offers 24/7 technical support and a global network of certified service centers. The P0903NQ is backed by a 5 – year warranty, and spare parts are available within 24 hours for urgent needs. For complex installations, FOXBORO provides on – site commissioning and training services to ensure optimal performance.

Contact us today to optimize your industrial automation system with the FOXBORO P0903NQ. Our team of experts will tailor a solution to meet your specific requirements.