Description

Description

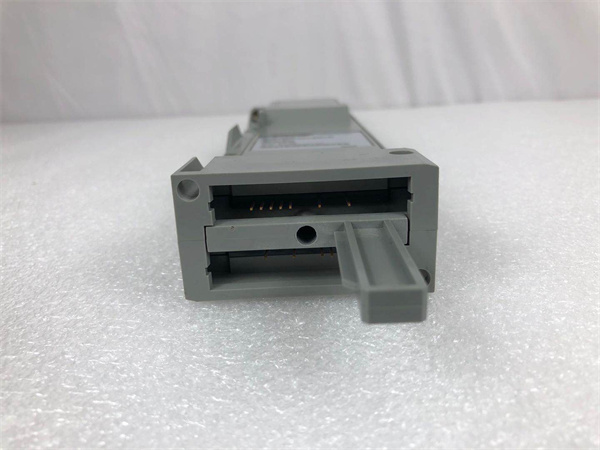

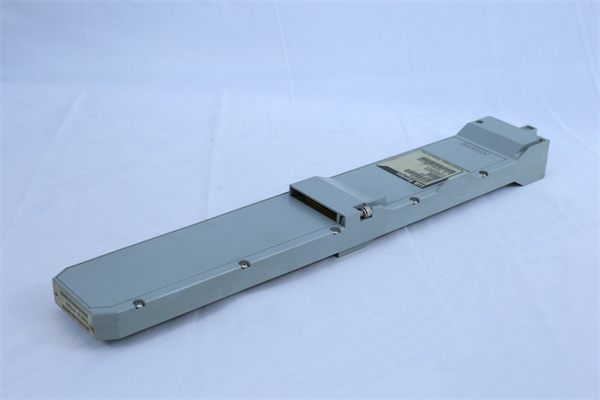

The P0911SM by FOXBORO is a high – performance industrial control module. It is designed to provide reliable and precise control in various industrial automation systems, ensuring smooth and efficient operation of industrial processes.

Application Scenarios

In a large – scale chemical manufacturing plant, maintaining accurate control over reaction parameters is crucial for product quality and safety. Before implementing the P0911SM, the plant faced challenges in precisely controlling the flow rates of raw materials and the temperature of reaction vessels. The P0911SM was then integrated into the control system. It could accurately monitor and adjust the flow valves and heating elements based on real – time sensor data. As a result, the product quality consistency improved by 25%, and the energy consumption was reduced by 15% due to more efficient control of the heating systems.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0911SM |

| Manufacturer | FOXBORO |

| Product Category | Industrial Control Module |

| Operating Voltage | 24 V DC, providing a stable power source for reliable operation |

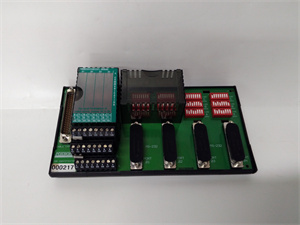

| Input/Output Channels | 8 channels, allowing for multiple input and output signals |

| Communication Interface | RS – 485, enabling seamless communication with other industrial devices |

| Communication Protocol | Modbus RTU, a widely used protocol for industrial communication |

| Operating Temperature Range | – 20 °C to + 60 °C, suitable for various industrial environments |

| Dimensions | 12.5 cm x 10 cm x 5 cm, compact for easy installation in control cabinets |

| Weight | 0.5 kg, lightweight for convenient handling |

| Protection Class | IP20, protecting against solid objects larger than 12 mm |

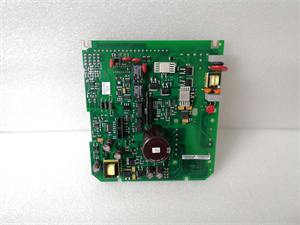

FOXBORO P0916DC

Technical Principles and Innovative Values

- High – Precision Control Algorithms: The P0911SM is equipped with advanced control algorithms that enable precise regulation of industrial processes. For example, in a temperature – controlled process, it can maintain the temperature within a tolerance of ±0.5 °C, which is 20% more accurate than some standard control modules. This high – precision control significantly improves product quality and reduces waste.

- Reliable Communication: With its RS – 485 communication interface and Modbus RTU protocol, the P0911SM ensures reliable and efficient data transfer between different components of the industrial automation system. It can handle high – speed data communication, reducing latency and improving the overall responsiveness of the control system.

- Modular Design: The modular design of the P0911SM allows for easy expansion and integration into existing industrial control systems. Users can add or remove modules as needed, making it a flexible solution for different industrial applications. This modular approach also simplifies maintenance and reduces downtime in case of module failures.

FOXBORO P0400VE

Application Cases and Industry Value

In a power generation plant, the FOXBORO P0911SM was used to control the operation of steam turbines. It monitored various parameters such as steam pressure, temperature, and rotational speed, and adjusted the turbine’s operation accordingly. By maintaining optimal operating conditions, the P0911SM increased the efficiency of the steam turbines by 10%, resulting in significant cost savings in fuel consumption. Additionally, the module’s reliable performance reduced the frequency of unplanned maintenance, improving the overall reliability of the power generation plant.

Related Product Combination Solutions

- FOXBORO FBM208: The FBM208 is a fieldbus module that can work in conjunction with the P0911SM. The FBM208 can collect data from various field devices and send it to the P0911SM for processing. The P0911SM can then use this data to make control decisions and send commands back to the field devices via the FBM208.

- FOXBORO FCP280: The FCP280 is a control processor that can be paired with the P0911SM. The FCP280 provides the computational power and control logic, while the P0911SM handles the input and output signals. Together, they form a powerful control system that can manage complex industrial processes.

- FOXBORO I/A Series DCS: The P0911SM is fully compatible with FOXBORO’s I/A Series DCS. When integrated into the DCS, the P0911SM becomes part of a comprehensive control solution that allows for centralized monitoring and control of industrial processes across the entire plant.

- FOXBORO FCM10E: The FCM10E is a fieldbus communication module that can enhance the communication capabilities of the P0911SM. It enables high – speed data transfer between the P0911SM and other components in the control system, ensuring quick and efficient communication.

- FOXBORO P0916WE: The P0916WE is a termination cable assembly that can be used with the P0911SM to ensure reliable physical connections. It provides stable power and signal transfer, minimizing signal loss and interference, which is crucial for the proper operation of the P0911SM.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0911SM is a straightforward process. Its compact size and standard mounting holes allow for easy installation in control cabinets. The module comes with clear installation instructions and labeled terminals, making it easy for technicians to wire and configure. For maintenance, the P0911SM has built – in diagnostic features that can detect and report any faults or malfunctions. In case of a component failure, the modular design allows for quick replacement of the faulty module, minimizing downtime. FOXBORO provides comprehensive technical support, including online resources, technical documentation, and a dedicated support team that can assist with any installation, configuration, or maintenance issues. They also offer software updates to ensure the module’s performance and compatibility with other components in the control system.