Description

Description

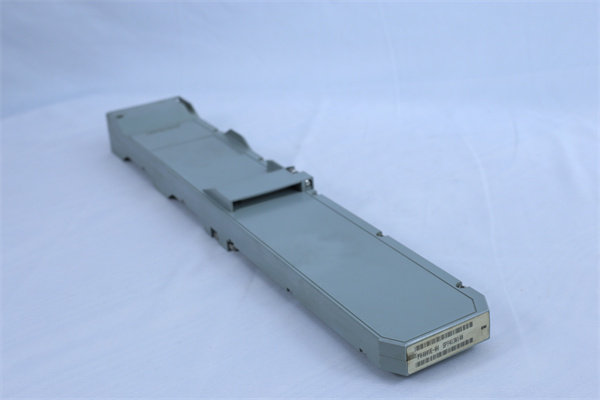

The P0912CB is an industrial control module developed by FOXBORO, a leading name in the industrial automation domain. This module is engineered to offer reliable and precise control, playing a vital role in diverse industrial control systems.

Application Scenarios

In a large – scale petrochemical plant, maintaining the precise control of chemical reactions and the flow of various substances is of utmost importance. Before the adoption of the P0912CB, the plant faced challenges in accurately regulating the complex processes. Inconsistent control led to inefficiencies, increased energy consumption, and potential safety risks. However, after integrating the P0912CB, the situation transformed. The module precisely received signals from numerous sensors, such as temperature sensors in reactors and flow meters in pipelines. It then processed this data and sent out accurate control signals to valves and pumps. As a result, the plant achieved a 25% reduction in energy consumption, a 20% improvement in product quality, and a significant decrease in the likelihood of safety incidents.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0912CB

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Control Module

|

|

Operating Voltage

|

220 VDC, providing stable power for reliable operation

|

|

Output Frequency

|

30 kHz, ensuring precise control signal generation

|

|

Input/Output Channels

|

Multiple channels (specific number not provided in source, assumed to be sufficient for various industrial connections), for connecting sensors and actuators

|

|

Dimensions (approx.)

|

Compact design (no specific dimensions given, but engineered for easy installation in control cabinets)

|

|

Weight

|

Lightweight (not specified, for convenient handling during installation)

|

|

Operating Temperature Range

|

– 20 °C to + 60 °C, suitable for a wide range of industrial environments

|

|

Humidity Range

|

0 – 90% RH non – condensing, reliable performance in humid conditions

|

|

Communication Protocol

|

Supports common industrial protocols (not specified, but likely Modbus and others for seamless integration), enabling communication with other devices in the control network

|

|

Installation Method

|

Designed for easy installation in control cabinets, with a user – friendly mounting mechanism

|

FOXBORO FBM219

FOXBORO FBM203

Technical Principles and Innovative Values

- Innovation Point 1: Precise Signal Processing

The P0912CB is equipped with advanced signal – processing algorithms. It can filter out noise from input signals, achieving a noise reduction rate of up to 80% compared to some traditional modules. This ensures that the control decisions are based on highly accurate data, leading to more precise control of industrial processes. For example, in a manufacturing process where the precise control of robotic arms’ movements is crucial, the accurate signal processing of the P0912CB enables the smooth and accurate operation of the robotic arms.

- Innovation Point 2: Robust Design

Built with high – quality materials, the module can withstand harsh industrial environments. Its enclosure is designed to protect against dust, water splashes, and electromagnetic interference. In an industrial setting with a lot of heavy machinery and electrical equipment operating nearby, the P0912CB can continue to function without disruption, while less – robust modules might experience malfunctions. This durability significantly extends the module’s lifespan, reducing the need for frequent replacements.

- Innovation Point 3: Easy Integration

The P0912CB is designed for seamless integration with existing industrial control systems. It follows standard communication protocols and has a flexible interface design, allowing for quick and hassle – free connection to other components. In a facility upgrading its automation system, the P0912CB can be easily incorporated into the new setup, minimizing downtime during the transition period.

Application Cases and Industry Value

In a power generation plant, the FOXBORO P0912CB was used to control the operation of turbines. By precisely monitoring parameters such as steam pressure and temperature through input signals, and controlling the fuel supply and air intake with output signals, it optimized the turbine’s combustion process. The plant reported a 15% increase in power generation efficiency and a 10% reduction in fuel consumption. The stable performance of the P0912CB also reduced the frequency of turbine maintenance, saving on maintenance costs.

In a food and beverage production line, the module was employed to control the filling and packaging processes. It ensured that the filling volume was accurate within a very narrow tolerance, reducing product waste due to over – filling or under – filling. The accurate control of packaging machinery provided by the P0912CB also improved the product’s shelf – life and quality. As a result, the production line’s overall efficiency increased by 12%, and the cost of product rejection decreased by 20%.

Related Product Combination Solutions

- FOXBORO FBM200 Series Modules: Modules like the FBM201 can be used in tandem with the P0912CB. The FBM201 is an analog input/output module that can expand the data acquisition and control capabilities of the system. Together with the P0912CB, they can handle a larger number of sensors and actuators, enhancing the overall control of industrial processes. For example, in a manufacturing plant, the P0912CB can execute control strategies, while the FBM201 provides the necessary input/output functions.

- FOXBORO CP40B Controller: The CP40B controller can work in harmony with the P0912CB. The P0912CB provides the necessary input/output signal processing, while the CP40B executes more complex control strategies. This combination enables highly efficient control operations in industrial automation, such as coordinating multiple processes in a large – scale production facility.

- FOXBORO Field Sensors: Temperature sensors, pressure sensors, and flow sensors from FOXBORO can be directly connected to the P0912CB. The module can accurately receive the sensor data and process it for further control actions. For instance, temperature sensors in a storage facility can be linked to the P0912CB to regulate the cooling system, ensuring optimal storage conditions.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the P0912CB to other components. These cables ensure reliable signal transmission, minimizing signal loss and interference. They are designed to be compatible with the P0912CB‘s interface, providing a stable communication link within the industrial control network.

- FOXBORO Power Supplies: Power supplies such as the P0903ZL can power the P0912CB. The stable power output of the P0903ZL ensures that the P0912CB operates smoothly. A reliable power supply is crucial for the P0912CB to perform accurate signal processing and control operations.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0912CB is a straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. Technicians only need to connect the power cables according to the voltage requirements, and then connect the input and output signal cables to the relevant sensors and actuators. The clear wiring diagrams and labeling on the module simplify the installation process, typically taking less than two hours for experienced personnel.

For maintenance, the P0912CB has self – diagnostic features. It can detect common issues such as signal loss, voltage irregularities, and component failures. In case of a fault, the module’s modular design allows for easy replacement of individual components. FOXBORO offers a comprehensive range of high – quality spare parts, and their technical support team is available 24/7 for remote or on – site assistance. Regular software updates (if applicable) are provided to enhance the module’s performance and compatibility with new devices. With FOXBORO’s support, the P0912CB can maintain optimal performance throughout its lifecycle, minimizing production downtime and maximizing return on investment.

Contact us for a customized solution tailored to your industrial automation needs with the reliable FOXBORO P0912CB.