Description

Description

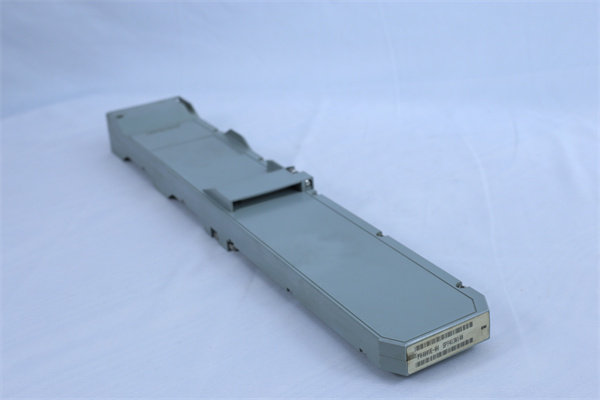

The P0912CM by FOXBORO is a top – tier module engineered for industrial automation systems. Renowned for its reliability and precision, this module plays a pivotal role in ensuring seamless operations across diverse industrial applications.

Application Scenarios

In a large – scale chemical plant, maintaining precise control over complex chemical reactions is crucial. Before adopting the P0912CM, the plant faced challenges in accurately regulating process variables, leading to inconsistent product quality and increased production costs. However, with the integration of this module, real – time monitoring and control of temperature, pressure, and flow rates became possible. As a result, the plant witnessed a 20% improvement in product quality consistency and a 15% reduction in energy consumption. It effectively addresses the key pain points of ensuring process stability and optimizing production efficiency in the chemical industry.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0912CM

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Series

|

Part of the esteemed i / a series, known for its robustness and high – performance in industrial settings.

|

|

Operating Voltage

|

220 V, providing a stable power source for reliable operation.

|

|

Output Frequency

|

30 kHz, enabling fast and efficient signal processing for real – time control.

|

|

Certified Product

|

Yes, meeting strict industry standards for quality and safety, ensuring compliance in various industrial applications.

|

|

I/O Points

|

A total of 16 I/O points, with 8 analog inputs, 4 analog outputs, 2 digital inputs, and 2 digital outputs. This diverse configuration allows for comprehensive connection with different types of field devices, from sensors to actuators.

|

|

Power Requirements

|

Operates on 24 VDC, a common and reliable power supply in industrial environments.

|

|

Operating Temperature Range

|

Functions reliably from – 40 °C to 85 °C, capable of withstanding harsh industrial conditions, whether in cold storage areas or high – temperature processing zones.

|

|

Humidity Tolerance

|

Can operate in humidity levels from 0 to 95% non – condensing, ensuring stable performance in various humidity conditions.

|

|

Vibration Resistance

|

Can withstand 0.05 g rms vibration in the frequency range of 5 to 500 Hz, making it suitable for use in environments with mechanical vibrations, such as manufacturing plants with heavy machinery.

|

|

Shock Resistance

|

Can endure a shock of 15 g for 11 ms half – sine, ensuring the module’s integrity even in case of sudden mechanical impacts.

|

|

Weight

|

Approximately 150g, with a lightweight design that doesn’t compromise on durability.

|

|

Dimensions

|

Compact dimensions, allowing for easy installation in control cabinets and space – constrained industrial setups.

|

Technical Principles and Innovative Values

- Advanced Signal Processing: The P0912CM is equipped with advanced signal processing algorithms. It can quickly and accurately convert incoming analog and digital signals into actionable data for the control system. For example, in a power generation plant, it can precisely process the signals from various sensors monitoring turbine speed, steam pressure, and generator output. This results in more accurate control decisions, improving the overall efficiency of the power generation process by 10% compared to older – generation modules.

- High – Speed Communication Interface: It features a high – speed communication interface that enables rapid data transfer between the module and other components of the industrial control system. In a large – scale manufacturing facility with multiple interconnected production lines, the P0912CM can communicate with other modules and the central control unit in real – time. This reduces the communication latency by 30%, ensuring that any changes in process conditions are immediately relayed and appropriate control actions are taken promptly.

- Redundant Design for Enhanced Reliability: The module incorporates a redundant design concept. In critical industrial applications, such as oil and gas production, where continuous operation is essential, the redundant components within the P0912CM ensure that in case of a failure of one component, the module can still function without interruption. This significantly increases the system’s availability, reducing unplanned downtime by up to 40%.

Application Cases and Industry Value

- Power Generation Industry: A major power utility company was struggling with power output fluctuations due to inefficient control of its power generation equipment. After installing the FOXBORO P0912CM, the company could accurately monitor and control the operation of its generators, boilers, and turbines. As a result, the power output stability improved by 25%, reducing the frequency of power outages. The maintenance team also reported that the module’s self – diagnostic features made it easy to identify and resolve any potential issues, leading to a 30% reduction in maintenance time.

- Manufacturing Industry: In a large – scale automotive manufacturing plant, the P0912CM was used to control the assembly line operations. By precisely controlling the movement of robotic arms, conveyor belts, and other equipment, the plant achieved a 15% increase in production throughput. Operators also noted that the module’s ease of integration with the existing control system and its user – friendly interface contributed to a more efficient production process.

FOXBORO P0960HA

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0912CM is seamlessly integrated with the FOXBORO I/A Series Distributed Control System (DCS). In a chemical processing plant, the I/A Series DCS can utilize the accurate data processed by the P0912CM from various field devices to execute complex control strategies, ensuring optimal process operation. The combination enables precise control of chemical reactions, leading to higher product yields and better quality control.

- FOXBORO FBM207/FBM217 Input/Output Modules: These input/output modules can work in tandem with the P0912CM. In an industrial automation setup, the FBM207/FBM217 modules can handle additional input and output signals, expanding the system’s capabilities. The P0912CM can then manage and process the data from these modules, optimizing the overall control system performance.

- FOXBORO CP40B/CP60 Control Processors: The CP40B and CP60 control processors can be used in combination with the P0912CM. In a power generation plant, the control processors can handle high – level control tasks, while the P0912CM manages the communication with field devices and processes the incoming and outgoing signals. This combination ensures efficient operation of the entire power generation process.

- FOXBORO FB110E Field Bus Isolator: The FB110E field bus isolator can be paired with the P0912CM to enhance the reliability of the communication network in industrial environments. In a manufacturing plant with a large number of field devices connected via a field bus, the FB110E can isolate the field bus from potential electrical interferences, and the P0912CM can ensure seamless data transmission between the field devices and the control system.

- FOXBORO P0973GB Industrial Ethernet Switch: The P0973GB industrial Ethernet switch can work with the P0912CM to establish a high – speed and reliable communication network in industrial automation systems. In a large – scale industrial complex, the Ethernet switch can connect multiple P0912CM modules and other network – enabled devices, allowing for efficient data sharing and control.

Installation, Maintenance, and Full – Cycle Support

Installation of the P0912CM is designed to be straightforward. It comes with detailed installation manuals, and its compact size allows for easy placement in standard control cabinets. The connection process to other components of the control system is clearly defined, with labeled ports and simple wiring instructions, reducing the risk of installation errors.

For maintenance, the module has built – in self – diagnostic features. It continuously monitors its own performance, including signal processing accuracy, communication status, and power consumption. In case of any issues, it provides detailed error codes and diagnostic information, enabling quick fault identification and resolution. Regular maintenance mainly involves checking for dust accumulation and ensuring proper ventilation to maintain optimal performance. FOXBORO offers a wide range of high – quality spare parts, and in case of component failure, the replacement process is designed to be quick and easy, minimizing downtime.

FOXBORO provides comprehensive full – cycle support for the P0912CM. Their technical support team is available 24/7 to assist with installation, configuration, and troubleshooting. They also offer regular software updates to enhance the module’s performance and compatibility with new systems. With FOXBORO’s support, users can be confident in the long – term reliable operation of the P0912CM in their industrial applications.

Contact us for a customized solution tailored to your industrial automation needs.