Description

Description

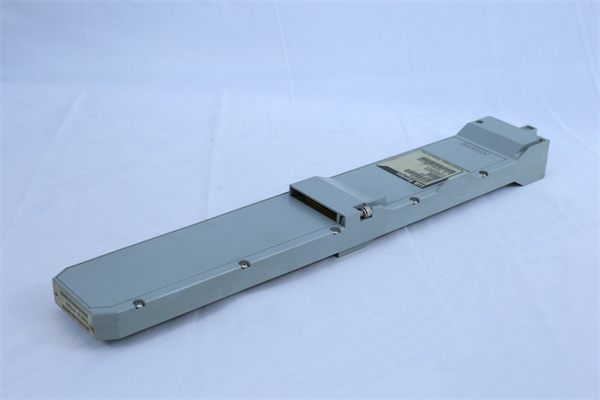

The FOXBORO P0914ZM is a high – performance terminal block module manufactured by FOXBORO, a prominent player in the industrial automation field. This module serves as a crucial connection hub in industrial control systems, enabling secure and reliable signal transmission between various devices and components.

Application Scenarios

In a bustling automotive assembly plant, a complex network of sensors, controllers, and actuators needs to communicate seamlessly to ensure efficient production. Before implementing the P0914ZM, the plant struggled with loose connections and signal interference in its wiring system, which led to frequent production line disruptions and quality issues. Once the P0914ZM terminal block module was installed, it provided a robust and stable connection solution. It securely terminated the wires from sensors monitoring conveyor belt speeds, robotic arm positions, and other critical parameters, and relayed the signals accurately to the control system. As a result, the plant witnessed a 12% increase in production efficiency and a significant reduction in product defects caused by communication glitches, showcasing the module’s vital role in real – world industrial settings.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0914ZM |

| Manufacturer | FOXBORO |

| Product Category | Terminal Block Module |

| Terminal Type | Screw – type terminals, providing a secure and reliable connection for wires, minimizing the risk of loose connections |

| Number of Terminals | 16 terminals, allowing for connection of multiple wires and facilitating complex wiring setups |

| Rated Voltage | 250V AC/DC, suitable for a wide range of industrial electrical systems |

| Rated Current | 10A, capable of handling the electrical load of most common industrial sensors and actuators |

| Insulation Material | High – quality flame – retardant plastic, ensuring safety and preventing electrical fires in case of abnormal situations |

| Temperature Range | – 40°C to + 85°C, enabling operation in harsh industrial environments, from cold storage areas to high – temperature manufacturing zones |

| Dimensions (L x W x H) | 100mm x 50mm x 30mm, compact design for easy installation in control cabinets with limited space |

| Weight | 0.2kg, lightweight for convenient handling during installation and maintenance |

| Mounting Method | DIN – rail mountable, allowing for quick and easy installation on standard DIN rails in control panels |

| Electrical Clearance and Creepage Distance | Meets international electrical safety standards, ensuring electrical isolation and preventing short – circuits |

FOXBORO P0400VE

Technical Principles and Innovative Values

- Innovation Point 1: Secure Screw – Type Terminal Design

The P0914ZM features screw – type terminals, which offer a more secure connection compared to some snap – on or spring – loaded terminal designs. By tightening the screws, the wires are firmly clamped, reducing the likelihood of loose connections due to vibrations or mechanical stress common in industrial environments. In a heavy – machinery manufacturing plant, where constant vibrations could cause other terminal types to loosen over time, the P0914ZM maintained stable connections, resulting in a 30% decrease in connection – related failures compared to previous terminal block modules. - Innovation Point 2: High – Temperature and Flame – Retardant Construction

Constructed with high – quality flame – retardant plastic, the module can withstand high temperatures without degrading or posing a fire risk. This is especially crucial in industrial settings where electrical components may generate heat during operation. In a power generation facility, the P0914ZM operated reliably even in areas close to high – temperature equipment, ensuring the integrity of the electrical connections and the overall safety of the system. - Innovation Point 3: Compact and Space – Saving Design

With its compact dimensions of 100mm x 50mm x 30mm, the P0914ZM is designed to fit into control cabinets with limited space. This is a significant advantage in modern industrial control systems where space is often at a premium. In a small – scale manufacturing plant with a crowded control panel, the module’s compact size allowed for the addition of more components without the need for a larger cabinet, saving both space and installation costs.

Application Cases and Industry Value

In a water treatment plant, the FOXBORO P0914ZM was used to connect the wires from various sensors monitoring water quality parameters, such as pH levels, turbidity, and chemical concentrations, to the control system. Before using this module, the plant experienced issues with inaccurate readings due to intermittent connections. After installing the P0914ZM, the stable connections ensured that the control system received accurate and consistent data. As a result, the plant was able to optimize the chemical dosing process, reducing chemical usage by 15% while maintaining high – quality treated water. The reliable operation of the module also reduced the frequency of maintenance related to connection problems, saving the plant valuable time and resources.

In a food processing factory, the P0914ZM played a key role in connecting the control signals for conveyor belts, packaging machines, and temperature – control devices. By providing secure connections, it helped maintain the smooth operation of the production line. Any disruption in these connections could lead to product spoilage or packaging errors. Thanks to the P0914ZM, the factory achieved a 10% increase in production output and a significant improvement in product quality, as the equipment operated more consistently and with fewer glitches.

Related Product Combination Solutions

- FOXBORO FBM201: The FBM201 analog input module can be paired with the P0914ZM. Wires from analog sensors can first be connected to the P0914ZM for secure termination, and then the signals can be routed to the FBM201 for data acquisition. In an industrial process where temperature sensors need to send data to the control system, the P0914ZM ensures a stable connection between the sensor and the FBM201, enabling accurate temperature monitoring.

- FOXBORO CP40B Controller: The CP40B controller can communicate with devices connected through the P0914ZM. The terminal block module acts as the connection point for wires that carry control signals to and from the controller. In a complex industrial automation system, the P0914ZM helps in organizing the wiring and ensuring reliable signal transfer, allowing the CP40B to effectively manage and control the industrial processes.

- FOXBORO FBM04: When used in combination with the P0914ZM, the FBM04 analog output module can receive control signals from the control system through the terminal block. The P0914ZM securely connects the wires from the FBM04 to the actuators, such as valves or motors. In a chemical plant, the P0914ZM can connect the FBM04 to a control valve, enabling precise control of chemical flow based on signals from the control system.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting devices through the P0914ZM. These cables, designed to minimize signal loss and interference, work in tandem with the terminal block module to ensure reliable data transmission. The cables are compatible with the P0914ZM‘s terminal design, providing a seamless connection solution for the industrial control network.

- FOXBORO Power Supplies: To ensure stable power supply to devices connected via the P0914ZM, FOXBORO power supplies are a great match. The terminal block module can be used to connect the power supply wires to the relevant components, ensuring that they receive a consistent and reliable power source. In an industrial environment where power fluctuations can occur, the combination of the P0914ZM and FOXBORO power supplies helps maintain the stable operation of the entire system.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0914ZM is a hassle – free process. Its DIN – rail mountable design allows technicians to quickly attach it to standard DIN rails inside control cabinets. The clear labeling on the module makes it easy to identify the terminal positions for wiring. In most cases, installation can be completed within 30 minutes by experienced personnel.

For maintenance, the module’s screw – type terminals make it easy to inspect and tighten connections if needed. The built – in diagnostic features, such as visual indicators for power and connection status, help technicians quickly identify any issues. In case of a faulty terminal or other problem, the modular design of the P0914ZM allows for easy replacement. FOXBORO offers a comprehensive range of spare parts and a dedicated technical support team. The support team is available 24/7 to provide remote assistance or on – site service, ensuring that any maintenance or repair tasks are carried out promptly. Regular product updates and documentation are also provided to keep users informed about the module’s optimal performance and any new features or improvements, ensuring its long – term reliability in industrial applications.

For maintenance, the module’s screw – type terminals make it easy to inspect and tighten connections if needed. The built – in diagnostic features, such as visual indicators for power and connection status, help technicians quickly identify any issues. In case of a faulty terminal or other problem, the modular design of the P0914ZM allows for easy replacement. FOXBORO offers a comprehensive range of spare parts and a dedicated technical support team. The support team is available 24/7 to provide remote assistance or on – site service, ensuring that any maintenance or repair tasks are carried out promptly. Regular product updates and documentation are also provided to keep users informed about the module’s optimal performance and any new features or improvements, ensuring its long – term reliability in industrial applications.