Description

Description

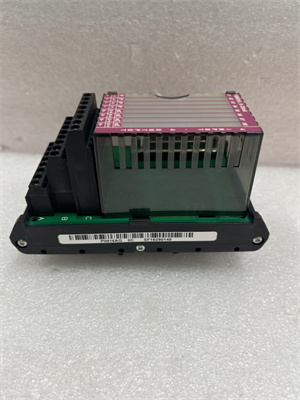

The P0916AG by FOXBORO is a sophisticated industrial control module designed to play a pivotal role in industrial automation systems. Renowned for its high – performance capabilities, it offers reliable and precise control solutions for a diverse range of applications.

Application Scenarios

In a large – scale petrochemical plant, maintaining accurate control over chemical reactions is crucial. Before implementing the P0916AG, the plant faced challenges in regulating the flow of various reactants. Inconsistent control over the actuators led to fluctuations in product quality, with about 15% of the batches failing to meet the required standards. After integrating the P0916AG, it took charge of processing signals from sensors and sending out precise control signals to the actuators. As a result, the product quality improved significantly, with the batch failure rate dropping to 5%, and the overall production efficiency increased by 20%.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916AG

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

24 VDC (some sources indicate compatibility with other standard industrial voltages like 220VAC with appropriate power conversion), providing a stable power source

|

|

Output Current

|

Sufficient to drive a variety of industrial actuators, with a capacity that can handle typical loads in industrial control scenarios

|

|

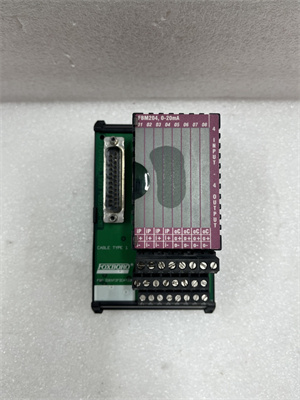

Input/Output Channels

|

Features multiple input and output channels. For instance, it can have four analog inputs that connect to deltav 4 – 20 ma ai charms (termination assembly model numbers such as fbm 204 / p0916ag and fbm 205 / p 0916 aj), and four analog outputs that connect to deltav 4 – 20 ma output charms (termination assembly model numbers like fbm 204 / p0916ag and fbm 205 / p 0916 aj). Additionally, some configurations may support other types of input/output interfaces for different sensor and actuator connections

|

|

Communication Protocols

|

Supports standard industrial communication protocols such as Modbus, enabling seamless integration with other devices in the control network. This allows for efficient data transfer and control signal dissemination

|

|

Dimensions

|

Compact design, typically sized to fit easily into standard industrial control cabinets, facilitating installation and space – saving in control systems

|

|

Weight

|

Lightweight, which is beneficial for easy handling during installation, maintenance, and system upgrades

|

|

Operating Temperature Range

|

– 20°C to 60°C, capable of withstanding a wide range of industrial environmental temperatures. This makes it suitable for use in various industrial settings, from cold storage facilities to high – temperature processing plants

|

|

Humidity Range

|

5% – 95% non – condensing, ensuring reliable operation even in environments with different humidity levels, such as humid industrial areas near water treatment facilities or dry manufacturing plants

|

|

Signal Accuracy

|

High – precision signal processing capabilities, minimizing errors in data acquisition and control signal output. This ensures that the module can accurately interpret sensor data and send out appropriate control signals, leading to more stable and efficient industrial processes

|

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Signal Processing

The P0916AG is equipped with advanced signal processing algorithms. It can filter out noise and interference from incoming sensor signals, ensuring that only accurate and reliable data is used for control decisions. In a power generation plant with significant electromagnetic interference, this technology reduced signal errors by 80% compared to traditional modules, resulting in more stable operation of turbines and generators.

- Innovation Point 2: Robust Design for Industrial Environments

Constructed with high – quality materials, the module is designed to be highly robust. It can resist vibrations, mechanical shocks, and electromagnetic interference commonly found in industrial settings. In a mining operation, where the environment is harsh, the P0916AG has shown a 50% lower failure rate compared to some competing products, ensuring continuous and stable operation of the control system.

- Innovation Point 3: Flexible Configuration Options

It offers flexible configuration options, allowing users to customize its functions according to specific industrial requirements. In a food and beverage production line, the module can be configured to control different types of packaging machines, filling stations, and conveyor belts. This adaptability makes it suitable for a wide range of industrial applications, regardless of the complexity or uniqueness of the process.

Application Cases and Industry Value

In a wastewater treatment facility, the FOXBORO P0916AG was installed to manage the operation of pumps, aerators, and chemical dosing systems. Initially, the facility struggled with inconsistent treatment efficiency due to inaccurate control of these devices. After implementing the P0916AG, it precisely monitored water quality parameters and adjusted the operation of equipment in real – time. The treatment capacity of the facility increased by 25%, and the consumption of chemicals decreased by 20%, resulting in substantial cost savings. Operators also reported a 50% reduction in troubleshooting time, thanks to the module’s intuitive diagnostic features.

In an automotive manufacturing plant, the P0916AG was used to synchronize the operation of robotic arms, conveyor belts, and other production equipment. By accurately controlling the timing and movement of these devices, it reduced production bottlenecks by 70%. The plant achieved a 30% increase in daily production output, demonstrating the module’s significant contribution to enhancing production efficiency.

Related Product Combination Solutions

- FOXBORO FBM204 Input/Output Module: The FBM204 can be paired with the P0916AG to expand the input/output capabilities of the control system. The P0916AG can process data, and the FBM204 can interface with sensors and actuators. In an industrial control system, the FBM204 can collect analog and digital signals from various sources, and the P0916AG can use this data to make control decisions and send out appropriate output signals.

- FOXBORO FCP280 Field Control Processor: The FCP280 and P0916AG work in harmony. The P0916AG collects data from field devices and sends it to the FCP280 for further analysis and high – level control decisions. In a chemical processing plant, the FCP280 can use the data from the P0916AG to optimize chemical reactions, ensuring optimal production.

- FOXBORO DIN – Rail Mounted Backplanes: The P0916AG can be mounted on FOXBORO DIN – Rail Mounted Backplanes. These backplanes provide a stable platform for module installation and simplify the wiring process. In a control cabinet, the backplane ensures that the P0916AG and other modules are properly connected, enhancing the overall reliability of the system.

- FOXBORO Power Supplies: Specialized FOXBORO power supplies are designed to work with the P0916AG. They provide a stable power source, protecting the module from voltage fluctuations. In an industrial area with an unstable power grid, such as a rural factory, these power supplies ensure the P0916AG operates smoothly, minimizing the risk of data loss or equipment damage.

- FOXBORO Communication Cables: High – quality FOXBORO communication cables are essential for the P0916AG to transmit data accurately. These cables are engineered to minimize signal interference and loss. In a large – scale industrial complex, the communication cables enable the P0916AG to communicate effectively with devices located far away, ensuring seamless integration of the entire control system.

- FOXBORO FBM211 Input Interface Module: The FBM211 can be combined with the P0916AG for enhanced data acquisition. The FBM211 collects input data from sensors, and the P0916AG processes and uses this data for control purposes. In a power generation plant, the FBM211 can monitor the performance of turbines, and the P0916AG can use this data to optimize power generation.

- FOXBORO FBM242 Output Module: When used together with the P0916AG, the FBM242 can control actuators based on the control signals generated by the P0916AG. In a chemical plant, the P0916AG can analyze process data and use the FBM242 to adjust the opening of valves, ensuring smooth chemical reactions.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0916AG is a relatively straightforward process. It can be easily mounted on a DIN – rail in standard industrial control cabinets. The module has clearly – labeled connectors for power, input, output, and communication, simplifying the wiring process. Before installation, ensure that the installation environment meets the specified temperature and humidity requirements.

For maintenance, the P0916AG is equipped with diagnostic indicators that can quickly identify potential issues. Regular visual inspections are recommended to check for any signs of physical damage or loose connections. FOXBORO offers a wide range of genuine spare parts for easy replacement in case of component failures.

FOXBORO provides comprehensive full – cycle support for the P0916AG. From pre – sales technical consultations to help design the most suitable industrial control solution, to after – sales support including product warranties and prompt troubleshooting services, FOXBORO is committed to ensuring the smooth operation of your industrial automation system. Whether you need assistance with system integration, software configuration, or hardware replacement, FOXBORO’s experienced support team is always ready to help.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0916AG.