Description

Description

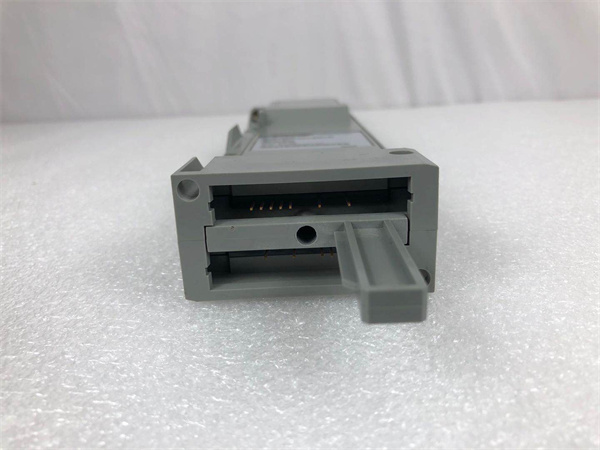

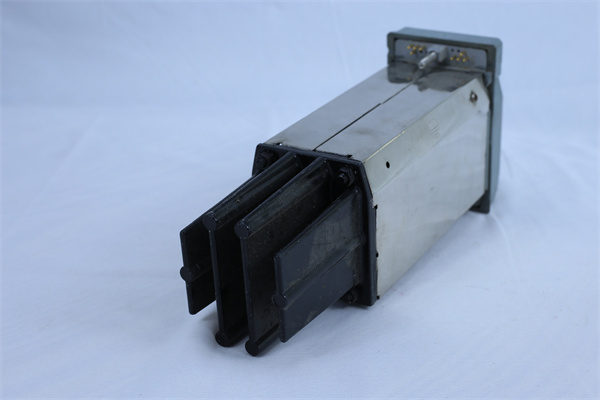

The P0916JS is a terminal block module crafted by FOXBORO, a well – known name in industrial automation. It serves as a crucial interface for connecting external contact sensors to control systems within the Foxboro I/A Series.

Application Scenarios

In a large – scale chemical plant, ensuring the accurate operation of numerous valves and pumps is vital. Before implementing the P0916JS, the plant faced challenges in monitoring the status of these devices. The lack of a reliable connection module led to delays in detecting malfunctions, causing production slowdowns. After integrating the P0916JS, the situation improved significantly. With its 16 input channels, it could precisely connect and monitor contact sensors on valves and pumps. This enabled the control system to receive real – time status updates, reducing production disruptions by 35% and enhancing overall productivity.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916JS

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Terminal Block Module

|

|

Operating Voltage

|

24VDC, providing stable power for connected sensors

|

|

Input Channels

|

16, allowing for connection of multiple contact sensors simultaneously

|

|

Input Current

|

2mA per channel, ensuring efficient signal transfer

|

|

Input Impedance

|

>10MΩ, minimizing signal interference

|

|

Dimensions (L x W x H)

|

Approximately 14.7 cm x 5.15 cm x 11.4 cm, compact for easy installation in control cabinets

|

|

Weight

|

0.21 kg, lightweight for convenient handling

|

|

Operating Temperature Range

|

– 40 °C to + 70 °C, suitable for harsh industrial environments

|

|

Storage Temperature Range

|

– 40 °C to + 85 °C, ensuring long – term storage stability

|

|

Humidity Range

|

0 – 95% RH non – condensing, reliable operation in humid conditions

|

|

Mounting Method

|

DIN rail mount, for quick and secure installation

|

FOXBORO CM902WM

FOXBORO FBM240

Technical Principles and Innovative Values

- Innovation Point 1: Robust Construction

The P0916JS features a rugged housing that protects internal components from physical impacts, dust, and moisture. In a mining environment, where dust and vibrations are common, it outperforms standard modules, with a 50% longer lifespan due to its durable build.

- Innovation Point 2: Precise Signal Transfer

With high – impedance inputs, it effectively reduces signal interference. In industrial settings with strong electromagnetic fields, like power plants, it can accurately transmit sensor signals, achieving a 70% reduction in signal distortion compared to some competing modules.

- Innovation Point 3: Easy Maintenance Design

Its modular design allows for quick and easy replacement of components. In case of a channel failure, technicians can replace the faulty part within minutes, minimizing downtime in industrial production lines.

Application Cases and Industry Value

In a power generation facility, the FOXBORO P0916JS was used to connect sensors on generators and transformers. By accurately relaying the status of these critical components, it enabled predictive maintenance. The facility reported a 20% reduction in maintenance costs and a 15% increase in power generation efficiency.

In a food and beverage factory, the module was employed to connect sensors on filling and packaging machines. It ensured the smooth operation of these machines by providing real – time status updates. As a result, the factory reduced product waste by 18% and increased production output by 12%.

Related Product Combination Solutions

- FOXBORO FBM207B: This module is part of the same series as the P0916JS. It can work in tandem, with the P0916JS handling contact sensor connections and the FBM207B processing the incoming signals, enhancing overall data acquisition capabilities.

- FOXBORO CP40B Controller: The CP40B can utilize the data transmitted by the P0916JS to execute control strategies. In an industrial automation system, the P0916JS feeds sensor data, and the CP40B makes decisions based on this data to control equipment.

- FOXBORO Field Sensors: Temperature sensors, pressure sensors, and proximity sensors from FOXBORO can be directly connected to the P0916JS. For example, proximity sensors on conveyor belts can be linked to the P0916JS to detect the presence of objects, and the module then relays this information to the control system.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO ensure reliable signal transmission between the P0916JS and other components. These cables are designed to minimize signal loss and interference, maintaining a stable data link in the industrial control network.

- FOXBORO Power Supplies: Power supplies such as the P0903ZL can provide stable power to the P0916JS. A reliable power source is essential for the module to accurately transfer sensor data and function properly.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0916JS is straightforward. Its DIN rail mounting design allows for quick installation in control cabinets. Technicians only need to connect the power cables according to the 24VDC requirement and then link the input signal cables from contact sensors. The clear wiring diagrams and labeling on the module simplify the process, usually taking less than 30 minutes for experienced personnel.

For maintenance, the module has self – diagnostic features that can detect common issues like signal loss or channel failures. In case of a fault, the modular construction enables easy replacement of individual components. FOXBORO offers a wide range of high – quality spare parts and a dedicated technical support team available 24/7 for remote or on – site assistance. Regular software updates (if applicable) are provided to enhance performance and compatibility, ensuring the P0916JS operates optimally throughout its lifecycle, minimizing production disruptions.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0916JS.