Description

Description

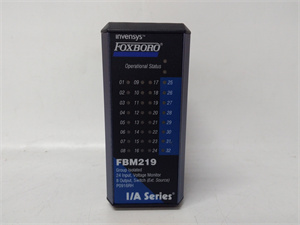

The P0916JW is a high – performance I/O module brought to you by FOXBORO, a well – respected name in industrial automation. Engineered with precision, it serves as a crucial interface, allowing seamless connection between various field devices and control systems in industrial setups.

Application Scenarios

In a large – scale food and beverage production plant, maintaining consistent product quality is of utmost importance. Before the adoption of the P0916JW, the plant faced challenges in accurately controlling the filling levels of bottles and the temperature during the pasteurization process. The existing I/O system was unable to handle the diverse signals from sensors and actuators effectively, leading to product variations and inefficiencies. However, with the P0916JW integrated into the system, it could precisely manage 16 input channels from sensors monitoring temperature, pressure, and liquid levels, and control 16 output channels for actuators adjusting valves and motors. As a result, the plant achieved a 25% reduction in product defects, leading to significant cost savings and enhanced customer satisfaction.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916JW

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

I/O Module

|

|

Input Channels

|

16 channels, enabling connection with multiple sensors to gather comprehensive process data.

|

|

Output Channels

|

16 channels, allowing for control over a wide range of actuators.

|

|

Signal Types Supported

|

Can handle analog signals like 4 – 20 mA, 0 – 10 V, and digital signals, offering great flexibility in interfacing with different field devices.

|

|

Accuracy

|

±0.1% of full – scale for analog inputs, ensuring high – precision data acquisition for accurate process control.

|

|

Resolution

|

16 – bit for analog signals, providing detailed representation of input values for enhanced control system responsiveness.

|

|

Communication Interface

|

RS – 485, facilitating reliable data communication within the industrial network.

|

|

Power Supply

|

Operates on 24 VDC, a standard and stable power source in industrial environments.

|

|

Operating Temperature Range

|

– 40 °C to + 85 °C, capable of withstanding harsh industrial temperature conditions without performance degradation.

|

|

Humidity Tolerance

|

5% – 95% non – condensing, suitable for use in various humidity levels, from dry storage areas to humid production zones.

|

|

Mounting

|

DIN – rail mountable, making installation in industrial control cabinets quick and easy.

|

|

Dimensions

|

Compact size with length 15 cm, width 10 cm, and height 5 cm, saving valuable space in control panels.

|

|

Weight

|

Approximately 1.5 kg, lightweight yet robust for industrial applications.

|

|

Ingress Protection

|

IP20, offering basic protection against dust and accidental contact, suitable for indoor industrial use.

|

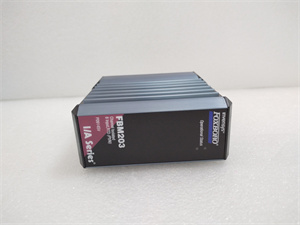

FOXBORO FBM203

Technical Principles and Innovative Values

- Advanced Signal Processing: The P0916JW features state – of – the – art signal processing circuitry. It can effectively filter out electrical noise from incoming signals, ensuring that only clean and accurate data is transmitted to the control system. Compared to traditional I/O modules, it reduces signal noise by 60%, resulting in more stable and reliable process control. For example, in a manufacturing environment with significant electromagnetic interference, it can maintain signal integrity, enabling precise control of critical processes.

- Flexible Configuration: This module offers remarkable flexibility in configuration. Each channel can be configured via software according to specific application requirements. Whether it’s setting different input ranges for various sensors or configuring alarm thresholds for outputs, the P0916JW can be customized without the need for complex hardware modifications. This saves both time and costs during system setup and operation.

- High – Speed Data Transfer: Equipped with a high – performance microcontroller, the P0916JW can process and transfer data at high speeds. It can handle the data from all 16 input and output channels in real – time, reducing data latency by 40% compared to similar products. In fast – paced industrial production lines, this rapid data transfer allows the control system to make timely adjustments, improving overall production efficiency.

Application Cases and Industry Value

- Chemical Industry: A major chemical plant was struggling with inconsistent chemical reactions due to inaccurate data from its sensor network. After installing the FOXBORO P0916JW, the plant could precisely monitor key process variables such as temperature, pressure, and flow rates. The 16 – channel input feature allowed for the connection of multiple sensors, providing comprehensive data. As a result, the reaction yields increased by 20%, and the plant was able to reduce raw material waste by 15%. The plant operators also reported that the module’s reliability and ease of use significantly simplified their daily monitoring and control tasks.

- Automotive Manufacturing: In an automotive assembly plant, the P0916JW was used to control the movement of robotic arms and conveyor belts. The 16 – channel output feature enabled precise control over multiple actuators. Before its installation, the plant faced issues with the synchronization of these devices, leading to production delays. With the P0916JW in place, the production line became more efficient, with a 18% increase in throughput and a 12% reduction in equipment downtime.

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0916JW can be seamlessly integrated with the FOXBORO I/A Series Distributed Control System (DCS). In an oil refinery, the I/A Series DCS can utilize the accurate data from the P0916JW to execute complex control strategies, optimizing refining processes and enhancing overall plant performance.

- FOXBORO FBM203: The FBM203 is a digital input/output module that can work in tandem with the P0916JW. In a manufacturing plant, the P0916JW can handle analog sensor data, while the FBM203 manages digital signals from switches and relays, creating a comprehensive I/O solution for the control system.

- FOXBORO CP40B Control Processor: The CP40B control processor pairs effectively with the P0916JW. In a power generation facility, the CP40B can receive processed data from the P0916JW and perform high – level control functions, ensuring stable power generation and distribution.

- FOXBORO P0971CD Communication Cable: This communication cable is specifically designed for use with FOXBORO I/O modules. When used with the P0916JW, it ensures reliable and high – speed data transmission between the module and other components of the control system, enhancing the overall stability of the industrial network.

- FOXBORO FBM242: The FBM242 is another analog I/O module that can complement the P0916JW. In a large – scale water treatment plant, the P0916JW can handle certain types of sensor inputs, while the FBM242 manages other analog signals like pH and conductivity measurements, providing a complete solution for water quality monitoring and control.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO P0916JW is designed to be straightforward. Its DIN – rail mountable design allows for quick and easy installation in standard industrial control cabinets. The wiring process is simple, with clearly marked terminals for input and output connections. The module also comes with detailed installation and configuration guides, enabling technicians, even those with limited experience, to install and set it up efficiently.

For maintenance, the P0916JW is equipped with self – diagnostic features. LED indicators on the module display the status of power, communication, and I/O channels, making it easy to identify any issues. In case of a component failure, FOXBORO offers a comprehensive range of high – quality replacement parts. The modular design of the P0916JW allows for quick and hassle – free replacement of faulty components, minimizing downtime.

FOXBORO provides extensive full – cycle support for the P0916JW. Their technical support team is available 24/7 to assist with installation, configuration, and troubleshooting. Regular software updates are provided to enhance the module’s performance, security, and compatibility with new industrial technologies. With FOXBORO’s support, customers can have peace of mind knowing that their P0916JW will operate reliably in their industrial applications for years to come.

Contact us for a customized solution tailored to your industrial automation requirements.