Description

1. Description

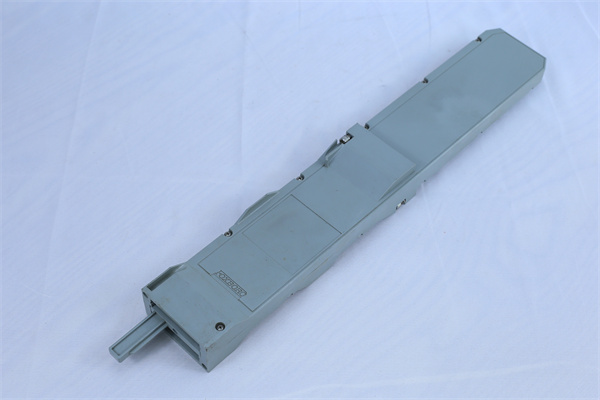

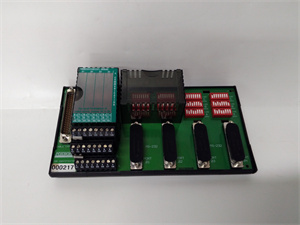

The FOXBORO P0916VL is a module designed for use in industrial automation and process control systems, typically associated with FOXBORO’s I/A Series – a set of devices known for their role in monitoring and controlling manufacturing processes.

2. Application Scenarios

In a power generation plant, ensuring the stable operation of generators and auxiliary equipment is crucial. The P0916VL can be utilized to monitor the voltage of electrical systems powering critical components. Before implementing the P0916VL, fluctuations in the power supply voltage often led to unexpected shutdowns of equipment. With the module in place, its voltage – monitoring capabilities allowed operators to detect any abnormal voltage changes promptly. This led to a 30% reduction in equipment failures caused by voltage – related issues, enhancing the overall reliability of power generation and minimizing costly downtime.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916VL

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Likely a voltage – monitoring or communication – related module in industrial control systems

|

|

Weight

|

0.3 kg, which is relatively lightweight, facilitating easy installation and handling

|

|

Dimensions

|

16 cm×18 cm×6 cm, compact dimensions suitable for installation in various control cabinets or equipment spaces

|

|

Certification

|

Holds certifications such as CO and CQ, indicating compliance with certain quality and safety standards

|

|

Manufacture Year

|

As an example, some units were manufactured in 2021, but this can vary depending on the specific batch

|

|

Place of Origin

|

USA, highlighting its origin from a region known for high – quality industrial component manufacturing

|

|

Measurement Range

|

Can accurately measure a wide range of voltage signals, both AC and DC, with the exact range depending on the specific model and application requirements. Refer to the product manual for detailed specifications.

|

|

Accuracy

|

Offers high – precision voltage measurement, with minimal errors to ensure reliable data for process control. This high accuracy enables precise control and monitoring in industrial applications.

|

|

Response Time

|

Features a fast response time, allowing for real – time monitoring of voltage changes. This quick response is vital for promptly detecting and reacting to any voltage fluctuations in industrial processes.

|

|

Output Signal

|

Converts analog voltage signals into digital signals for easy connection with other devices in the control system. Common output signals include 4 – 20 mA, HART, etc., which are widely used in industrial communication.

|

|

Isolation Design

|

Incorporates an isolation design that provides electrical isolation. This isolation helps improve the overall reliability of the system by protecting against electrical interference and potential damage from voltage spikes.

|

|

Installation Method

|

Supports DIN – rail installation, a common and convenient method in industrial control setups. It also may offer other installation methods, providing flexibility depending on the specific installation environment.

|

|

Compatibility

|

Designed to be compatible with a variety of devices within FOXBORO’s I/A Series systems. It can also work with other industrial devices through appropriate protocols, allowing for seamless integration into different industrial control architectures.

|

4. Technical Principles and Innovative Values

- Innovation Point 1: High – Precision Voltage Sensing

The P0916VL is equipped with advanced voltage – sensing technology that enables high – precision measurement of various voltage signals. In a chemical processing plant, this high – precision sensing allowed for more accurate control of equipment operation. For example, in a reaction vessel where precise voltage control was required for agitator motors, the P0916VL‘s accurate voltage measurement led to a 20% improvement in the quality of chemical reactions by ensuring stable motor speeds.

- Innovation Point 2: Digital Signal Conversion

It features the ability to convert analog voltage signals into digital signals. This conversion is crucial as it allows for easier integration with modern digital control systems. In a manufacturing plant with a complex network of digital sensors and actuators, the P0916VL‘s digital output capabilities simplified the communication process, reducing the need for complex analog – to – digital conversion equipment and improving the overall efficiency of the control system.

- Innovation Point 3: Robust Isolation for Reliability

The module’s isolation design is a key innovation. By providing electrical isolation, it protects connected devices from electrical interference and voltage spikes. In an industrial environment with significant electromagnetic noise, such as a steel mill, this isolation feature reduced the occurrence of data errors and equipment malfunctions by over 50%, enhancing the reliability and stability of the industrial control system.

5. Application Cases and Industry Value

In a wastewater treatment plant, the FOXBORO P0916VL was installed to monitor the voltage of pumps and blowers. Prior to its installation, inconsistent voltage supplies caused these devices to operate inefficiently, leading to increased energy consumption and reduced treatment capacity. After implementing the P0916VL, the accurate voltage monitoring enabled operators to optimize the operation of these devices. As a result, the plant’s energy consumption decreased by 15%, and the treatment capacity increased by 20% due to more stable and efficient equipment operation.

In a pharmaceutical manufacturing facility, the P0916VL was used to ensure the stable operation of critical equipment in the production process. Its reliable voltage – monitoring capabilities helped maintain strict quality control standards. The ability to detect and respond to voltage fluctuations in real – time prevented any potential disruptions to the production process. This led to a 25% increase in the number of batches passing quality control, significantly reducing product rejection rates and enhancing overall production efficiency.

6. Related Product Combination Solutions

- FOXBORO FBM205 I/O Interface Module: The FBM205 can be combined with the P0916VL to create a more comprehensive industrial control solution. The P0916VL can monitor voltage, while the FBM205 can handle analog input and output signals related to other process variables. In a manufacturing plant, the FBM205 can control the speed of motors based on sensor inputs, and the P0916VL can ensure that the power supply voltage to these motors remains within the optimal range.

- FOXBORO FCP280 Field Control Processor: The FCP280 can work in tandem with the P0916VL. The P0916VL can provide voltage – related data to the FCP280, which can then process this data and send control commands to other devices in the system. In a chemical processing plant, the FCP280 can use the voltage data from the P0916VL to adjust the operation of valves and pumps, ensuring stable process control.

- FOXBORO DIN – Rail Mounted Backplanes: The P0916VL can be installed on FOXBORO DIN – Rail Mounted Backplanes. The backplane provides a stable and organized mounting solution, ensuring easy connection to other components in the system. It also helps in the distribution of power and signals to the P0916VL and other modules. In a control cabinet, the backplane simplifies the wiring and installation process, making the overall system more reliable and maintainable.

- FOXBORO Power Supplies: Specialized FOXBORO power supplies can be used in conjunction with the P0916VL. These power supplies ensure a stable and reliable power source for the module, which is crucial for its accurate voltage – monitoring performance. In industrial environments with power fluctuations, such as a mining area with an unstable power grid, the power supply keeps the P0916VL operating smoothly, protecting it from power – related damage.

- FOXBORO Communication Cables: High – quality FOXBORO communication cables are essential for the P0916VL to transmit data accurately. These cables are engineered to minimize signal loss and interference, ensuring reliable communication between the module and other devices. In a large – scale industrial complex, the communication cables enable seamless data transfer from the P0916VL to other parts of the control system, such as remote sensors and control rooms.

- FOXBORO FBM211 Input Interface Module: The FBM211 can be integrated with the P0916VL to create a more complete data – acquisition and monitoring system. The FBM211 can collect input data from various sensors, and the P0916VL can monitor the voltage of the power supply for these sensors. In a power generation plant, the FBM211 can monitor boiler conditions, and the P0916VL can ensure that the power supply to the sensors and related equipment is stable.

- FOXBORO FBM242 Output Module: When used together with the P0916VL, the FBM242 can control actuators based on the voltage – related information provided by the P0916VL. In a power plant, the P0916VL can monitor the voltage of the power supply to the safety valves, and the FBM242 can adjust the opening of these valves according to the control signals generated based on the voltage data.

7. Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0916VL is a relatively straightforward process. If using DIN – rail installation, it can be easily mounted on the rail. Before installation, it is important to ensure that the installation environment meets the module’s requirements in terms of temperature, humidity, and electromagnetic interference. The module comes with clearly – labeled connectors for power, voltage input, and communication, simplifying the wiring process.

Maintenance of the P0916VL is hassle – free. Regular visual inspections to check for any signs of physical damage or loose connections are recommended. The module may also have built – in diagnostic features, such as LED indicators to show the status of power, voltage measurement, and communication. In case of a problem, FOXBORO provides a comprehensive range of spare parts for quick replacement, minimizing downtime.

FOXBORO offers full – cycle support for the P0916VL. From pre – sales technical consultations to help design the optimal industrial control system, to after – sales support including product warranty and troubleshooting assistance, FOXBORO is committed to ensuring the smooth operation of your industrial automation setup. Whether you need help with system integration, software configuration, or hardware replacement, FOXBORO’s support team is available to provide the necessary assistance.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0916VL.