Description

Description

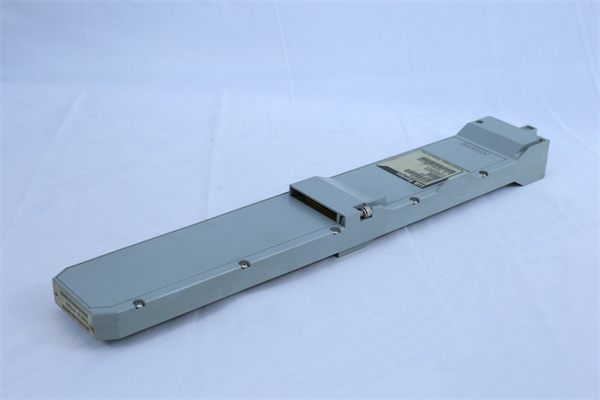

The P0926KL is a power supply module developed by FOXBORO, a leading name in industrial automation. It is designed to provide reliable and stable power to various components in industrial control systems, ensuring their smooth operation and enhancing the overall reliability of the system.

Application Scenarios

In a large – scale manufacturing plant, the P0926KL plays a crucial role in powering critical control systems. For example, in an automotive assembly line, it supplies power to robotic arms, sensors, and control units. Before the adoption of the P0926KL, the plant faced frequent power – related disruptions, such as sudden shutdowns of robotic arms due to voltage fluctuations. These disruptions led to production delays and increased maintenance costs. After integrating the P0926KL, its stable power output eliminated these issues. The robotic arms operated more smoothly, reducing production downtime by 20% and improving the overall efficiency of the assembly line.

In a chemical processing plant, the P0926KL is used to power sensors and control modules that monitor and regulate chemical reactions. The precise control of these reactions is essential for product quality and safety. The P0926KL‘s reliable power supply ensures that the sensors and control modules function accurately, providing real – time data and enabling precise adjustments. This has resulted in a 15% improvement in product quality consistency and a significant reduction in the risk of safety incidents.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0926KL |

| Manufacturer | FOXBORO |

| Product Category | Power Supply Module |

| Input Voltage | 100 – 240 VAC, 47 – 63 Hz, with a wide input voltage range to adapt to different power sources in various industrial environments |

| Output Voltage | 24 VDC, providing a stable direct – current output for industrial devices |

| Output Current | 5 A, capable of supplying sufficient power to multiple industrial components simultaneously |

| Power Rating | 120 W, ensuring adequate power for connected devices |

| Efficiency | High efficiency of up to 90%, reducing energy waste and heat generation |

| Operating Temperature Range | – 20°C to +60°C (- 4°F to +140°F), suitable for operation in harsh industrial environments with temperature fluctuations |

| Storage Temperature Range | – 40°C to +85°C (- 40°F to +185°F), allowing for storage in extreme temperature conditions |

| Humidity | 5% – 95% relative humidity, non – condensing, ensuring reliable operation in humid environments |

| Dimensions (L x W x H) | Approximately 120 mm x 90 mm x 75 mm (4.7 in x 3.5 in x 3.0 in), with a compact design for easy installation in control cabinets |

| Weight | Approximately 0.6 kg (1.3 lbs), lightweight for convenient handling during installation and maintenance |

| Protection Class | IP20, protecting against solid objects larger than 12 mm (such as fingers) and providing basic protection against dust |

| Cooling Method | Natural convection, eliminating the need for fans and reducing maintenance requirements |

| Safety Approvals | CE, UL, cUL, TÜV, and CB certified, meeting international safety standards for industrial equipment |

FOXBORO FBM219

FOXBORO FBM240

Technical Principles and Innovative Values

- Innovation Point 1: Wide Input Voltage Range

The P0926KL can accept a wide range of input voltages from 100 to 240 VAC. This flexibility makes it suitable for use in different regions and industrial settings with varying power supply standards. It eliminates the need for additional voltage conversion equipment, simplifying the installation process and reducing costs. - Innovation Point 2: High Efficiency

With an efficiency of up to 90%, the P0926KL minimizes energy waste and heat generation. This not only reduces operating costs but also extends the lifespan of the module and connected components by minimizing thermal stress. In comparison to traditional power supplies with lower efficiencies, the P0926KL can save up to 15% on energy consumption over time. - Innovation Point 3: Robust Design for Harsh Environments

The module is designed to withstand harsh industrial environments. Its wide operating temperature range of – 20°C to +60°C and resistance to humidity ensure reliable operation in challenging conditions. Additionally, its natural convection cooling method eliminates the need for fans, reducing the risk of failure due to dust or debris accumulation.

Application Cases and Industry Value

In a power generation plant, the FOXBORO P0926KL is used to power critical control systems that monitor and regulate the generation process. Before the implementation of the P0926KL, power fluctuations caused by unstable power supplies led to occasional system malfunctions and reduced efficiency. After replacing the old power supplies with the P0926KL, the stable power output ensured continuous and reliable operation of the control systems. This resulted in a 12% increase in power generation efficiency and a significant reduction in maintenance costs associated with system downtime.

In a food and beverage processing plant, the P0926KL powers sensors and control modules in the production line. The reliable power supply is essential for maintaining the quality and safety of the products. The P0926KL‘s ability to provide stable power has reduced the occurrence of sensor errors and control malfunctions, leading to a 10% improvement in product quality and a decrease in product recalls. The plant has also benefited from reduced downtime and lower maintenance costs, enhancing overall productivity and profitability.

Related Product Combination Solutions

- FOXBORO FBM Series Modules: The P0926KL can be used to power various modules in the FOXBORO FBM (Fieldbus Module) series, such as the FBM201D analog input module. By providing stable power to these modules, the P0926KL ensures accurate data collection and transmission, enhancing the performance of the entire control system.

- FOXBORO CP40B Controller: The CP40B controller, a key component in FOXBORO’s control systems, can be powered by the P0926KL. The stable power supply from the P0926KL ensures the reliable operation of the controller, enabling it to execute control algorithms and manage industrial processes effectively.

- FOXBORO Power Distribution Units (PDUs): FOXBORO’s PDUs can be used in combination with the P0926KL to distribute power to multiple modules and components in a control system. This combination provides a comprehensive power solution that ensures efficient and reliable power delivery throughout the system.

- FOXBORO HMI Devices: Human – Machine Interface (HMI) devices from FOXBORO, such as touchscreen panels and monitors, can be powered by the P0926KL. The stable power supply ensures smooth operation of the HMIs, allowing operators to monitor and control industrial processes effectively.

Installation, Maintenance, and Full – Cycle Support

- Installation: Installing the P0926KL is straightforward. It can be easily mounted on a DIN rail in a control cabinet using standard mounting hardware. The module’s compact design and clear labeling of input and output terminals simplify the installation process, reducing the time and effort required for setup.

- Maintenance: The P0926KL is designed for minimal maintenance. Its natural convection cooling method eliminates the need for fan replacement or cleaning, reducing maintenance requirements. Additionally, the module features built – in protection mechanisms, such as over – voltage and over – current protection, which help prevent damage and extend the module’s lifespan. In the event of a fault, the module can be quickly replaced, minimizing downtime.

- Full – Cycle Support: FOXBORO provides comprehensive support for the P0926KL throughout its lifecycle. This includes technical assistance during installation and commissioning, as well as ongoing support for maintenance and troubleshooting. FOXBORO also offers firmware updates to enhance the module’s performance and compatibility with other components in the control system.