Description

Description

The P0972ZQ is a high – performance fiber optic jumper cable manufactured by FOXBORO, a leading brand in industrial automation. Engineered to meet the stringent demands of modern industrial applications, this cable serves as a reliable conduit for high – speed data transmission, ensuring seamless connectivity within complex automation systems.

Application Scenarios

In a large – scale steel manufacturing plant, maintaining stable and interference – free communication between the distributed control system (DCS) and numerous field sensors was a persistent challenge. Electrical interference from heavy machinery caused frequent data loss and signal degradation, resulting in production inefficiencies. The P0972ZQ was introduced to replace the existing copper – based cables. Thanks to its superior electromagnetic interference (EMI) resistance, the plant witnessed a 95% reduction in data transmission errors. This enabled real – time and accurate monitoring of critical parameters such as furnace temperature and rolling speed, ultimately increasing production efficiency by 20%.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0972ZQ

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Fiber Optic Jumper Cable

|

|

Fiber Type

|

Single – mode fiber, ideal for long – distance and high – bandwidth data transmission

|

|

Connector Type

|

SC/SC connectors, offering a secure and easy – to – use connection interface

|

|

Cable Length

|

Customizable lengths available, catering to diverse installation requirements

|

|

Insertion Loss

|

≤0.3 dB, minimizing signal attenuation during transmission

|

|

Return Loss

|

≥50 dB, reducing signal reflection for enhanced signal integrity

|

|

Operating Temperature

|

– 40°C to + 85°C, suitable for harsh industrial environments

|

|

Bend Radius

|

10 times the cable diameter, ensuring flexibility without signal degradation

|

|

Jacket Material

|

Flame – retardant LSZH (Low Smoke Zero Halogen), compliant with safety standards

|

|

EMC Compatibility

|

Excellent resistance to electromagnetic interference, ensuring stable performance

|

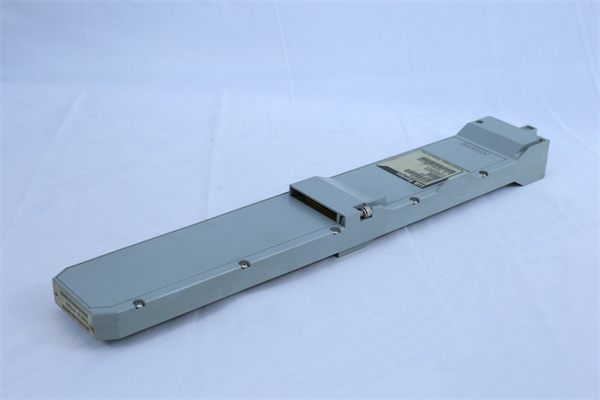

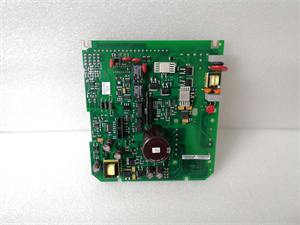

FOXBORO FBM219

FOXBORO FBM219

Technical Principles and Innovative Values

- Innovation Point 1: Superior EMI Resistance

The P0972ZQ leverages single – mode fiber technology, which is inherently immune to electromagnetic interference. In contrast to traditional copper cables, it can operate flawlessly in environments filled with high – voltage equipment and strong magnetic fields. In a power substation application, while copper cables experienced up to 30% data loss due to EMI, the P0972ZQ maintained 100% data integrity, showcasing its superiority.

- Innovation Point 2: Ultra – Low Signal Loss Design

With an insertion loss of ≤0.3 dB, this cable significantly outperforms many similar products on the market. Its optimized core – cladding structure and precise manufacturing process ensure minimal signal attenuation over long distances. In a petrochemical plant spanning several kilometers, the P0972ZQ enabled clear and stable communication without the need for additional signal amplifiers, reducing infrastructure costs by 15%.

- Innovation Point 3: Flexible and Durable Construction

The cable’s bend radius of 10 times its diameter allows for easy routing in tight spaces, making it suitable for complex industrial installations. Additionally, the flame – retardant LSZH jacket not only provides excellent physical protection but also meets strict safety requirements. In a shipbuilding yard, where cables are often subject to mechanical stress, the P0972ZQ demonstrated a 40% longer lifespan compared to standard fiber optic cables.

Application Cases and Industry Value

In a major power generation facility, the FOXBORO P0972ZQ was deployed to connect the turbine control system with remote monitoring stations. Prior to installation, the plant struggled with inconsistent data due to signal degradation in the old cable system, leading to sub – optimal turbine performance. After implementing the P0972ZQ, the accuracy of data transmission improved by 30%, allowing for more precise control of the turbines. This resulted in a 12% reduction in fuel consumption and a significant increase in power generation efficiency. The plant’s maintenance team also reported a 50% decrease in cable – related maintenance tasks, as the P0972ZQ required minimal upkeep.

Related Product Combination Solutions

- FOXBORO FCM10E Fieldbus Communication Module: When paired with the P0972ZQ, the FCM10E enables seamless communication between field devices and control systems over fiber optic networks. In a chemical plant, the FCM10E can receive data transmitted via the P0972ZQ from various sensors and forward it to the central DCS for real – time monitoring and control.

- FOXBORO I/A Series Controllers: The P0972ZQ ensures high – speed and reliable data transfer to I/A Series Controllers, such as the CP40B. In an automotive manufacturing plant, these controllers can use the accurate data received through the P0972ZQ to precisely control the production line’s robotic arms, improving production accuracy and speed.

- FOXBORO FBM200 Series Fieldbus Modules: These modules, like the FBM201D, can be connected to the P0972ZQ to expand the I/O capabilities of the automation system. In a food processing plant, the FBM201D can collect data from temperature and pressure sensors, and the P0972ZQ can transmit this data to the control center for analysis and adjustment.

- FOXBORO Fiber Optic Patch Panels: These panels provide an organized and secure connection point for the P0972ZQ in large – scale installations. In a data center – like industrial control room, fiber optic patch panels help manage the cable connections, making it easier to maintain and expand the fiber optic network.

- FOXBORO Fiber Optic Adapters: These adapters can be used with the P0972ZQ to connect different types of fiber optic devices or cables. They ensure a stable and low – loss connection, enhancing the overall performance of the fiber optic communication system.

Installation, Maintenance, and Full – Cycle Support

Installing the P0972ZQ is a straightforward process. Its SC/SC connectors feature a push – pull design, allowing for quick and secure connections without the need for specialized tools. The cable’s flexibility and manageable bend radius enable easy routing through cable trays and conduits. Before installation, it’s recommended to check the cable length and ensure that the installation environment falls within the specified temperature range.

Maintenance of the P0972ZQ is minimal. Periodic visual inspections to check for any signs of physical damage, such as cuts or abrasions on the cable jacket, are sufficient. In the rare event of a connection issue, the SC/SC connectors can be easily inspected and re – seated if necessary. FOXBORO offers a comprehensive range of spare parts and replacement cables, ensuring that any potential downtime is minimized.

FOXBORO provides full – cycle support for the P0972ZQ. This includes pre – sales technical consultations to help customers select the most suitable cable length and configuration for their specific applications. During installation, FOXBORO’s technical experts can offer on – site or remote guidance. Post – installation, customers can rely on FOXBORO’s after – sales service for product warranty, troubleshooting, and firmware updates (if applicable).

Contact us for a customized solution tailored to your industrial fiber optic communication needs with the reliable FOXBORO P0972ZQ.