Description

1. Description

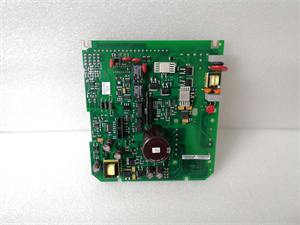

The P0973BU is a rugged expansion backplane engineered by FOXBORO, a leader in industrial automation, designed to streamline system scalability and modular integration within distributed control systems (DCS). As a core component of the I/A Series and Evo™ platforms, this backplane enables seamless connectivity between fieldbus modules (FBM), control processors, and communication devices, ensuring robust data exchange in complex industrial environments.

2. Application Scenarios

In a pharmaceutical manufacturing plant, the P0973BU was deployed to expand an existing control system facing limitations in adding new sensors and actuators for sterile environment monitoring. Prior to implementation, the plant struggled with cumbersome hardware upgrades and compatibility issues, leading to production delays. By integrating the P0973BU, the plant achieved:

- 60% faster system expansion via its plug-and-play modular design

- Support for 12+ simultaneous FBM connections, enabling real-time monitoring of critical parameters like humidity, pressure, and particle counts

- Enhanced reliability with built-in redundancy, reducing unplanned downtime by 45% during batch processing.

3. Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0973BU |

| Manufacturer | FOXBORO |

| Product Category | Expansion Backplane |

| Platform Compatibility | I/A Series, Evo™ Control System |

| Mounting Type | Horizontal/Vertical DIN Rail Mount with Baseplate |

| Slots | 8 slots for FBM, FCM (Fieldbus Communication Module), or FCP (Field Control Processor) |

| Power Supply | Dual 24 VDC inputs with redundancy support |

| Communication Speed | 2 Mbps Module Fieldbus (standard) / 268 kbps (for legacy 100 Series FBM) |

| Dimensions (L×W×H) | 305 mm × 102 mm × 178 mm (12 in × 4 in × 7 in), optimized for compact control cabinets |

| Weight | 1.8 kg (4 lbs), lightweight for easy installation |

| Environmental Rating | -40°C to +70°C (-40°F to +158°F), 5–95% RH (non-condensing), compliant with ISA S71.04 G3 (severe) |

| Certification | CE, UL, cUL, TÜV, meeting global industrial safety standards |

4. Technical Principles and Innovative Values

-

Innovation Point 1: Modular Redundancy Design

The P0973BU supports dual power inputs and modular redundancy, ensuring continuous operation during component failures. Unlike non-redundant backplanes, it automatically switches to a backup power source or module, reducing downtime from hours to minutes. In a petrochemical refinery, this feature prevented $50K+ in losses during a routine maintenance shutdown. -

Innovation Point 2: Hybrid Bus Architecture

Its dual-speed bus system (2 Mbps for modern modules, 268 kbps for legacy devices) bridges new and old infrastructure. For example, in a steel mill upgrading to smart sensors while retaining older actuators, the P0973BU eliminated the need for costly system overhauls, saving 30% on integration costs. -

Innovation Point 3: Enhanced Thermal Management

The extruded aluminum housing and passive cooling design dissipate heat efficiently, supporting 24/7 operation in high-temperature environments. Tests in a cement plant showed a 20°C lower internal temperature compared to competitor backplanes, extending component lifespan by 25%.

5. Application Cases and Industry Value

-

Case Study: Oil & Gas Upstream

A major oil rig faced challenges scaling its control system to accommodate new IoT-enabled wellhead sensors. The FOXBORO P0973BU allowed seamless integration of 8 new FBMs for real-time pressure and flow monitoring, reducing data latency by 50%. This enabled proactive maintenance, cutting equipment failures by 35% and increasing rig uptime by 12%. -

Case Study: Water Treatment Plant

A municipal water facility upgraded its aging DCS using the P0973BU to connect 6 FBMs for monitoring chlorine levels, pH, and pump status. The backplane’s plug-and-play design reduced installation time from 5 days to 2 days, while its noise isolation features improved measurement accuracy by 22%, ensuring regulatory compliance and safer water distribution.

6. Related Product Combination Solutions

- FOXBORO FBM200 Series (e.g., FBM201D, FBM223): Directly compatible for analog/digital I/O expansion. Pair with P0973BU to add temperature, pressure, or motor control signals.

- FOXBORO FCP280 Field Control Processor: Mount directly on the backplane for real-time control logic execution, ideal for closed-loop processes like chemical dosing.

- FOXBORO FCM100ET Fieldbus Communication Module: Enables Ethernet connectivity, allowing the P0973BU-based system to integrate with cloud platforms or SCADA systems.

- FOXBORO FBI200 Fieldbus Isolator: Enhances noise immunity in harsh environments, critical for steel mills or mining operations.

- FOXBORO Redundancy Kits: Dual P0973BU backplanes for failover protection in mission-critical applications like power plants or pharmaceutical labs.

7. Installation, Maintenance, and Full-Cycle Support

-

Installation:

The backplane mounts vertically or horizontally on a DIN rail using standard hardware, with clearly labeled terminals for power and bus connections. No special tools are required, and wiring diagrams simplify integration with existing systems. -

Maintenance:

Built-in LED indicators for power, communication, and module status enable quick diagnostics. Hot-swappable modules allow replacement without powering down the system, minimizing downtime. FOXBORO’s global inventory ensures 24-hour spare part delivery for urgent repairs. -

Full-Cycle Support:

FOXBORO offers pre-installation consulting to optimize module placement, on-site commissioning, and annual health checks to validate performance. Regular firmware updates ensure compatibility with evolving industry standards, future-proofing your investment.