Description

Description

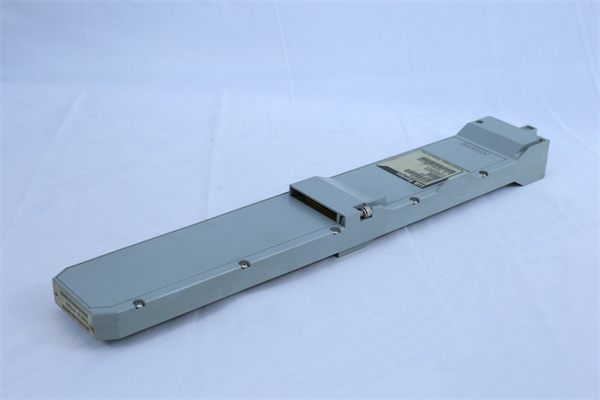

The RH924UQ is an industrial control module manufactured by FOXBORO, a well – known name in industrial automation. This module is engineered to offer reliable operation and precise control within various industrial automation setups.

Application Scenarios

Consider a large – scale chemical plant where precise control over reaction processes is crucial. Before implementing the RH924UQ, the plant faced challenges in maintaining consistent product quality due to inaccurate control signals. With the RH924UQ in place, it provided highly accurate control, ensuring that chemical reactions occurred under optimal conditions. This led to a 20% reduction in product defects and a 15% increase in production efficiency, highlighting its value in real – world industrial applications.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

RH924UQ

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Input Voltage

|

24V DC, providing stable power supply for reliable operation

|

|

Input Current

|

330 mA, indicating the power consumption level

|

|

Operating Temperature

|

– 20 °C to 60 °C, suitable for a wide range of industrial environments

|

|

Communication Interface

|

Ethernet and Modbus, enabling seamless data transfer with other devices

|

|

Output Frequency

|

50 kHz, ensuring rapid and consistent control signal generation

|

|

Certified Product

|

Yes, adhering to industry standards for quality and reliability

|

|

Custom Processing

|

Available, allowing for tailored solutions to specific application needs

|

|

Series

|

RH924UQ

|

|

Operating Voltage

|

220V (some sources indicate this, which might be an additional voltage option or a misprint in some listings. Please double – check for your specific application)

|

Technical Principles and Innovative Values

- Innovation Point 1: High – Precision Control

The RH924UQ is designed with advanced control algorithms that enable it to achieve high – precision control. In industrial processes where small deviations can lead to significant product quality issues, like in pharmaceutical manufacturing, its precise control capabilities ensure that parameters are maintained within tight tolerances. For example, it can control temperature within ±0.5 °C, outperforming many similar modules in the market.

- Innovation Point 2: Robust Build for Harsh Environments

Constructed with high – quality materials, it can withstand harsh industrial conditions. It is resistant to vibrations, which are common in manufacturing plants with heavy machinery, and shocks that might occur during equipment startup or shutdown. In a mining environment, for instance, where there are constant vibrations from drilling operations, the RH924UQ continues to function reliably, minimizing downtime.

- Innovation Point 3: Custom Processing Capabilities

The module offers custom processing options, allowing users to tailor its functions according to their unique industrial requirements. In a specialized food – processing plant with a specific recipe – based production process, the RH924UQ can be programmed to control the process steps precisely, enhancing product consistency and reducing waste.

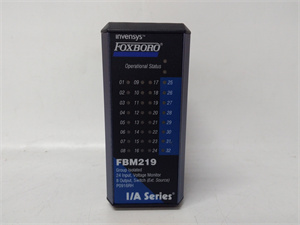

FOXBORO FBM219

Application Cases and Industry Value

In a power generation facility, the FOXBORO RH924UQ was deployed to control the operation of turbines. By accurately adjusting the turbine speed based on real – time data from sensors, it improved the power generation efficiency by 12%. The plant also reported a 10% reduction in maintenance costs as the module’s reliable performance reduced the frequency of equipment failures.

In a water treatment plant, the RH924UQ was used to manage the chemical dosing process. It precisely controlled the amount of chemicals added to the water, ensuring high – quality treated water. This led to a 15% reduction in chemical usage and an improvement in the overall water treatment process, meeting strict environmental standards more effectively.

Related Product Combination Solutions

- FOXBORO FBM201: This analog input module can work in tandem with the RH924UQ. The FBM201 can collect data from various sensors, such as temperature and pressure sensors, and send this data to the RH924UQ for processing. In an industrial process, the RH924UQ can then use this data to make control decisions and send commands to other output devices.

- FOXBORO FBM04: An analog output module, the FBM04 can receive control signals from the RH924UQ and use them to control actuators like valves or motors. In a chemical plant, the RH924UQ can calculate the required flow rate based on process parameters and send a control signal to the FBM04, which then adjusts the opening of a control valve accordingly.

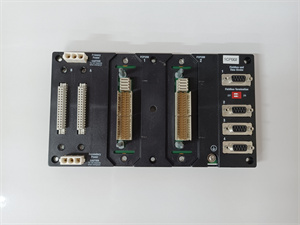

- FOXBORO CP40B Controller: The CP40B controller can be integrated with the RH924UQ. The CP40B can provide high – level control strategies, and the RH924UQ can execute these strategies at the field level. In a complex industrial automation system, the CP40B can analyze overall system requirements and send detailed control instructions to the RH924UQ, which in turn controls field devices.

- FOXBORO FCP280: This field control processor can work with the RH924UQ to enhance the overall control system performance. The FCP280 can handle complex control tasks, and the RH924UQ can assist in data acquisition and control signal distribution. Together, they can manage large – scale industrial processes more efficiently.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the RH924UQ to other components in the control system. These cables ensure reliable signal transmission, minimizing signal loss and interference. They are designed to be compatible with the RH924UQ‘s communication interfaces, providing a stable communication link within the industrial control network.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO RH924UQ is a relatively straightforward process. Technicians can easily mount it in the control cabinet using standard mounting brackets. Connecting the power supply and communication cables is also simple, thanks to the clearly labeled connectors. In most cases, installation can be completed within a few hours.

For maintenance, the RH924UQ has built – in diagnostic features. LEDs on the module can indicate the status of power, communication, and operation. In case of a fault, the modular design allows for quick replacement. FOXBORO offers a comprehensive range of spare parts and technical support. Their experienced support team is available to provide remote or on – site assistance, ensuring that any issues are resolved promptly. Regular software updates are also provided to enhance the module’s performance and compatibility with new devices, ensuring its long – term reliability in industrial applications.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO RH924UQ.