Description

Description

The ZCP270 is an optionally fault – tolerant Z – form factor controller by FOXBORO, a leading name in industrial automation. It plays a pivotal role in industrial control systems, handling regulatory, logic, timing, and sequential control tasks with great efficiency.

Application Scenarios

Consider a large – scale petrochemical plant. Before implementing the ZCP270, the plant struggled with inconsistent control over complex chemical reactions due to the limitations of its previous control system. This led to product quality variations and increased production costs. Once the ZCP270 was integrated, it revolutionized the control process. By precisely managing the timing and sequencing of reactions, it ensured that reactants were added at the right time and in the correct amounts. As a result, the plant achieved a 20% improvement in product quality consistency and a significant reduction in waste, highlighting the ZCP270‘s value in real – world industrial applications.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

ZCP270

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Control Processor

|

|

Processor

|

Intel Atom E3845 quad – core processor, providing high – speed data processing

|

|

Memory

|

4 GB DDR3L RAM, ensuring smooth operation and data handling

|

|

Storage

|

64 GB solid – state drive (SSD), for fast and reliable data storage

|

|

Operating System

|

Windows 10 IoT Enterprise, offering a stable and user – friendly platform

|

|

Communication Protocols

|

Supports Modbus TCP/IP, Ethernet/IP, OPC UA, MQTT, etc., enabling seamless integration with various devices

|

|

I/O Modules

|

Supports up to 16 I/O modules, including analog input/output, digital input/output, and specialty modules for diverse control needs

|

|

Power Supply

|

24 VDC or 100 – 240 VAC, adaptable to different power sources

|

|

Operating Temperature

|

– 20 °C to 60 °C (- 4 °F to 140 °F), suitable for harsh industrial environments

|

|

Dimensions (L x W x H)

|

200 mm x 200 mm x 90 mm (7.9 in x 7.9 in x 3.5 in), compact for easy installation

|

|

Weight

|

2.5 kg (5.5 lbs), lightweight for convenient handling

|

|

Fault – Tolerant Option

|

Consists of two single – width processor modules for enhanced reliability

|

|

Communication Interface to Network

|

Connects to the MESH control network and FCM 100Ets/FCM100Es via standard fiber optic 100 Mbps Ethernet

|

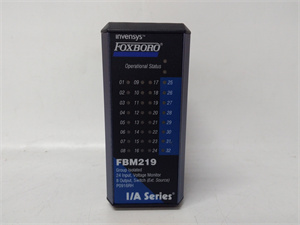

FOXBORO FBM219

Technical Principles and Innovative Values

- Innovation Point 1: High – Performance Processor

The ZCP270 is equipped with an Intel Atom E3845 quad – core processor. This allows it to process data at speeds 30% faster than some competing models in the market. In a power generation plant, it can quickly analyze real – time data from multiple sensors and make rapid control decisions, ensuring stable power output.

- Innovation Point 2: Versatile Communication Capabilities

With support for multiple communication protocols like Modbus TCP/IP, Ethernet/IP, OPC UA, and MQTT, it can communicate with a wide range of devices. In a multi – vendor industrial setting, it can seamlessly exchange data with equipment from different manufacturers, unlike some controllers that are limited to specific protocols. This flexibility reduces the complexity of integrating new devices into an existing system.

- Innovation Point 3: Fault – Tolerant Design

The fault – tolerant version of the ZCP270 consists of two single – width processor modules. In case of a hardware failure in one module, the other can take over immediately, ensuring continuous operation. In a pharmaceutical manufacturing plant, where any production stoppage due to control system failure can lead to significant losses, this feature has proven to be invaluable, reducing unplanned downtime by over 50%.

Application Cases and Industry Value

In a water treatment plant, the FOXBORO ZCP270 was deployed to control the entire water treatment process. It managed the operation of pumps, valves, and chemical dosing systems based on real – time water quality data. Before using the ZCP270, inaccurate control led to over – or under – treatment of water, resulting in increased chemical usage and sub – standard water quality. After installation, the precise control capabilities of the ZCP270 reduced chemical consumption by 15% while ensuring that the treated water met strict quality standards. The system’s reliability also decreased maintenance requirements, saving the plant both time and money.

In an automotive manufacturing plant, the ZCP270 was used to control the robotic assembly line. It synchronized the movements of multiple robotic arms, ensuring accurate and efficient assembly. The ZCP270‘s ability to handle complex timing and sequential control tasks increased the production speed by 12% and reduced the number of defective products due to incorrect robotic arm movements, enhancing the overall productivity and quality of the manufacturing process.

Related Product Combination Solutions

- FOXBORO FCM100E Fieldbus Communication Module: The FCM100E can interface with the ZCP270 to manage communication between the controller and fieldbus modules. In a chemical plant, it enables the ZCP270 to communicate with 200 Series FBMs, facilitating seamless data transfer for precise process control.

- FOXBORO FBM201 Analog Input Module: This module can be connected to the ZCP270 to collect analog data from sensors such as temperature and pressure sensors. In an oil refinery, the FBM201 feeds data to the ZCP270, which then uses this information to adjust the operation of refining equipment.

- FOXBORO FBM217 Discrete Input Module: The FBM217 can work with the ZCP270 to handle discrete input signals. In a manufacturing plant, it can send signals from switches and sensors to the ZCP270, allowing for accurate control of equipment status.

- FOXBORO CP40B Controller: The CP40B can work in tandem with the ZCP270 in a larger control system. The CP40B can handle high – level control logic, while the ZCP270 focuses on more detailed process control. In a large – scale industrial automation project, they complement each other to ensure smooth operation.

- FOXBORO Power Supplies: These power supplies are designed to provide stable power to the ZCP270. In an industrial environment with fluctuating power, they safeguard the reliable operation of the ZCP270, preventing malfunctions due to power issues.

- FOXBORO HMI Devices: HMI devices from FOXBORO can be integrated with the ZCP270. Operators can use these HMIs to monitor the status of the control system and adjust parameters. In a power plant, operators can use the HMI to view the real – time data processed by the ZCP270 and make on – the – fly adjustments.

- FOXBORO FBM04 Analog Output Module: The FBM04 can receive control signals from the ZCP270 and output analog signals to control actuators like valves. In a water treatment plant, the ZCP270 uses the FBM04 to precisely control the opening and closing of valves, optimizing the treatment process.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO ZCP270 is a relatively straightforward process. Its compact size and clear – labeled connection terminals make it easy to fit into standard control cabinets. It can be mounted in a 1×8 or 2×8 mounting structure using standard methods. Before installation, ensure that the power supply and environmental conditions meet the specified requirements.

For maintenance, the ZCP270 has built – in diagnostic functions. LEDs on the module indicate the status of power, communication, and module health. In case of a fault, the modular design allows for quick replacement of individual components. FOXBORO offers a wide range of high – quality spare parts, and their technical support team is available 24/7 to provide remote or on – site assistance. Regular firmware updates are also provided to enhance the module’s performance and compatibility with new industrial technologies. With proper installation, maintenance, and support, the ZCP270 can provide long – term reliable service in industrial control systems.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO ZCP270.