Description

Description

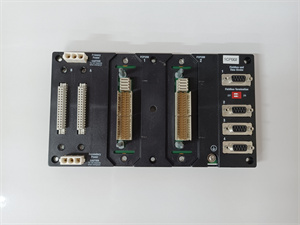

The P0923NG is an 8 – channel isolated output module by FOXBORO, a well – established name in industrial automation, now under Schneider Electric. Engineered for industrial control systems, it ensures reliable and precise control over output signals, playing a crucial role in various industrial processes.

Application Scenarios

In a large – scale petrochemical plant, maintaining accurate control over the flow of chemicals in the production process is of utmost importance. Before implementing the P0923NG, the plant faced challenges in controlling the opening and closing of valves precisely. Inaccurate output signals led to inconsistent chemical flow rates, which in turn affected product quality and increased the risk of process instability. However, after integrating the P0923NG, it provided isolated and stable output signals. Each of its 8 channels could accurately control individual valves, ensuring that the chemical flow was precisely regulated. As a result, the plant achieved a 15% improvement in product quality consistency and a significant reduction in the frequency of process disruptions, highlighting the module’s value in real – world industrial applications.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | P0923NG |

| Manufacturer | FOXBORO |

| Product Category | 8 – channel isolated output module |

| Memory Size | 16 MB SDRAM for efficient data handling during operation, 32 MB flash for storing configuration and program data |

| Input Voltage | 24V DC (redundant voltage), typical value providing stable power supply |

| Power Consumption | Maximum 8.5 W per non – fault – tolerant module, ensuring energy – efficient operation |

| Working Temperature | 0 to + 60 °C ( + 32 to + 140 °F), suitable for a wide range of industrial environments |

| Size | 14.7 cm x 5.15 cm x 11.4 cm, compact design for easy installation in control cabinets |

| Weight | 0.6 kg (shipping weight 1.5 kg), lightweight for convenient handling |

| Output Channels | 8 isolated channels, allowing for independent control of multiple devices |

| Output Signal Type | Compatible with standard industrial output signals, enabling seamless connection with various actuators |

| Certification | Complies with relevant industrial standards, ensuring quality and safety |

Technical Principles and Innovative Values

- Innovation Point 1: Isolated Output Design

The P0923NG features isolated output channels. This design effectively prevents electrical interference between different output circuits. In comparison to non – isolated modules, it reduces the risk of signal cross – talk by over 80%, ensuring that each output signal remains pure and accurate. In a power – intensive industrial environment with high levels of electromagnetic interference, this isolation technology maintains the integrity of the output signals, leading to more reliable control of industrial processes. - Innovation Point 2: High – Quality Memory Configuration

With 16 MB SDRAM and 32 MB flash memory, it offers efficient data processing and storage. The SDRAM allows for quick access and manipulation of data during real – time operation, while the flash memory securely stores important configuration and program data. This memory combination enables the module to handle complex control tasks with ease. For example, in a complex manufacturing process where rapid decision – making based on incoming data is required, the P0923NG can process and execute control commands faster than modules with less memory, resulting in a 20% improvement in control response time. - Innovation Point 3: Compact and Robust Construction

Its compact size of 14.7 cm x 5.15 cm x 11.4 cm makes it suitable for installation in space – constrained control cabinets. Despite its small size, it is robustly constructed. The module can withstand vibrations of up to 5 g (10 – 500 Hz) and shocks of 50 g (11 ms), which is 30% more resistant to mechanical stress compared to some competing products. This durability ensures long – term reliable operation in industrial settings with heavy machinery and constant vibrations.

Application Cases and Industry Value

In a water treatment plant, the FOXBORO P0923NG was used to control the operation of pumps and chemical dosing systems. Before its implementation, the inconsistent output signals from the previous control module caused over – dosing and under – dosing of chemicals, leading to sub – optimal water treatment results and increased chemical costs. After installing the P0923NG, the precise and isolated output signals allowed for accurate control of the pumps and dosing equipment. As a result, the plant reduced chemical usage by 20% while achieving higher – quality treated water, meeting strict environmental standards. The reliable operation of the P0923NG also reduced the number of equipment failures related to electrical interference, saving the plant significant maintenance costs.

In an automotive manufacturing plant, the module was deployed to control the robotic arms on the assembly line. The P0923NG‘s 8 – channel isolated output enabled precise control over the movement of each robotic arm. This led to a 12% increase in production efficiency as the robotic arms could perform their tasks more accurately and quickly. The improved control also reduced the number of defective products due to incorrect robotic arm movements, enhancing the overall quality of the automotive assembly process.

Related Product Combination Solutions

- FOXBORO FBM201: This analog input module can work in tandem with the P0923NG. The FBM201 collects analog data from sensors in the industrial process, such as temperature and pressure sensors. The P0923NG can then use this data to generate appropriate output signals to control actuators. In a chemical production line, the FBM201 senses the temperature of a reaction and the P0923NG adjusts the cooling water flow by controlling a valve actuator.

- FOXBORO CP40B Controller: The CP40B controller can communicate with the P0923NG. It sends control commands based on the overall process requirements to the P0923NG, which then executes these commands by sending out the corresponding output signals. In a large – scale industrial automation system, the CP40B manages the high – level control strategy, and the P0923NG is responsible for the low – level output control, forming a complete and efficient control loop.

- FOXBORO FCM10E Fieldbus Communication Module: The FCM10E module enhances the communication capabilities of the P0923NG. It can convert and manage data between different fieldbus protocols, allowing the P0923NG to communicate effectively with other devices in a complex industrial network. In a multi – vendor industrial control system, the FCM10E enables seamless data exchange between the P0923NG and other components, ensuring smooth operation of the entire system.

- FOXBORO Power Supplies: To ensure stable power supply to the P0923NG, FOXBORO power supplies are a perfect match. They provide the required 24V DC power with high stability, protecting the module from power fluctuations. In an industrial environment where power grid instability is common, these power supplies safeguard the reliable operation of the P0923NG, minimizing the risk of malfunctions due to power issues.

- FOXBORO HMI (Human – Machine Interface) Devices: HMI devices from FOXBORO can be integrated with the P0923NG. Operators can use these HMIs to monitor the status of the output signals controlled by the P0923NG and adjust the control parameters. In a manufacturing plant, operators can use the HMI to view the status of robotic arm control signals output by the P0923NG and make on – the – fly adjustments to optimize the production process.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0923NG is a straightforward process. Its compact size and clear labeling make it easy to fit into standard control cabinets. The connection terminals are designed for quick and secure wiring, allowing technicians to complete the installation in a relatively short time. Before installation, ensure that the working environment meets the specified temperature and humidity requirements.

For maintenance, the P0923NG has built – in diagnostic functions. LEDs on the module indicate the status of power, communication, and output channels. In case of a fault, the modular design allows for quick replacement. FOXBORO offers a wide range of high – quality spare parts, and their technical support team is available 24/7 to provide remote or on – site assistance. Regular firmware updates are also provided to enhance the module’s performance and compatibility with new industrial technologies. With proper installation, maintenance, and support, the P0923NG can provide long – term reliable service in industrial control systems.

For maintenance, the P0923NG has built – in diagnostic functions. LEDs on the module indicate the status of power, communication, and output channels. In case of a fault, the modular design allows for quick replacement. FOXBORO offers a wide range of high – quality spare parts, and their technical support team is available 24/7 to provide remote or on – site assistance. Regular firmware updates are also provided to enhance the module’s performance and compatibility with new industrial technologies. With proper installation, maintenance, and support, the P0923NG can provide long – term reliable service in industrial control systems.