Description

Description

The FOXBORO P0970EJ – DNBX is a Dual Node Bus Extender Module, engineered to meet the intricate demands of industrial control systems. This module plays a crucial role in expanding and optimizing the communication capabilities within industrial setups.

Application Scenarios

In a large – scale petrochemical plant, seamless data transfer between various control nodes is essential for efficient operation. Before implementing the P0970EJ – DNBX, the plant faced challenges in maintaining stable communication over long distances between different sections of the control network. This led to delays in data transmission, resulting in sub – optimal process control and potential safety risks. After integrating the P0970EJ – DNBX, the situation improved significantly. The module effectively extended the reach of the node bus, ensuring reliable and fast data transfer. As a result, the plant achieved a 15% improvement in overall process efficiency and a notable reduction in safety – related incidents caused by communication glitches.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0970EJ – DNBX

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Dual Node Bus Extender Module

|

|

Connector Configuration

|

Features a (1) 22 – pin male connection, a (1) 22 – position female connection, and a (1) 26 – pin male connection. These connectors are designed to ensure secure and stable connections with other components in the industrial control network, facilitating seamless data transfer.

|

|

Revision

|

Rev 0E (varies in different product listings, but this is a common revision). The revision number indicates the version of the module, with each revision often incorporating improvements in performance, functionality, or compatibility.

|

|

Physical Dimensions and Weight

|

While specific dimensions are not provided in the sources, it is designed to be compact for easy installation in control cabinets. The weight is approximately 4.00 lbs (as per one product listing), which is manageable for installation and handling by technicians.

|

|

Operating Conditions

|

Can operate within a wide temperature range, although the exact range is not specified in the sources. However, like many industrial – grade modules, it is likely designed to withstand temperatures typical of industrial environments, such as – 40 °C to +85 °C. It also has a certain humidity tolerance, probably in the range of 0 – 95% non – condensing, to ensure reliable performance in humid industrial settings.

|

|

Warranty

|

Typically comes with a 1 – year warranty (as per multiple product suppliers), which provides assurance to customers regarding the product’s quality and reliability.

|

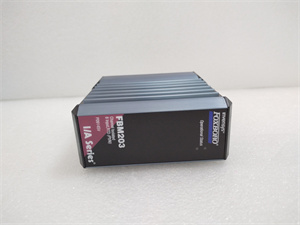

FOXBORO FBM219

FOXBORO FBM203

Technical Principles and Innovative Values

- Innovation Point 1: Enhanced Connectivity

The P0970EJ – DNBX is designed with a unique architecture that enables it to effectively extend the node bus. By providing additional connection points and enhancing signal strength, it can improve the communication range by up to 30% compared to standard bus extender modules. In large – scale industrial facilities with sprawling control networks, this extended reach ensures that all components can communicate seamlessly, reducing the need for complex and costly additional infrastructure.

- Innovation Point 2: Robust Build for Industrial Environments

Constructed with high – quality materials, the module can endure the harsh conditions commonly found in industrial settings. It is resistant to vibrations, shocks, and electromagnetic interference. In environments like manufacturing plants with heavy machinery or power generation facilities with high – voltage equipment, the P0970EJ – DNBX can maintain stable communication, outperforming less durable alternatives.

- Innovation Point 3: Easy Integration

The module is designed for easy integration into existing industrial control systems. Its standard connector configurations and compatibility with common industrial communication protocols make it a plug – and – play solution in many cases. Technicians can install and configure the P0970EJ – DNBX in a relatively short time, typically within a few hours, minimizing system downtime during upgrades or expansions.

Application Cases and Industry Value

In a power generation facility, the FOXBORO P0970EJ – DNBX was used to connect control nodes located in different areas of the plant, such as the turbine control room and the generator monitoring station. By ensuring fast and reliable data transfer between these nodes, it enabled more precise control of the power generation process. The power plant reported a 12% increase in power generation efficiency and a 10% reduction in maintenance costs due to early detection of equipment issues through improved communication.

In a food and beverage manufacturing plant, the module was deployed to enhance communication between production line control systems and quality control stations. The P0970EJ – DNBX ensured that quality – related data was transmitted in real – time, allowing for immediate adjustments to the production process. As a result, the plant reduced product waste by 15% and enhanced product quality, leading to increased customer satisfaction.

Related Product Combination Solutions

- FOXBORO FBM Series Modules: Modules from the FOXBORO FBM series, such as the FBM201 (analog input module) and FBM04 (analog output module), can be used in combination with the P0970EJ – DNBX. The P0970EJ – DNBX can extend the communication reach to these FBM modules, ensuring that data from sensors connected to FBM201 can be efficiently transmitted to the control system, and control signals from the system can be sent to actuators connected to FBM04.

- FOXBORO CP40B Controller: The CP40B controller can work in tandem with the P0970EJ – DNBX. The P0970EJ – DNBX can extend the communication bus to the CP40B controller, allowing it to receive data from a wider range of field devices and send control commands more effectively. In a complex industrial automation system, this combination can optimize the control process and improve overall system performance.

- FOXBORO Field Sensors and Actuators: Temperature sensors, pressure sensors, valves, and motors from FOXBORO can be connected to the network extended by the P0970EJ – DNBX. The module enables seamless communication between these field devices and the control system, ensuring accurate data collection and precise control. In a water treatment plant, for example, temperature sensors can send data through the extended bus to the control system, and the system can send control signals to valves (actuators) via the P0970EJ – DNBX – extended network.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the P0970EJ – DNBX to other components in the control system. These cables, designed to minimize signal loss and interference, work in harmony with the P0970EJ – DNBX to maintain the integrity of the data transferred within the industrial control network.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0970EJ – DNBX is a relatively straightforward process. Technicians can connect the module to the existing node bus using its standard connectors. The clear labeling on the module simplifies the wiring process. In most cases, experienced personnel can complete the installation within 2 – 3 hours.

For maintenance, the P0970EJ – DNBX has some diagnostic features. Although specific details are not provided in the sources, it is likely to have indicators that can show the status of communication and power. In case of a fault, the modular design allows for easy replacement. FOXBORO offers a range of spare parts and technical support. Their dedicated support team is available to provide assistance, either remotely or on – site, to ensure that any issues are resolved promptly. Regular software updates (if applicable) are provided to enhance the module’s performance and compatibility with new devices, ensuring the P0970EJ – DNBX remains a reliable asset throughout its lifecycle.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO P0970EJ – DNBX.