Description

Product Overview

The GE 269 PLUS-D/O-100P-125V is a digital motor relay device that hails from the esteemed GE Multilin 269 plus motor management relay series. This series is well – known for its reliability and comprehensive functionality in the industrial motor protection domain. The 269 PLUS-D/O-100P-125V is specifically designed to safeguard and optimize the performance of medium – sized motor systems, playing a crucial role in ensuring the smooth operation of industrial processes that rely on such motors.

This device is equipped with advanced features to monitor the electrical and thermal conditions of 3 – phase AC motors. It uses current transformers and thermal detectors as its primary means of data collection. In the face of potential threats like overloads or other fault conditions, the GE 269 PLUS-D/O-100P-125V steps in promptly. It can trigger an alarm to notify operators of impending issues or, if necessary, trip the motor to prevent any further damage. Its presence in an industrial automation system adds a layer of protection, reducing the risk of unexpected motor failures and subsequent production disruptions.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 269 PLUS-D/O-100P-125V |

| Manufacturer | General Electric |

| Product Type | Digital Motor Relay |

| Power Supply Voltage | 125 VDC |

| Operating Temperature Range | – 40 °C to + 70 °C |

| Protection Type | Digital Motor Management |

| Contact Rating | 100 P |

| Relay Type | DO – Dry Contact Output |

| Relay Material | High – grade brass and copper alloys |

| Dimensions (WxHxD) | 76 mm x 76 mm x 100mm |

| Weight | 0.3 kg |

| Software | Enervista 269 |

| User Manual | 1601 – 0013 – E4 |

| Altitude Rating | 2000m IEC 1010 – 1 |

| Impulse Test | IEC 255 – 5 0.5 joule 5kv |

| Running Hours Counter Accuracy | ± 1 % |

Main Features and Advantages

Precise Thermal Monitoring

The GE 269 PLUS-D/O-100P-125V comes with 100 ohm platinum RTD (resistance temperature detectors). These detectors are highly accurate, enabling the device to precisely monitor the thermal conditions of the motor. By closely tracking the temperature, it can effectively protect the motor from thermal overloads, a common cause of motor failure. This ensures the longevity of the motor and reduces maintenance costs associated with overheating issues.

Programmable Overload Curves

Featuring eight programmable overload curves, this relay can be customized to meet the specific requirements of each motor. Operators can set these curves to match the current draw of the motor. This customization ensures that the device trips the motor in case of a genuine overload while minimizing the occurrence of false trips. Additionally, the Flex Curve (TM) function option offers even greater customization, allowing users to create unique curves tailored to their motor’s specific needs.

User – Friendly Interface

With a 12 – key pad and a simple LED display on the front, programming the 269 PLUS-D/O-100P-125V is quick and straightforward. The LED display provides real – time information about the motor’s status and the relay’s operation. This makes it easy for operators to diagnose and troubleshoot any issues that may arise, enhancing the overall efficiency of motor management.

Durable Construction

Built with a case that is resilient against corrosion and flames, and meeting IP40x standards, the GE 269 PLUS-D/O-100P-125V is designed to withstand harsh industrial environments. The display can show up to 48 characters during alarms or trips, and it has four status indicators with corresponding LEDs to clearly indicate output activation, providing operators with valuable information at a glance.

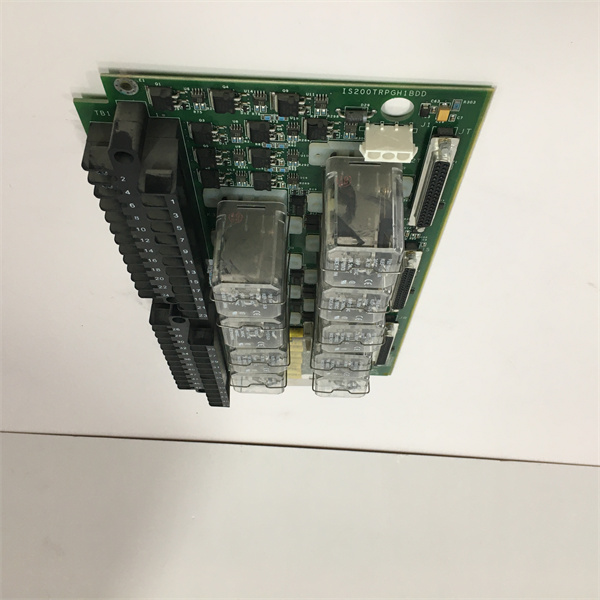

IS220PDIAH1A

Application Field

Manufacturing Plants

In manufacturing settings, medium – sized motors are used in a variety of equipment such as conveyor belts, pumps, and machine tools. The GE 269 PLUS-D/O-100P-125V can be installed to protect these motors. For example, in a food manufacturing plant, motors powering conveyor belts that transport products need to operate continuously. The 269 PLUS-D/O-100P-125V can monitor the motors, ensuring they don’t overheat due to continuous operation or sudden jams, preventing production stoppages.

Power Generation Facilities

Power plants use numerous medium – sized motors for tasks like cooling water circulation, ash handling, and coal pulverization. The GE 269 PLUS-D/O-100P-125V can safeguard these motors from electrical and thermal faults. In a coal – fired power plant, motors used in the coal pulverization process are subject to high stress. The relay can detect any abnormal conditions in these motors, protecting them and maintaining the smooth operation of the power generation process.

Water Treatment Plants

Motors in water treatment plants are responsible for functions such as pumping water, running filtration systems, and aerating water. The 269 PLUS-D/O-100P-125V can be employed to protect these motors. In a large – scale water treatment facility, motors driving pumps that transfer water between different treatment stages need to be reliable. The relay can prevent motor failures, ensuring the uninterrupted treatment of water and the delivery of clean water to consumers.

Related Products

- GE 269 PLUS-D/O-287-100P-240: Similar to the 269 PLUS-D/O-100P-125V, it is also a motor management relay in the 269 plus series. However, it has a different voltage rating (240V compared to 125V of the 269 PLUS-D/O-100P-125V) and may be suitable for applications with different power requirements.

- GE 269 PLUS-120N-125VDC: This model also belongs to the 269 plus series. It likely has different features such as contact ratings or input/output configurations compared to the 269 PLUS-D/O-100P-125V, making it suitable for other specific motor protection scenarios.

- GE Multilin 269: The base model of the series, on which the 269 PLUS-D/O-100P-125V is an advanced version. The 269 may lack some of the more specialized features like the extensive programmable options of the 269 PLUS-D/O-100P-125V.

- GE IC697ACC722B: A processor module by GE. While the 269 PLUS-D/O-100P-125V focuses on motor protection, the IC697ACC722B is involved in overall system processing. They can work together in an industrial setup, with the relay providing motor – related data to the processor for overall system control.

- GE D20 – PS high – voltage AC/DC power supply: This power supply can be used to power the GE 269 PLUS-D/O-100P-125V or other related devices in the industrial system, ensuring stable power input for the relay’s proper functioning.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 269 PLUS-D/O-100P-125V, ensure that the installation area is clean and free from excessive dust, moisture, and strong electromagnetic interference. Verify that the power supply voltage is a stable 125 VDC, as any voltage fluctuations can affect the relay’s performance. Mount the relay in a location where the front – panel keypad and display are easily accessible for programming and monitoring. Check the compatibility of the relay with the motor and other connected devices in the system.

Maintenance recommendations: Regularly inspect the GE 269 PLUS-D/O-100P-125V for any signs of physical damage, such as cracks in the case or loose connections. Monitor the status LEDs on the front panel to quickly identify any abnormal conditions. Periodically clean the relay to prevent dust accumulation, which could potentially affect its heat dissipation. Update the software (Enervista 269) when new versions are available to ensure optimal performance and access to the latest features. If any faults occur, refer to the user manual (1601 – 0013 – E4) for troubleshooting steps.

Product Guarantee

General Electric stands firmly behind the quality of the GE 269 PLUS-D/O-100P-125V. The product undergoes strict quality control during manufacturing to ensure it meets the highest industry standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a query about programming the overload curves or troubleshooting a fault, GE’s experts are committed to ensuring the 269 PLUS-D/O-100P-125V operates smoothly, providing customers with peace of mind and confidence in their investment.