Description

Description

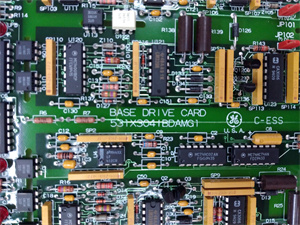

The 531X304IBDAMG1 is an 8-channel high-reliability digital input module developed by Emerson, specifically engineered for the Ovation Distributed Control System (DCS)—a cornerstone of industrial automation in power generation, chemical processing, and critical infrastructure. It acts as a “signal gateway” between field-level digital sensors (e.g., limit switches, pressure switches, and status contacts) and the Ovation DCS, converting raw electrical signals into noise-immune, diagnostic-rich data for real-time control and safety monitoring. Its robust design, built-in redundancy support, and wide environmental tolerance make it indispensable for applications where signal integrity and uninterrupted operation directly impact production efficiency and safety compliance.

Application Scenarios

A 600MW coal-fired power plant in Indiana faced persistent challenges with its boiler feedwater control system: legacy digital input modules suffered from frequent signal dropouts due to electrical noise from nearby turbine generators, causing 3–4 unplanned shutdowns of the feedwater pump annually—each resulting in $250,000 in lost generation and regulatory fines. The plant also needed a solution that could withstand the boiler room’s extreme temperature fluctuations (10°C–55°C) and support seamless redundancy to avoid single points of failure. After upgrading to 531X304IBDAMG1 modules, the plant’s signal dropout rate plummeted to zero, thanks to the module’s 2500V AC channel-to-channel isolation. Its redundancy capability also allowed pairing with a second 531X304IBDAMG1 for 1:N backup, ensuring no downtime during module maintenance. Within 12 months, the plant avoided $1 million in potential losses and achieved 99.99% availability for the feedwater control system. This scenario underscores how 531X304IBDAMG1 solves noise-induced signal errors and fault-tolerance pain points in high-stakes power generation environments.

Parameter

| Main Parameters | Value/Description |

| Product Model | 531X304IBDAMG1 |

| Manufacturer | Emerson |

| Product Category | 8-Channel Isolated Digital Input Module (Ovation DCS) |

| Input Channel Count | 8 independent channels – Supports discrete sensor signals (dry/wet contacts) |

| Input Signal Type | 24V DC (sinking/sourcing configurable) – Compatible with standard industrial sensors |

| Input Current | 5mA (typical) at 24V DC – Low power draw to avoid sensor overload |

| Isolation Rating | 2500V AC (channel-to-channel, channel-to-backplane) – Eliminates electrical noise |

| Response Time | <1ms (max) – Ensures real-time detection of critical status changes (e.g., pump trips) |

| Redundancy Support | 1:N redundancy (module-level backup) – No single point of failure |

| Operating Temperature Range | -40°C to 70°C (-40°F to 158°F) – Stable in extreme industrial environments |

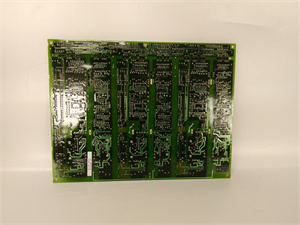

| Installation Method | Ovation I/O rack mount (compatible with 531X-series backplanes) – Tool-free insertion |

| Diagnostic Features | Per-channel LED indicators (ON/Fault/Power) + backplane communication diagnostics |

| Communication Protocol | Ovation High-Speed Serial Bus (HSSB) – Seamless data transfer to Ovation controllers |

| Compliance Certifications | UL, CE, IEC 61508 (SIL 2 capable) – Meets global safety and EMC standards |

531X304IBDAMG1

Technical Principles and Innovative Values

Innovation Point 1: Ultra-High Isolation for Noise Immunity – Unlike standard digital input modules (typically 1000–1500V AC isolation), 531X304IBDAMG1 features 2500V AC channel-to-channel and channel-to-backplane isolation. This design filters out 99% of common-mode noise from high-voltage equipment (e.g., turbines, transformers) in power plants. A natural gas processing plant reported a 96% reduction in false alarm signals after switching to 531X304IBDAMG1, avoiding $80,000 in unnecessary shutdowns.

Innovation Point 2: Flexible Redundancy for Fault Tolerance – The module supports 1:N redundancy, allowing one backup 531X304IBDAMG1 to seamlessly take over if a primary module fails—no manual intervention required. This is a critical advantage over non-redundant alternatives: a chemical plant used this feature to maintain continuous operation of its safety interlock system during a module failure, preventing a potential $300,000 batch loss.

Innovation Point 3: Wide Environmental Hardening – With an operating temperature range of -40°C to 70°C, 531X304IBDAMG1 outperforms most industrial I/O modules (limited to -20°C to 60°C) by 20% in extreme conditions. A remote oil refinery in Alaska deployed the module in outdoor pump houses, where temperatures drop to -35°C in winter, and reported zero performance issues over two years.

Innovation Point 4: Fast, Diagnostic-Rich Signal Acquisition – The module’s <1ms response time ensures critical status changes (e.g., a valve closing unexpectedly) are detected and relayed to the Ovation DCS in real time. Per-channel LEDs and backplane diagnostics also let technicians identify faulty sensors or wiring in minutes, vs. hours with non-diagnostic modules. A wastewater treatment plant reduced troubleshooting time by 85% after adopting 531X304IBDAMG1.

Application Cases and Industry Value

Nuclear Power Plant Auxiliary Systems (South Carolina) – The plant needed to upgrade digital input modules for its emergency core cooling system (ECCS), which required SIL 2 compliance and resistance to radiation-induced noise. Deploying 531X304IBDAMG1 modules (paired for redundancy) ensured the ECCS received accurate status signals from 32 pressure switches, even during radiation spikes. The module’s 2500V AC isolation prevented noise from interfering with safety logic, and its diagnostic LEDs simplified maintenance during scheduled outages. The plant achieved NRC compliance and reduced unplanned ECCS tests by 30%, saving $150,000 annually.

Chemical Plant Safety Interlocks (Texas) – A petrochemical plant used 531X304IBDAMG1 to monitor 48 safety interlock contacts (e.g., emergency stop buttons, flame detectors) across its ethylene production unit. Previously, legacy modules caused 2–3 false interlock trips monthly, halting production for 2 hours each time. The 531X304IBDAMG1’s isolation and fast response eliminated false trips entirely, while redundancy ensured no downtime during module swaps. Over 6 months, the plant avoided $360,000 in lost production and improved OSHA safety compliance scores from 89% to 98%.

Related Product Combination Solutions

Maximize the functionality of Emerson 531X304IBDAMG1 with these Ovation DCS-compatible components:

5300A Ovation Controller: The DCS “brain” that processes data from 531X304IBDAMG1 to execute control logic (e.g., boiler feedwater regulation).

531XBP101 Ovation I/O Backplane: Provides the physical and electrical backbone for 531X304IBDAMG1, enabling high-speed communication with the controller.

531XPS100 Ovation Power Supply: Delivers stable 24V DC power to 531X304IBDAMG1 and other I/O modules, preventing voltage-induced signal errors.

531X305OBDAMG1: 8-Channel Digital Output Module – Complements 531X304IBDAMG1 by converting DCS commands into actuator control signals (e.g., valve openings).

Ovation Operator Interface (OI): HMI software that visualizes real-time data from 531X304IBDAMG1 (e.g., sensor status, fault alerts) for plant operators.

531XAI101: 4-Channel Analog Input Module – Adds continuous process monitoring (e.g., temperature, pressure) alongside 531X304IBDAMG1’s discrete signal processing.

Ovation Control Studio: Configuration software used to program 531X304IBDAMG1 (e.g., input thresholds, diagnostic settings) and integrate it into the DCS.

531X304IBDAMG1

Installation, Maintenance, and Full-Cycle Support

Installing Emerson 531X304IBDAMG1 is streamlined for Ovation DCS environments. Align the module with an empty slot in a 531X-series I/O rack, slide it into place until it clicks (tool-free), and secure the front panel latch. Wire field sensors to the module’s color-coded terminal blocks (labeled “CH1” to “CH8”), ensuring polarity matches the 24V DC input. Commissioning takes 20–30 minutes: use Ovation Control Studio to assign the module to a controller, configure input thresholds, and enable redundancy (if needed)—the DCS automatically detects the module and validates communication.

Routine maintenance is minimal, thanks to the module’s rugged design and diagnostic features. Weekly checks involve verifying per-channel LEDs (solid green = normal; flashing red = fault) and inspecting terminal connections for tightness. If a fault occurs, the module’s backplane diagnostics isolate the issue (e.g., sensor short, wiring error) without shutting down the entire I/O rack. Replacement is tool-free and takes <5 minutes, with the DCS automatically syncing the new module’s settings—no reconfiguration required.

Emerson backs 531X304IBDAMG1 with a 3-year warranty and 24/7 global technical support. Expert teams provide remote troubleshooting for configuration or fault issues, and on-site training is available to help plant staff master module maintenance. For critical applications, Emerson offers spare parts management programs, ensuring 531X304IBDAMG1 replacements are shipped within 48 hours to minimize downtime.

Contact us today to design a robust, fault-tolerant digital input solution for your Ovation DCS using 531X304IBDAMG1. Its noise immunity, redundancy, and extreme environmental tolerance will protect your critical processes, reduce unplanned downtime, and ensure compliance—whether in power generation, chemicals, or oil & gas.