Description

Product Overview

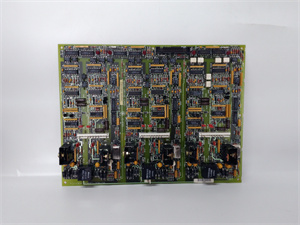

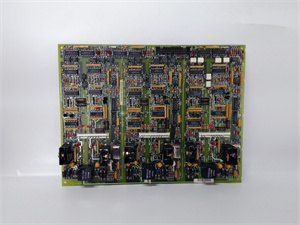

The GE 531X304IBDARG1 is a crucial PC base Drive Card within GE’s industrial control product lineup. As a fundamental component in the company’s drive systems, it plays a significant role in enabling seamless communication and control within complex industrial setups.

Equipped with three crystal oscillators, the 531X304IBDARG1 can generate precise frequencies. These oscillators utilize crystals of various sizes and shapes to produce high – pitched and extremely accurate frequencies, which are essential for the stable operation of the card and the systems it interfaces with. It features five male ports that serve as gateways for communication between the 531X304IBDARG1 and other circuit boards in the system. This connectivity allows for the efficient transfer of data and control signals, ensuring coordinated operation of different components. Integrated circuits (ICs), also known as microchips or chips, are embedded in the 531X304IBDARG1. These ICs are responsible for defining the board’s purpose, functions, and its communication protocols with other boards. Additionally, the card uses capacitors to store energy, which can be released as needed during the operation of the industrial system. When the need to dissipate energy arises, the card’s various resistors come into play, converting the energy into heat that can be easily dissipated. Jumper ports are also present on the 531X304IBDARG1, enabling the creation or closure of smaller energy circuits around the board, adding to its flexibility in different industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 531X304IBDARG1 |

| Manufacturer | GE |

| Product Type | PC base Drive Card |

| Oscillator Quantity | Three |

| Communication Ports | Five male ports |

| Energy Storage Components | Capacitors |

| Energy Dissipation Components | Resistors |

| Integrated Circuit Usage | For function and communication definition |

| Jumper Ports | Present for circuit configuration |

| Operating Voltage | [Refer to specific GE documentation, typically within a standard industrial range] |

| Operating Temperature | [Check GE’s official product manual for the exact range] |

| Physical Dimensions | Compact for easy integration in industrial cabinets |

| Weight | [Exact weight details can be found in the product manual] |

531X304IBDARG1

Main Features and Advantages

Precise Oscillation – based Timing

The three crystal oscillators in the 531X304IBDARG1 ensure highly accurate timing. In industrial applications where precise synchronization of operations is crucial, such as in high – speed manufacturing lines or complex chemical processes, this feature enables the card to provide the necessary timing signals. For example, in a manufacturing plant with multiple automated machinery operating in sequence, the accurate frequencies generated by the oscillators help in coordinating the movement of conveyors, robotic arms, and other equipment, minimizing errors and improving overall productivity.

Versatile Connectivity

With its five male ports, the 531X304IBDARG1 offers extensive connectivity options. It can interface with a wide variety of other circuit boards within an industrial control system. This versatility allows for seamless integration into both existing and new industrial setups. Whether it’s connecting to sensors for data input, actuators for control output, or other processing boards, the card can adapt to different communication requirements, enhancing the overall functionality of the industrial network.

Energy Management Capabilities

The use of capacitors for energy storage and resistors for energy dissipation gives the 531X304IBDARG1 efficient energy management capabilities. In industrial environments where power fluctuations can occur, the capacitors can store excess energy during peak power availability and release it during low – power periods, ensuring stable operation of the card and the connected devices. The resistors, on the other hand, help in safely dissipating any unwanted energy, protecting the components on the card from potential damage due to over – voltage or energy surges.

Configurable Circuitry

The presence of jumper ports on the 531X304IBDARG1 allows for easy configuration of smaller energy circuits. This is beneficial in scenarios where the industrial application requires specific electrical pathways to be set up or modified. For instance, in a custom – designed industrial control panel, technicians can use the jumper ports to create unique circuit connections that meet the specific control requirements of the machinery, providing a cost – effective and flexible solution for different industrial needs.

531X304IBDARG1

Application Field

Manufacturing Industry

In manufacturing plants, the GE 531X304IBDARG1 is widely used. It can be found in automated production lines, where it controls the operation of various machinery. For example, in an automotive manufacturing facility, it can be used to control the movement of robotic arms during the assembly process. The precise timing provided by its crystal oscillators ensures that the robotic arms move with high accuracy, picking and placing car parts at the right time and in the correct position. In a textile manufacturing plant, the card can be used to control the speed and operation of spinning machines and looms. The versatile connectivity of the 531X304IBDARG1 allows it to communicate with sensors that monitor thread tension, fabric quality, and machine status, enabling real – time adjustments to optimize production.

Process Industries

Industries such as chemical, oil and gas, and food and beverage rely on the 531X304IBDARG1 for process control. In a chemical plant, the card can be part of the control system that manages chemical reactions. It can interface with sensors that measure temperature, pressure, and chemical composition, and based on the data received, it can control valves, pumps, and other equipment to ensure the reactions proceed smoothly. In an oil refinery, the 531X304IBDARG1 can be used to control the flow of crude oil and refined products through pipelines. The energy management capabilities of the card are particularly useful in these industries, where continuous and stable operation is essential, and power fluctuations can have significant impacts on the production process.

Power Generation

In power generation facilities, the 531X304IBDARG1 plays a role in controlling and monitoring equipment. For example, in a power plant, it can be used to control the operation of turbines. The card can receive data from sensors that monitor the speed, temperature, and vibration of the turbines and adjust the control signals to ensure the turbines operate at optimal efficiency. The configurable circuitry of the 531X304IBDARG1 allows for customization according to the specific requirements of different power generation systems, whether they are based on fossil fuels, renewables, or nuclear energy.

Related Products

GE 531X304IBDASG1

This is also a basic drive card from GE. Similar to the 531X304IBDARG1, it is used in GE’s drive systems. However, the 531X304IBDASG1 might have different physical designs or specific functional optimizations. It has a surface with codes like 006/09 and C – ess and is designed with components such as transformers, vertical pin – type connectors, and parallel radiators in its internal structure.

GE 531X303MCPARG1

It is an AC power board. Unlike the 531X304IBDARG1 which focuses on drive – related functions, the 531X303MCPARG1 is mainly responsible for providing AC power within the industrial system. It is often used in older GE – released general – purpose drive systems, including the DC – 300 drive, and is designed to be placed along the edge of the circuit board.

GE F31X304IBDAMG1

This is related to the 531X304IBDARG1 as the 531X304IBDARG1 is its auxiliary board. The F31X304IBDAMG1 serves as the main board in a specific configuration, and the 531X304IBDARG1 complements its functions. They work together within GE’s drive system architecture to achieve comprehensive drive – related operations.

GE 531X305NTBANG1

While the 531X304IBDARG1 is a drive – card, the 531X305NTBANG1 may have different functions, perhaps related to network or signal transmission within the industrial control system. It could be used in scenarios where the 531X304IBDARG1 – controlled equipment needs to communicate with other parts of the network, but further details would be available in GE’s product documentation.

GE 531X307LTBAHG1

This product might have a role in a different aspect of the industrial setup compared to the 531X304IBDARG1. It could be involved in functions such as signal conditioning or control in a more specialized area of the industrial process. The exact relationship and differences can be better understood by referring to GE’s detailed product specifications and application notes.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 531X304IBDARG1, ensure that the industrial control system is powered off. Thoroughly clean the installation area to prevent dust or debris from interfering with the card’s operation. Check the compatibility of the 531X304IBDARG1 with other components in the system, referring to GE’s official compatibility charts. Verify that the connectors and ports on the card and the target system are free from damage. Mount the card securely in the designated slot or location, following the installation guidelines provided in the product manual to ensure proper electrical connections.

Maintenance recommendations: Regularly inspect the 531X304IBDARG1 for any signs of physical damage, such as cracked components or loose connections. Monitor the card’s performance by checking for any abnormal communication patterns or energy consumption. Clean the card gently, if necessary, using a static – free brush to remove any accumulated dust. Periodically review and update the card’s configuration settings, especially when there are changes in the industrial process or system requirements. If any issues are detected, consult GE’s technical support or the product’s troubleshooting guide for appropriate solutions.

Maintenance recommendations: Regularly inspect the 531X304IBDARG1 for any signs of physical damage, such as cracked components or loose connections. Monitor the card’s performance by checking for any abnormal communication patterns or energy consumption. Clean the card gently, if necessary, using a static – free brush to remove any accumulated dust. Periodically review and update the card’s configuration settings, especially when there are changes in the industrial process or system requirements. If any issues are detected, consult GE’s technical support or the product’s troubleshooting guide for appropriate solutions.

Product Guarantee

GE stands firmly behind the quality of the 531X304IBDARG1. The card is manufactured using high – quality materials and undergoes rigorous testing to meet strict industry standards. GE offers a standard warranty period for the 531X304IBDARG1, during which, if the card experiences any defects in materials or workmanship, GE will provide repair or replacement services free of charge. Their team of experienced technical support professionals is available to assist customers with any installation, operation, or maintenance questions. GE’s commitment to quality and after – sales service ensures that customers can rely on the 531X304IBDARG1 for long – term, reliable performance in their industrial applications, giving them peace of mind and confidence in their investment.