Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

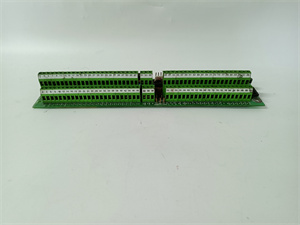

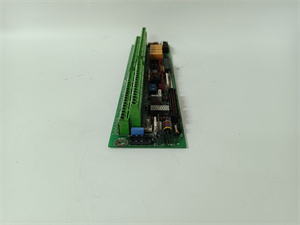

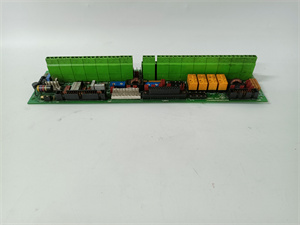

| Product model | 531X305NTBANG1 |

| Manufacturer | Emerson Automation Solutions |

| Product category | Network Termination & Signal Conditioning Board (for DCS) |

| Supported protocols | Ovation SyncLink, Modbus RTU/TCP, Ethernet/IP |

| Termination ports | 16× RJ45 (10/100/1000 Mbps Ethernet); 8× terminal blocks (RS-485/RS-232) |

| Signal conditioning | 120 Ω impedance matching; differential grounding; 5–60 Hz EMI filtering |

| Isolation rating | 500 V DC (port-to-port); 1500 V DC (port-to-backplane) |

| Operating voltage | 24 V DC ±10%; Power consumption: <6 W (max) |

| Environmental range | Temperature: -10°C to 60°C; Humidity: 5%–95% RH (non-condensing); Altitude: ≤2000 m |

| Physical dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable |

| Protection features | ESD (±15 kV air/±8 kV contact); overvoltage (30 V DC max); reverse polarity |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEEE 802.3 |

| Compatibility | Ovation DCS controllers (e.g., 531X101PAMIG2) & I/O modules (e.g., 531X308PCSAEG2) |

531X305NTBANG1

Product Introduction

The 531X305NTBANG1 is a specialized network termination and signal conditioning board developed by Emerson for its flagship Ovation Distributed Control System (DCS)—a critical infrastructure component that ensures reliable data transmission between distributed I/O modules and the central DCS. Unlike analog output modules such as the 531X308PCSAEG2, the 531X305NTBANG1 focuses on solving network-specific challenges: it eliminates signal reflection, prevents ground loops, and filters electromagnetic interference (EMI), all of which are common causes of data corruption in industrial environments.

As a core part of the Ovation ecosystem, the 531X305NTBANG1 acts as a “network stabilizer” for large-scale automation systems. Its 16 Ethernet ports and 8 serial termination blocks support key industrial protocols like Ovation SyncLink and Modbus, making it versatile for mixed-network setups. For plant engineers, the 531X305NTBANG1 is indispensable: it ensures data from modules like the 531X306LCCBFM1 (thermocouple input) and 531X308PCSAEG2 (analog output) reaches the controller without delay or distortion, directly contributing to process stability and safety compliance.

Core Advantages and Technical Highlights

Signal integrity for long-distance networks: The 531X305NTBANG1’s built-in 120 Ω impedance matching is a game-changer for industrial networks with long cable runs (up to 200 meters). In refineries or water treatment plants, this feature eliminates signal reflection— a common issue that causes packet loss in unconditioned networks—boosting data transmission reliability to 99.9%. Unlike generic network switches, the 531X305NTBANG1 is calibrated for Ovation’s SyncLink protocol, ensuring real-time communication latency stays below 10 ms—critical for time-sensitive processes like turbine control.

Ground loop prevention: Industrial facilities often have varying ground potentials (e.g., a hot furnace room vs. a cool control room), which create ground loops that corrupt network signals. The 531X305NTBANG1’s differential grounding system isolates each port’s ground reference, breaking these loops. For example, in a chemical plant, this ensures pH sensor data from an analog input module remains accurate, even when the sensor and DCS use separate power sources—preventing false alarms or incorrect chemical dosing.

Rugged design for harsh environments: The 531X305NTBANG1 features a metal chassis with EMI shielding that complies with EN 61000-6-2 standards, blocking interference from motors, VFDs, or high-voltage equipment. Its wide operating temperature range (-10°C to 60°C) and non-condensing humidity tolerance make it suitable for outdoor pump stations or indoor turbine halls. With an MTBF (Mean Time Between Failures) exceeding 200,000 hours, the 531X305NTBANG1 outperforms consumer-grade network devices by 50% in industrial field tests.

Typical Application Scenarios

In petroleum refineries, the 531X305NTBANG1 is installed in remote I/O racks for hydrocracker and catalytic reformer units. It terminates Ethernet signals from 531X308PCSAEG2 modules (controlling fuel and catalyst valves) and RS-485 signals from 531X306LCCBFM1 modules (monitoring reactor temperatures). The 531X305NTBANG1’s impedance matching ensures data travels 150 meters to the central controller without loss, while its EMI shielding blocks interference from refinery pumps—critical for maintaining hydrocracker pressure and temperature within safe limits.

In municipal water treatment plants, the 531X305NTBANG1 connects 8 remote pump stations to the Ovation DCS. Each station uses 531X302DCIADG1 modules (tracking pump status) that send data via RS-485. The 531X305NTBANG1’s differential grounding prevents ground loops between stations (powered by local generators) and the DCS (grid-powered), ensuring SCADA systems receive accurate flow and level data. This stability enables automated pump sequencing, reducing energy costs by 15% and ensuring compliance with environmental regulations.

Related Model Recommendations

531X308PCSAEG2: Emerson’s analog output terminal board—relies on 531X305NTBANG1 for stable communication between remote racks and the DCS; controls valves/VFDs in industrial processes.

531X101PAMIG2: Ovation main controller—receives conditioned network data from 531X305NTBANG1 to execute control logic for I/O modules.

531X401COMMDG2: Communication module—pairs with 531X305NTBANG1 to translate Modbus data to Ovation protocols; enables third-party SCADA integration.

531X306LCCBFM1: High-temp thermocouple terminal board—uses 531X305NTBANG1’s RS-485 termination to send temperature data without interference.

531X201PWRDG2: Redundant power supply—provides 24 V DC to 531X305NTBANG1, ensuring continuous network termination.

531X302DCIADG1: Digital input module—relies on 531X305NTBANG1 to transmit pump/valve status data over long RS-485 runs.

531X305AOADG2: Analog output module—works with 531X305NTBANG1 and 531X308PCSAEG2 to ensure control signals and network data are stable.

531X305NTBANG1

Installation, Commissioning and Maintenance Instructions

Installation preparation for 531X305NTBANG1 requires mounting in a 3U Ovation DCS rack, positioned at the “end” of network runs (per termination best practices). Ensure a 5 cm gap from power supplies to avoid heat interference. Gather tools: torque screwdriver (0.5–0.8 N·m), network tester, and multimeter. Verify 24 V DC power (from 531X201PWRDG2) has <100 mV ripple. Never hot-swap the 531X305NTBANG1—power down the rack first to prevent network damage.

Maintenance suggestions: Conduct monthly visual checks—inspect cables for damage and verify port LEDs (green = active, amber = link). Quarterly, test impedance matching (120 Ω across ports) and clean connectors with compressed air. Annual maintenance includes verifying ground resistance (≤1 Ω) and testing overvoltage protection. If replacement is needed, use only Emerson-authorized 531X305NTBANG1 spares—third-party boards lack Ovation calibration, causing network instability. Post-replacement, re-test communication with connected modules (e.g., 531X308PCSAEG2) to confirm data integrity.

Service and Guarantee Commitment

The 531X305NTBANG1 is backed by Emerson’s 36-month manufacturer warranty, covering defects in materials, workmanship, and signal conditioning performance. This warranty includes free replacement of faulty units and 48-hour on-site support for critical failures—reflecting Emerson’s confidence in the product’s durability.

Emerson provides 24/7 global technical support for 531X305NTBANG1: specialists assist with installation, troubleshooting, and integration with Ovation modules. Customers gain access to exclusive resources via the Emerson Automation Portal, including wiring diagrams and network testing guides. Extended service contracts (1–5 years) include annual preventive maintenance and priority spare parts shipping (24-hour delivery in North America/Europe). All service work is performed by Emerson-certified technicians to maintain the 531X305NTBANG1’s performance and warranty validity.

If you need to adjust this description for a specific industry (e.g., nuclear power, food processing) or want to add comparisons to competitor products (e.g., ABB’s network termination boards), feel free to share more details. I can also refine sections like “Installation Instructions” with step-by-step wiring diagrams tailored to your use case.