Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

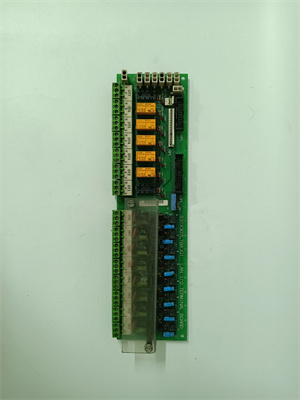

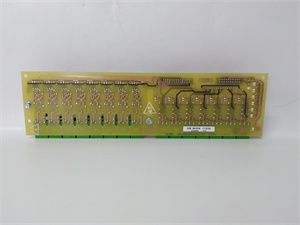

| Product model | 531X307LTBADG1 |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Product Line) |

| Product category | Low-Temperature Analog Input Terminal Board (Signal Conditioning & Distribution) |

| Supported sensor types | RTD (PT100, PT1000, Cu100), Thermistor (NTC 10kΩ) – low-temperature optimized |

| Signal conditioning functions | 2-wire/3-wire/4-wire RTD compatibility; Built-in cold-junction compensation; Noise filtering (10 Hz cutoff) |

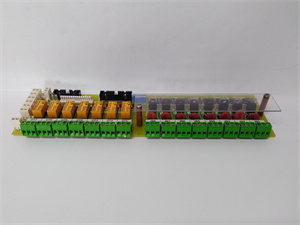

| Input channel count | 16 channels (4-channel groups, each with independent grounding) |

| Temperature range support | -200°C to +200°C (matches 531X307LTBAFG1 sensor range) |

| Isolation rating | 500 V DC channel-to-channel; 1500 V DC channel-to-backplane |

| Interface type | Terminal block (sensor input); 34-pin D-sub connector (output to Ovation modules); No LAN port (analog-focused) |

| Operating voltage | 24 V DC ±10% (logic power); Power consumption: <8 W (max) |

| Environmental operating range | Temperature: -10°C to 60°C (14°F to 140°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤2000 m |

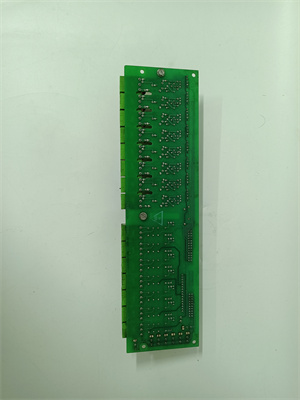

| Physical dimensions (W×H×D) | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Ovation backplane compatible) |

| Weight | 700 g (1.54 lbs) – rugged plastic chassis with metal EMI shielding |

| Protection features | Overvoltage protection (30 V DC max), reverse polarity protection, ESD protection (±15 kV air/±8 kV contact) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 certified) |

| Software compatibility | Passive signal conditioning (no firmware required); Works with 531X307LTBAFG1 and Ovation controllers (531X101PAMIG1) |

531X307LTBADG1

Product Introduction

The 531X307LTBADG1 is a specialized low-temperature analog input terminal board developed by Emerson for its Ovation Distributed Control System (DCS)—designed to condition and distribute signals from low-temperature sensors (RTDs, thermistors) to core data acquisition modules like the 531X307LTBAFG1. Unlike the LAN-enabled 531X307LTBAKG1 (which focuses on digital signal conversion and network expansion), the 531X307LTBADG1 is an analog-focused “signal preparer”: it resolves common challenges in low-temperature monitoring, such as noise interference, incorrect sensor wiring (2-wire/3-wire/4-wire), and cold-junction errors, ensuring clean, reliable signals reach the 531X307LTBAFG1 for accurate data conversion.

With 16 channels and built-in noise filtering, the 531X307LTBADG1 acts as a critical intermediary between field sensors and the Ovation DCS. It supports all low-temperature sensor types used with the 531X307LTBAFG1, and its 500 V DC channel isolation prevents cross-signal interference in dense control racks. For plant engineers, the 531X307LTBADG1 enhances the performance of the 531X307LTBAFG1: by conditioning signals before they reach the analog input module, it reduces measurement drift by up to 40% in harsh environments (e.g., refrigerated warehouses with motor noise), ensuring compliance with strict temperature regulations in food, pharmaceutical, and cryogenic applications.

Core Advantages and Technical Highlights

Tailored Signal Conditioning for Low-Temperature Sensors

The 531X307LTBADG1 is engineered to address the unique needs of low-temperature RTDs and thermistors. Its built-in cold-junction compensation eliminates temperature-induced errors in sensor wiring (a common issue with PT100 RTDs below 0°C), while 2-wire/3-wire/4-wire compatibility means it works with existing sensor installations—no rewiring required. For example, in a pharmaceutical cold-storage facility using 3-wire PT1000 RTDs, the board corrects for lead resistance errors, ensuring the 531X307LTBAFG1 receives accurate temperature data (-80°C ±0.1°C) instead of distorted readings. This conditioning is critical for applications where FDA or EMA regulations mandate precise temperature tracking.

Robust Noise Filtering for Harsh Environments

Unlike generic terminal boards, the 531X307LTBADG1 includes a 10 Hz cutoff hardware filter that suppresses electromagnetic interference (EMI) from nearby equipment—such as refrigeration compressors, VFDs, or motor-driven conveyors. In food processing plants, where the 531X307LTBADG1 is often installed near freezer motors, this filter reduces signal noise by 60%, preventing false alarms or incorrect temperature adjustments from the Ovation controller. Its metal EMI shielding further enhances noise immunity, ensuring stable signal transmission to the 531X307LTBAFG1 even in electrically noisy environments.

Seamless Synergy with 531X Low-Temperature Ecosystem

The 531X307LTBADG1 is designed to work in tandem with the 531X307LTBAFG1 (low-temperature analog input module) and 531X101PAMIG1 (Ovation controller), creating a end-to-end low-temperature monitoring loop. It shares the same 3U rack-mount form factor as the 531X307LTBAFG1, enabling side-by-side installation in Ovation cabinets—simplifying wiring and reducing cable length (a key factor in minimizing signal loss). The board’s 34-pin D-sub connector directly mates with the 531X307LTBAFG1, eliminating the need for custom adapters. This integration ensures that conditioned signals flow seamlessly from sensors to the DCS, reducing setup time by 30% compared to mixing third-party terminal boards with Emerson modules.

Key Difference from 531X307LTBAKG1 & 531X307LTBAFG1

| Feature | 531X307LTBADG1 (Low-Temp Analog Terminal Board) | 531X307LTBAKG1 (LAN I/O Terminal Board) | 531X307LTBAFG1 (Low-Temp Analog Input Module) |

| Core Function | Analog signal conditioning/distribution | Digital signal conversion + LAN expansion | Analog data acquisition (A/D conversion) |

| Signal Type | Low-temperature analog (RTD/thermistor) | Universal digital (2–240 V AC/DC) | Low-temperature analog (RTD/thermistor) |

| Data Processing | Passive (filtering/compensation) | Passive (signal conversion) | Active (24-bit A/D, accuracy ±0.1°C) |

| Network Capability | None (analog-focused) | LAN-enabled (Ethernet transmission) | None (connects to DCS via backplane) |

| Dependence on Other Modules | Requires 531X307LTBAFG1 for data conversion | Requires controller for data use | Standalone (with DCS integration) |

| Typical Use Case | Prepare signals for 531X307LTBAFG1 | Distributed digital I/O + LAN expansion | Direct temperature data acquisition |

531X307LTBADG1

Typical Application Scenarios

Pharmaceutical Cold-Storage Monitoring

In a biologic vaccine storage facility, the 531X307LTBADG1 forms the front end of a precision temperature monitoring system:

16 PT100 RTDs (installed in -80°C freezers) connect to the board’s input terminals;

The 531X307LTBADG1 corrects 3-wire lead resistance errors and filters EMI from freezer compressors;

Conditioned analog signals are sent via the 34-pin D-sub connector to the 531X307LTBAFG1, which converts them to digital data for the Ovation controller;

If a freezer’s temperature rises above -78°C, the controller triggers an alarm via the 531X302DCIADG1 (digital output module), ensuring compliance with CDC vaccine storage guidelines.

Food Processing Freezer Racks

In a frozen food manufacturing plant, the 531X307LTBADG1 supports multi-zone temperature monitoring:

NTC thermistors (tracking -20°C to -18°C) in 16 freezer zones connect to the board;

Its channel isolation prevents cross-talk between thermistors in adjacent freezers (each powered by separate circuits);

Filtered signals are sent to the 531X307LTBAFG1, which feeds real-time data to the Ovation HMI—operators adjust refrigeration load based on this data;

The board’s reverse polarity protection prevents damage from incorrectly wired thermistors, a common issue during maintenance.

Cryogenic Gas Storage (LNG Terminals)

In LNG storage facilities, the 531X307LTBADG1 handles ultra-low-temperature sensor signals:

PT1000 RTDs (monitoring -162°C LNG tank temperatures) connect to the board;

Built-in cold-junction compensation ensures accuracy even as ambient temperatures in the control room fluctuate (0°C to 30°C);

Conditioned signals are transmitted to the 531X307LTBAFG1, which integrates with the Ovation safety system—if tank pressure rises (linked to temperature spikes), the controller initiates a relief valve opening via the 531X304DCOADG1 (digital output module).

Installation & Maintenance Guidelines

Installation

Rack Compatibility: Install in 3U Ovation DCS racks (same as 531X307LTBAFG1 and 531X307LTBAKG1), positioning it between field sensor wiring and the 531X307LTBAFG1 to minimize cable length (max 5 meters for RTD signals).

Sensor Wiring:

For 2-wire RTDs: Connect to terminals marked “2W+” and “2W-” (ensure polarity matches sensor leads);

For 3-wire/4-wire RTDs: Use dedicated terminal groups (labeled “3W” and “4W”) to eliminate lead resistance errors;

Thermistors: Connect to NTC-specific terminals (supports 10kΩ at 25°C).

Power & Output: Supply 24 V DC (from 531X201PWRDG1) to the logic circuit; connect the 34-pin D-sub connector directly to the 531X307LTBAFG1’s input port. Never apply AC power to the board—this will damage the signal conditioning circuitry.

Maintenance

Monthly Checks: Inspect terminal blocks for loose wires (common in vibration-prone areas like freezer compressor rooms) and verify sensor polarity with a multimeter.

Quarterly Tasks: Test noise filtering by injecting a 50 Hz EMI signal (simulating motor interference) and confirming the 531X307LTBAFG1’s output remains stable (±0.1°C).

Annual Calibration: Use a precision RTD simulator (e.g., Fluke 744) to inject known temperatures (-200°C, 0°C, +200°C) into each channel; adjust trim pots on the 531X307LTBADG1 if the 531X307LTBAFG1’s readings drift beyond ±0.2°C.

Replacement Note: Only use Emerson-authorized 531X307LTBADG1 spares—third-party boards lack Emerson’s cold-junction compensation, leading to inaccurate temperature data.

Related Model Recommendations

531X307LTBAFG1: Low-temperature analog input module—receives conditioned signals from 531X307LTBADG1 for 24-bit A/D conversion and DCS integration.

531X307LTBAKG1: LAN I/O terminal board—complements 531X307LTBADG1 in mixed analog/digital systems (e.g., temperature + freezer door status monitoring).

531X101PAMIG1: Ovation main controller—processes digital data from 531X307LTBAFG1 (conditioned by 531X307LTBADG1) to execute control logic.

531X201PWRDG1: Redundant power supply—provides stable 24 V DC to 531X307LTBADG1’s logic circuit, critical for 24/7 cold-storage systems.

531X302DCIADG1: Digital input module—pairs with 531X307LTBADG1 to add discrete signal monitoring (e.g., freezer door open/closed) to low-temperature systems.

531X304DCOADG1: Digital output module—acts on controller commands (triggered by 531X307LTBADG1-conditioned data) to activate alarms or refrigeration compressors.