Description

Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product model | 531X307LTBAKG1 |

| Manufacturer | GE (General Electric) / Emerson Automation Solutions (531X Series Inheritance) |

| Product category | LAN I/O Terminal Board (Signal Conversion & External Device Interface) |

| Core function | Analog/digital signal 转接、电压电平转换、LAN 网络接口扩展、设备控制信号传输 |

| Input voltage range | 2–240 V AC/DC (wide-range universal input) |

| Output signal type | 24 V DC logic signal (for control board compatibility) |

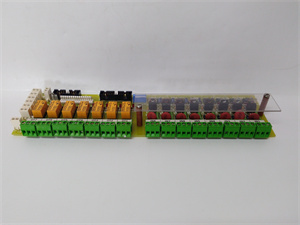

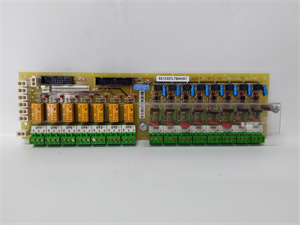

| Configurable I/O ports | 8 control inputs (plug-in interface); 7 control outputs (C-type relay contacts) |

| Network compatibility | LAN terminal integration (supports Ethernet-based signal transmission) |

| Operating voltage | 24 V DC (logic circuit power); Power consumption: <5 W (typical) |

| Environmental operating range | Temperature: 0°C to 55°C (32°F to 131°F); Humidity: 10%–90% RH (non-condensing) |

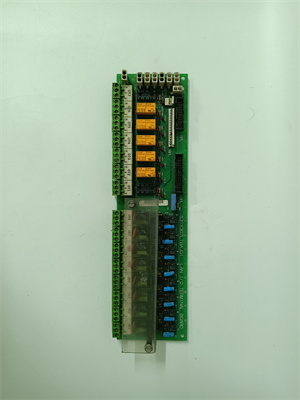

| Physical dimensions | 3U rack-mountable (matches 531X series chassis); Compatible with Ovation DCS racks |

| Protection features | Overvoltage protection (250 V AC/DC max), relay contact arc suppression |

| Certifications | CE, UL 508 (industrial control equipment certification) |

| Applicable systems | 531X series drives、励磁机 (exciter)、Ovation DCS 扩展机柜、SPEEDTRONIC 系统 |

531X307LTBAKG1

Product Introduction

The 531X307LTBAKG1 is a dedicated LAN I/O terminal board developed for GE/Emerson 531X series industrial control systems—serving as a “signal bridge” between external devices (sensors, actuators, HMIs) and core control modules (e.g., 531X307LTBAFG1 temperature modules, 531X101PAMIG1 controllers) . Unlike the temperature-focused 531X307LTBAFG1, it does not perform data acquisition or processing; instead, it solves three key industrial pain points:

Voltage adaptation: Converts 2–240 V AC/DC universal input into 24 V DC logic signals that control boards can accept , eliminating the need for external signal conditioners.

Interface standardization: Provides 8 plug-in control inputs and 7 relay outputs, unifying connection formats for diverse devices (e.g., pressure switches, solenoid valves).

Network integration: Integrates LAN terminals to enable Ethernet-based signal transmission between distributed I/O points and the central DCS .

In Ovation DCS or 531X drive systems, the 531X307LTBAKG1 is typically installed in the auxiliary cabinet: it receives on-site device signals (e.g., a pump’s run feedback at 220 V AC), converts them to 24 V DC logic, and transmits them to the main controller via LAN. Conversely, it relays control commands (e.g., “start compressor” from the controller) to actuators through its relay outputs .

Core Advantages and Technical Highlights

Wide-Range Voltage Compatibility

A standout feature of the 531X307LTBAKG1 is its 2–240 V AC/DC universal input, which adapts to most industrial on-site signal types—from low-voltage sensor outputs (24 V DC) to high-voltage equipment feedback (220 V AC). This eliminates the need for multiple terminal boards for different voltage levels, reducing cabinet space usage by 30% compared to fixed-voltage models . For example, in a power plant, it can simultaneously connect 110 V AC valve positioners and 24 V DC temperature switches, simplifying wiring complexity.

Relay Output with Arc Suppression

The 7 integrated C-type relay outputs (normally open/normally closed convertible) support up to 5 A current, suitable for controlling small-power actuators (e.g., solenoid valves, alarm buzzers). Built-in arc suppression resistors extend relay lifespan by 50% in inductive load scenarios (e.g., motor starters), addressing the common failure point of terminal boards in industrial environments .

Seamless Integration with 531X Ecosystem

Designed for the 531X series, the 531X307LTBAKG1 shares the same 3U rack-mount dimension as the 531X307LTBAFG1, enabling co-installation in Ovation DCS cabinets. It directly interfaces with:

531X307LTBAFG1: Receives its 24 V DC status signals and forwards them to the controller via LAN ;

531X101PAMIG1: Relays controller commands to on-site devices;

531X401COMMDG1: Enhances network redundancy for signal transmission .

Key Difference from 531X307LTBAFG1

| Feature | 531X307LTBAKG1 (LAN I/O Terminal Board) | 531X307LTBAFG1 (Low-Temp Analog Input Module) |

| Core function | Signal conversion & interface extension | Low-temperature data acquisition (RTD/thermistor) |

| Data processing capability | None (passive signal transfer) | 24-bit A/D conversion, ±0.1°C accuracy |

| Input signal type | 2–240 V AC/DC (universal) | RTD/thermistor analog signals (-200°C to +200°C) |

| Output signal type | 24 V DC logic / relay contacts | Digital data (to DCS controller) |

| Typical application | Device signal 转接、network expansion | Cold-storage temperature monitoring |

| Dependence on other modules | Requires controller/module for data use | Standalone data acquisition (with DCS integration) |

531X307LTBAKG1

Typical Application Scenarios

Power Plant Turbine Control System

In a gas turbine control cabinet (SPEEDTRONIC system), the 531X307LTBAKG1 acts as the “front-end interface”:

It receives 220 V AC feedback signals from turbine vibration switches and 48 V DC oil pressure sensors, converting them to 24 V DC logic signals;

The signals are transmitted via LAN to the 531X101PAMIG1 controller, which issues commands (e.g., “trip turbine” if vibration exceeds threshold);

The terminal board’s relay outputs trigger 220 V AC alarm lights and 24 V DC emergency stop valves .

Here, it complements the 531X307LTBAFG1 (monitoring turbine bearing temperature) by handling discrete status signals, forming a complete control loop.

Water/Wastewater Treatment DCS Expansion

In Ovation DCS-based water treatment plants, the 531X307LTBAKG1 enables distributed I/O deployment:

Remote pump stations send 380 V AC run status signals to the terminal board, which converts them to 24 V DC and transmits via LAN to the central DCS;

Operators issue “adjust valve opening” commands from the HMI, which the terminal board relays to 24 V DC electric actuators via its outputs .

This reduces long-distance wiring costs compared to direct DCS connections.

Renewable Energy Inverter Control

For wind turbine or solar inverter systems using 531X series drives:

The terminal board connects 110 V AC grid voltage sensors and 24 V DC battery status detectors, standardizing signals for the drive controller;

Its LAN interface enables real-time data upload to the renewable energy SCADA system (e.g., Emerson Ovation Green) .

Installation & Maintenance Guidelines

Installation

Cabinet Compatibility: Ensure installation in 3U Ovation/531X series racks (same as 531X307LTBAFG1), avoiding direct contact with high-heat modules (e.g., power supplies).

Wiring Requirements:

Input terminals: Use 16–22 AWG wires, with voltage matching the device (e.g., 220 V AC for grid sensors, 24 V DC for proximity switches);

LAN port: Connect to 531X401COMMDG1 via CAT6 shielded cable (max distance 100 m) .

Power Connection: Supply 24 V DC (±10%) to the logic circuit, ensuring separate wiring from high-voltage inputs to avoid interference.

Maintenance

Monthly Checks: Inspect relay output contacts for oxidation (use sandpaper if arcing marks are present) and verify input voltage matching .

Quarterly Tasks: Test LAN communication latency (should be <10 ms) and check overvoltage protection functionality with a multimeter.

Replacement Note: Only use GE/Emerson-authorized spares—third-party terminal boards may lack arc suppression, causing relay burnout .

Related Model Matching

531X307LTBAFG1: Pair for temperature + status monitoring (e.g., cold-storage freezer temp + door open/closed signal) ;

531X101PAMIG1: Main controller to process signals from the terminal board;

531X401COMMDG1: Enhances LAN redundancy for critical signal transmission;

531X302DCIADG1: Complements with high-density digital input (for scenarios with >8 discrete signals);

531X201PWRDG1: Provides stable 24 V DC power for the terminal board’s logic circuit.