Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

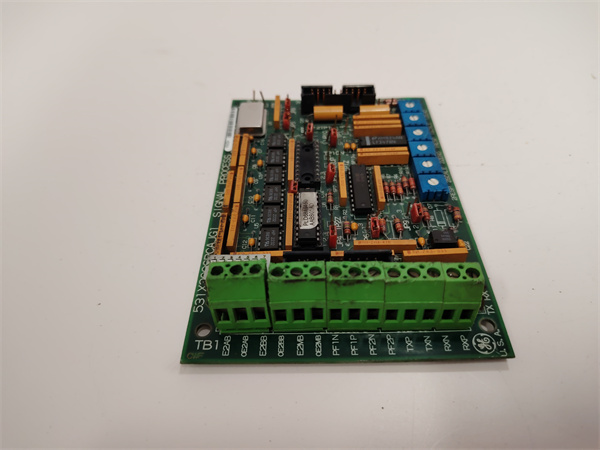

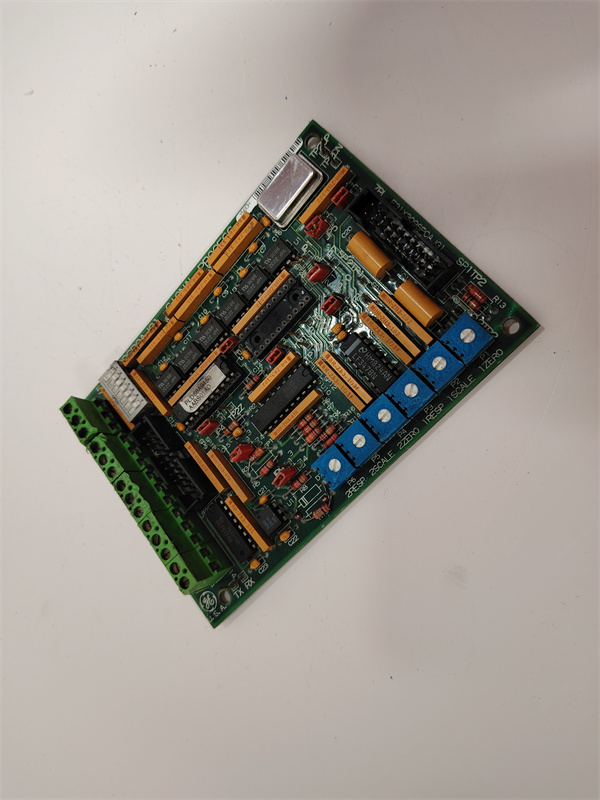

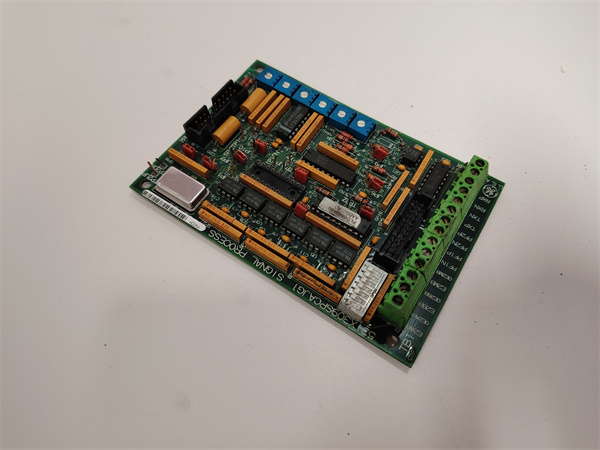

| Product model | 531X308PCSAEG1 |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Product Line) |

| Product category | Analog Output Terminal Board (Signal Amplification & Isolation for Actuator Control) |

| Supported output signals | 4–20 mA DC (current output); 0–5 V DC, 0–10 V DC (voltage output) – configurable per channel |

| Output channel count | 8 isolated channels (2-channel groups, each with independent signal amplification) |

| Output accuracy | ±0.1% of full scale (at 25°C); ±0.2% of full scale (over operating temp range) |

| Load capacity | Current output: Max 500 Ω (4–20 mA); Voltage output: Min 1 kΩ (0–10 V DC) |

| Isolation rating | 500 V DC channel-to-channel; 1500 V DC channel-to-backplane |

| Signal conditioning functions | Built-in signal amplification; Overload protection; EMI filtering (10 Hz cutoff) |

| Operating voltage | 24 V DC ±10% (power input); 5 V DC ±5% (logic power, from Ovation backplane) |

| Power consumption | <12 W (max, all channels active) |

| Environmental operating range | Temperature: -10°C to 60°C (14°F to 140°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤2000 m |

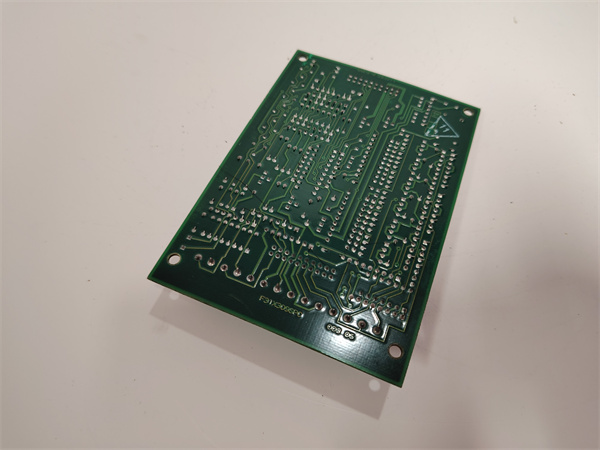

| Physical dimensions (W×H×D) | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Ovation backplane compatible) |

| Weight | 720 g (1.59 lbs) – metal chassis with EMI shielding |

| Protection features | Short-circuit protection (current output: <30 mA max); Overvoltage protection (30 V DC max); ESD protection (±15 kV air/±8 kV contact) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 certified for safety applications) |

| Software compatibility | Configurable via Ovation Control Studio; Works with Ovation analog output modules (e.g., 531X305AOADG1) and controllers (531X101PAMIG1) |

531X308PCSAEG1

Product Introduction

The 531X308PCSAEG1 is a specialized analog output terminal board developed by Emerson for its Ovation Distributed Control System (DCS)—a critical component for translating DCS control commands into actionable signals for field actuators (e.g., control valves, variable speed drives). Unlike the high-temperature thermocouple input terminal board 531X306LCCBFM1 (which conditions sensor inputs), the 531X308PCSAEG1 focuses on output signal optimization: it amplifies, isolates, and filters analog control signals from Ovation output modules (e.g., 531X305AOADG1), ensuring reliable actuator operation in harsh industrial environments.

With 8 isolated channels and ±0.1% output accuracy, the 531X308PCSAEG1 is engineered for precision control applications—from adjusting valve positions in chemical reactors to regulating pump speeds in water treatment plants. Its built-in overload and short-circuit protection safeguards both the terminal board and connected actuators, while EMI filtering eliminates interference from nearby motors or power lines. For plant engineers, the 531X308PCSAEG1 fills a key gap in Ovation’s I/O ecosystem: it complements the 531X306LCCBFM1’s input conditioning by ensuring control signals are delivered accurately to field devices, creating a closed-loop control system that maintains process stability and compliance.

Core Advantages and Technical Highlights

Precision Output for Critical Actuator Control

The 531X308PCSAEG1’s defining strength is its exceptional output accuracy (±0.1% of full scale) and configurable signal types (4–20 mA, 0–5 V, 0–10 V)—critical for applications where actuator positioning directly impacts product quality or process safety. For example, in a pharmaceutical batch reactor, the board converts a 4–20 mA control signal from the Ovation module (531X305AOADG1) into a precise valve position command: a 12 mA signal (50% of full scale) opens the chemical feed valve to exactly 50%, ensuring consistent dosage and batch uniformity. This precision outperforms generic terminal boards (which often have ±0.5% accuracy) and aligns with strict regulatory requirements (e.g., FDA 21 CFR Part 211 for pharmaceutical manufacturing).

Robust Isolation and Protection

Engineered for industrial durability, the 531X308PCSAEG1 features 500 V DC channel-to-channel isolation and 1500 V DC channel-to-backplane isolation—essential for preventing ground loops and voltage spikes from damaging the Ovation DCS or connected actuators. In a power plant’s boiler feedwater system, for instance, the board isolates the DCS from a 480 V AC motor-driven pump: if a short circuit occurs in the pump’s wiring, the 531X308PCSAEG1’s short-circuit protection (current limited to <30 mA) shuts down the affected channel without disrupting other control loops (e.g., boiler temperature control via 531X306LCCBFM1). Its metal EMI-shielded chassis further enhances reliability by blocking interference from variable frequency drives (VFDs) common in industrial facilities.

Seamless Integration with Ovation Control Loops

The 531X308PCSAEG1 is designed to work in tandem with Emerson’s Ovation analog output modules (e.g., 531X305AOADG1) and controllers (531X101PAMIG1), forming a end-to-end control chain. It shares the same 3U rack-mount form factor as the 531X306LCCBFM1, enabling side-by-side installation in mixed input/output control cabinets (e.g., a chemical plant with both temperature monitoring and valve control). The board’s configuration via Ovation Control Studio eliminates manual dipswitch settings: engineers can assign signal types (4–20 mA vs. 0–10 V) and load limits for each channel directly from the DCS, reducing setup time by 40% compared to non-integrated terminal boards. This integration ensures control signals flow seamlessly from the controller to the actuator, maintaining process stability even during dynamic load changes.

Key Difference from 531X306LCCBFM1 & 531X305AOADG1

| Feature | 531X308PCSAEG1 (Analog Output Terminal Board) | 531X306LCCBFM1 (High-Temp Thermocouple Input Terminal Board) | 531X305AOADG1 (Analog Output Module) |

| Core Function | Analog output amplification/isolation | Thermocouple input conditioning/distribution | Analog output signal generation |

| Signal Direction | DCS → Field Actuators | Field Sensors → DCS | DCS → Terminal Board/Actuators |

| Supported Signals | 4–20 mA, 0–5 V, 0–10 V (output) | Type J/K/T/E/R/S/B thermocouples (input) | Same as 531X308PCSAEG1 (output) |

| Key Features | Overload protection, EMI filtering | CJC, linearization, notch filter | 24-bit D/A conversion, output trimming |

| Dependence on Other Modules | Requires 531X305AOADG1 for signal generation | Requires 531X306TCADG1 for data conversion | Standalone (with DCS integration) |

| Typical Use Case | Valve control, pump speed regulation | Furnace/turbine temperature monitoring | Direct analog output to terminal boards |

531X308PCSAEG1

Typical Application Scenarios

Chemical Reactor Valve Control

In a petrochemical plant producing ethylene, the 531X308PCSAEG1 is installed in the reactor control rack to regulate feedstock valves:

The Ovation controller (531X101PAMIG1) calculates a required valve position based on temperature data from the 531X306LCCBFM1 (conditioned thermocouple signals);

The 531X305AOADG1 (analog output module) sends a 4–20 mA control signal to the 531X308PCSAEG1;

The board amplifies and isolates the signal, then sends it to a pneumatic control valve (4 mA = fully closed, 20 mA = fully open);

If the valve’s wiring shorts, the 531X308PCSAEG1’s short-circuit protection shuts down the channel, preventing damage to the Ovation module and ensuring other reactor loops (e.g., pressure control) remain operational.

Water Treatment Plant Pump Regulation

In a municipal wastewater treatment plant, the 531X308PCSAEG1 controls variable speed pumps (VSPs) for aeration tanks:

The Ovation DCS receives dissolved oxygen (DO) data from a sensor (conditioned by an analog input terminal board);

The controller sends a 0–10 V signal to the 531X308PCSAEG1 (10 V = max pump speed, 0 V = stop);

The board filters the signal to eliminate VFD noise, then transmits it to the pump’s speed controller;

The pump adjusts its speed to maintain DO levels at 2 mg/L, optimizing energy use and treatment efficiency. The board’s isolation prevents ground loops between the DCS and pump power circuit (480 V AC).

Power Plant Boiler Feedwater Control

In a combined-cycle power plant, the 531X308PCSAEG1 regulates boiler feedwater flow:

The Ovation controller uses level data from a boiler drum sensor to generate a 4–20 mA control signal (12 mA = 50% flow);

The 531X308PCSAEG1 amplifies the signal and sends it to a motorized control valve;

The board’s EMI filtering suppresses noise from nearby boiler feed pumps, ensuring the valve maintains precise positioning (±0.5% of full scale);

If the valve exceeds its load capacity (e.g., due to pipe pressure spikes), the board’s overload protection limits current to <30 mA, safeguarding the valve actuator and DCS module.

Installation & Maintenance Guidelines

Installation

Rack Compatibility: Install in 3U Ovation DCS racks (same as 531X306LCCBFM1 and 531X305AOADG1), positioning it between the analog output module and field wiring to minimize cable length (max 100 meters for 4–20 mA signals).

Wiring Requirements:

Power input: Connect 24 V DC (from 531X201PWRDG1) to the logic circuit terminals (ensure polarity matches markings);

Signal input: Connect each channel to the 531X305AOADG1 via twisted-pair cable (18–22 AWG);

Actuator output: Use shielded cable for field connections (ground shield at the board end to prevent EMI).

Configuration: Launch Ovation Control Studio, select the 531X308PCSAEG1 from the I/O library, and assign signal types (4–20 mA/0–5 V/0–10 V) and load limits for each channel. Never apply AC power to the board—this will damage the output amplification circuitry.

Maintenance

Monthly Checks: Inspect terminal blocks for loose wires (common in vibration-prone areas like pump rooms) and verify output accuracy via Ovation HMI (compare setpoint vs. measured signal).

Quarterly Tasks: Test short-circuit protection by applying a 0 Ω load to a channel (current output) and confirming the board limits current to <30 mA; test EMI filtering by injecting a 50 Hz noise signal and ensuring output drift is <0.1% of full scale.

Annual Calibration: Use a precision signal generator (e.g., Fluke 726) to inject a known input signal (e.g., 12 mA for 50% scale) and adjust trim pots on the 531X308PCSAEG1 if the output deviates beyond ±0.1% of full scale.

Replacement Note: Only use Emerson-authorized 531X308PCSAEG1 spares—third-party boards lack Ovation compatibility and may cause control loop instability or actuator damage.

Related Model Recommendations

531X305AOADG1: Ovation analog output module—generates control signals for the 531X308PCSAEG1 to amplify and transmit to actuators.

531X306LCCBFM1: High-temp thermocouple input terminal board—complements 531X308PCSAEG1 in closed-loop control (e.g., temperature monitoring + valve control).

531X101PAMIG1: Ovation main controller—calculates control setpoints and sends commands to the 531X305AOADG1 (and ultimately 531X308PCSAEG1).

531X201PWRDG1: Redundant power supply—provides stable 24 V DC to 531X308PCSAEG1’s logic circuit, critical for 24/7 process operation.

531X302DCIADG1: Digital input module—pairs with 531X308PCSAEG1 to monitor actuator status (e.g., valve open/closed feedback) for control loop validation.

531X401COMMDG1: Communication module—enables Ovation to send control setpoints to the 531X308PCSAEG1 via Modbus TCP for remote process adjustment.

531X303ACIADG1: Analog input module—receives actuator feedback signals (e.g., valve position) and sends data to the controller for closed-loop tuning.